Swiss-type automatic lathes, also known as sliding headstock lathes, are highly precise automated machine tools that are widely used in precision manufacturing, especially for high-accuracy, small-batch, multi-operation parts. With their unique processing mechanism, Swiss-type lathes can efficiently manufacture complex parts in a short time. This article provides a comprehensive introduction to the processing scope, available sizes, and the advantages and disadvantages of Swiss-type automatic lathes.

Ⅰ. Processing Scope of Swiss-Type Lathes

Swiss-type lathes have an extensive range of capabilities, from simple turning to complex multi-operation machining. Their applications include:

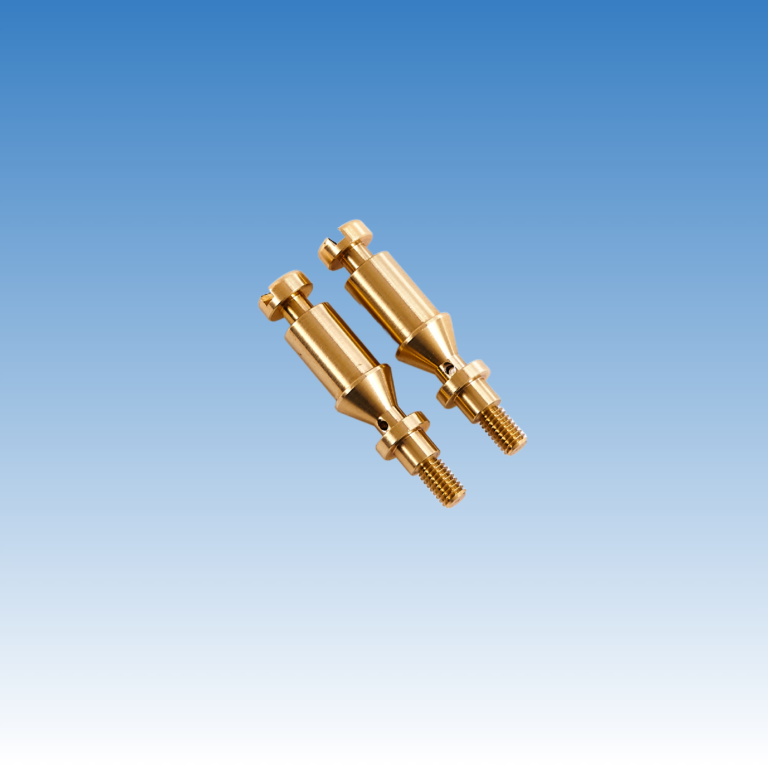

- Precision Shaft Parts Swiss-type lathes are ideal for processing precision shaft parts. By synchronizing the motion of the cutting tool and the workpiece, they can achieve high precision in machining outer diameters, inner bores, end faces, threads, and more. Common applications include precision shafts, valve bodies, pump bodies, and similar parts.

- Complex Shaped Parts Due to the ability to equip Swiss-type lathes with multiple tool positions and multi-axis control systems, these machines can simultaneously perform multiple operations. This makes them suitable for processing complex parts with grooves, threads, inner and outer diameters, and other intricate features.

- Small-Batch Production Swiss-type lathes excel in small-batch production. Their high precision and automation enable the efficient production of high-quality parts in a short amount of time, making them particularly suited for the manufacturing of precision components.

- High-Precision Mass Production In high-volume production of precision components, Swiss-type lathes can maintain extremely high processing precision and production efficiency, minimizing errors caused by manual operation.

- Material Versatility Swiss-type lathes are capable of machining a wide range of materials, including steel, aluminum, copper, plastic, and more. They are particularly effective in machining hard materials like stainless steel and titanium alloys.

Ⅱ. Size Capabilities of Swiss-Type Lathes

The size capabilities of Swiss-type lathes depend on the model and configuration. Typically, they are suitable for machining parts as small as a few millimeters in diameter and as long as several hundred millimeters. Specific size capabilities include:

- Workpiece Diameter: The typical maximum diameter for most Swiss-type lathes ranges from 25 mm to 32 mm, with some high-end models capable of handling diameters up to 50 mm. For smaller workpieces, Swiss-type lathes perform exceptionally well in terms of precision and efficiency.

- Processing Length: The usual processing length for Swiss-type lathes is between 100 mm and 400 mm, which is ideal for machining long, slender parts. For longer workpieces, Swiss-type lathes can still ensure high precision.

- Tool Configuration: Swiss-type lathes typically have up to 8 tool positions. Various tools can be used simultaneously to perform turning, drilling, tapping, milling, and other operations to meet the requirements of complex part designs.

- Precision: Swiss-type lathes can achieve a machining precision of ±0.005 mm to ±0.01 mm, making them suitable for parts requiring high levels of precision.

III. Advantages of Swiss-Type Lathes

Swiss-type lathes offer numerous advantages, including:

- High Precision Swiss-type lathes are known for their high processing accuracy, ensuring consistent part dimensions and stability. In small-batch production, they can guarantee the same high precision across each part.

- High Efficiency With their high level of automation, Swiss-type lathes can perform multiple operations simultaneously, eliminating the need for tool changes between steps, significantly boosting production efficiency.

- Suitable for Complex Part Processing These lathes are capable of performing multi-operation machining with multiple tools, enabling them to manufacture complex parts with features such as threads, grooves, and end faces.

- Reduced Human Intervention Swiss-type lathes are highly automated, which reduces the need for manual intervention. This minimizes human errors and improves the consistency and stability of the production process.

- Versatility with Materials Swiss-type lathes can handle a wide range of materials, including metals and plastics, and excel in machining hard materials like stainless steel and titanium alloys.

Ⅳ. Disadvantages of Swiss-Type Lathes

Despite their many advantages, Swiss-type lathes have some limitations and disadvantages:

- High Initial Investment Swiss-type lathes can be costly, especially high-precision CNC models. For smaller companies, the initial investment may be significant and require substantial capital.

- High Skill Requirement Although Swiss-type lathes are highly automated, they still require skilled operators for setup and programming. Particularly for complex part machining, operators must possess extensive experience and technical knowledge.

- Size Limitations Swiss-type lathes are generally suited for machining smaller diameters and medium-length parts. For larger or extremely complex parts, their capabilities may be limited.

- Cutting Speed Limitations While Swiss-type lathes provide high precision, their cutting speeds tend to be more conservative compared to other high-speed machining equipment. In some cases, this can result in lower machining efficiency.

Ⅴ. Conclusion

Swiss-type lathes, with their high precision, efficiency, and multi-operation capabilities, are widely used in precision machining, particularly for small-batch production of complex parts. While the high initial investment and technical requirements may pose challenges, the advantages of Swiss-type lathes in terms of precision and quality are undeniable. As technology advances and the performance of these machines continues to improve, the scope of their applications is expected to broaden, bringing further innovations and efficiency gains in precision manufacturing.