Marine precision fasteners play a critical role in shipbuilding and maintenance. Their main function is to connect key parts of the ship, ensuring structural stability and sealing, while withstanding the harsh marine environment. Given the unique operating conditions of ships, marine precision fasteners must meet a range of stringent requirements. This article will comprehensively discuss the requirements, common materials, and their advantages and disadvantages for marine precision fasteners.

Ⅰ. Main Requirements for Marine Precision Fasteners

- High Strength and Fatigue Resistance

- Marine precision fasteners need to withstand the complex loads generated during a ship's operation, including wave impacts, vibration, and both dynamic and static loads. Therefore, they must have high strength and excellent fatigue resistance.

- Outstanding Corrosion Resistance

- Ships operate in a marine environment with high salinity and humidity, so fasteners must resist saltwater corrosion and electrochemical corrosion, particularly when in direct contact with seawater.

- High and Low-Temperature Resistance

- Different parts of a ship (e.g., engine rooms or polar regions) may face extreme temperature conditions. The materials of fasteners must meet the challenges of both high and low temperatures.

- Excellent Sealing Ability

- Fasteners used in the hull and piping systems must ensure reliable sealing performance to prevent seawater leakage or fluid leakage.

- Vibration and Shock Resistance

- Ships generate intense vibration and shock loads during operation, so fasteners must maintain a secure connection to prevent loosening or breakage.

- Lightweight Design

- While meeting strength requirements, fasteners should be designed to be lightweight to reduce the overall weight of the ship, thereby improving fuel efficiency.

- Ease of Installation and Maintenance

- Fasteners should be designed for quick installation and easy replacement, minimizing downtime for ship maintenance.

Ⅱ. Common Materials for Marine Precision Fasteners

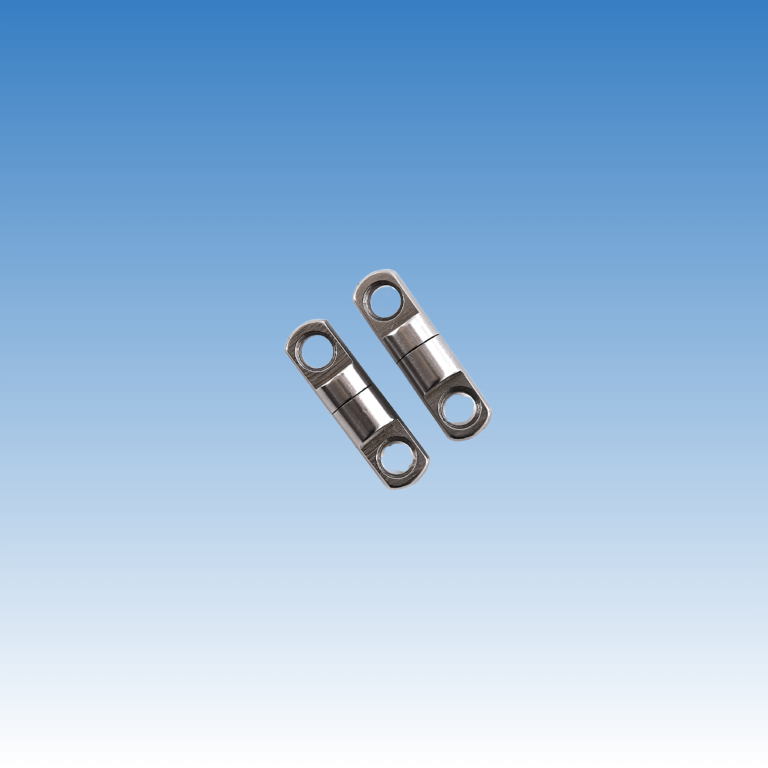

- Stainless Steel

- Common Grades: 316, 316L, 2205 (duplex stainless steel)

- Advantages:

- Excellent corrosion resistance, especially for environments exposed to saltwater and seawater.

- High strength and toughness, suitable for dynamic load-bearing applications.

- Disadvantages:

- Higher cost compared to some other materials.

- May exhibit brittleness at low temperatures.

- Applications:

- External equipment connections, deck bolts, propeller components.

- Nickel-Based Alloys

- Common Grades: Monel 400, Inconel 718

- Advantages:

- Extremely strong corrosion resistance, suitable for parts in long-term contact with seawater.

- Excellent performance at high temperatures and high strength.

- Disadvantages:

- Very high material and processing costs.

- Applications:

- Critical components, such as propeller shafts and propeller fasteners.

- Carbon Steel (Hot-Dip Galvanized or Coated)

- Advantages:

- Low material cost, good machinability.

- Coatings (e.g., galvanization) provide some corrosion resistance.

- Disadvantages:

- Corrosion resistance is inferior to stainless steel or nickel alloys; coatings may fail, leading to corrosion.

- Applications:

- Internal ship body parts, non-critical fasteners for short-term use.

- Advantages:

- Titanium Alloys

- Common Grades: Ti-6Al-4V

- Advantages:

- Exceptional corrosion resistance and strength-to-weight ratio.

- Suitable for high-strength, high-fatigue applications.

- Disadvantages:

- Expensive material, difficult to machine.

- Applications:

- High-performance fasteners for advanced ships, deep-sea exploration equipment, and high-end yachts.

- Aluminum Alloys

- Advantages:

- Low density helps reduce ship weight.

- Good corrosion resistance, especially with anodized finishes.

- Disadvantages:

- Lower strength compared to other materials, not ideal for high-load applications.

- Applications:

- Fasteners for small ships or low-load components.

- Advantages:

III. Advantages and Disadvantages of Marine Precision Fasteners

- Advantages:

- High Performance for Extreme Environments: Marine precision fasteners are designed to perform well in extreme conditions, including high and low temperatures, high humidity, and saltwater environments.

- Custom Design: Fasteners can be specially designed to meet various load-bearing and sealing requirements, providing tailored solutions for different marine applications.

- Extended Service Life: The use of high-quality materials and advanced coatings significantly reduces corrosion and wear, increasing the service life of fasteners.

- Disadvantages:

- High Cost: Premium materials, such as nickel alloys and titanium, come with high material and manufacturing costs.

- Complex Maintenance: Some fasteners require regular inspections and maintenance, especially those with coatings that can degrade over time.

- Installation Challenges: Certain precision fasteners require specialized tools or techniques for installation and removal, adding to labor costs and complexity.

Ⅳ. Future Trends in Marine Precision Fasteners

- Development of New Materials:

- New composite materials and advanced alloys will continue to be developed to improve strength, corrosion resistance, and weight reduction. These materials may be more cost-effective while providing even better performance.

- Smart Fasteners:

- The integration of sensors into fasteners will enable real-time monitoring of the connection's status, such as detecting loosening, fatigue, or corrosion. This can greatly enhance the safety and operational efficiency of the ship.

- Green Manufacturing:

- With increasing environmental regulations, there will be a focus on more sustainable manufacturing practices, reducing the use of harmful materials like lead, and optimizing production to minimize waste.

- Surface Treatment Innovations:

- Advanced surface treatment technologies, such as Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) coatings, will further enhance the wear and corrosion resistance of fasteners.

Ⅴ. Conclusion

Marine precision fasteners play a vital role in ensuring the safety, reliability, and efficiency of ships. Choosing the right materials and designs can significantly improve the overall performance of the ship while reducing maintenance costs and extending the lifespan of critical components. As material science and manufacturing technologies continue to advance, marine precision fasteners will become lighter, stronger, smarter, and more environmentally friendly, providing even greater support to the maritime industry in the years to come.