Introduction

The DIN 509 standard, established by the German Institute for Standardization (Deutsches Institut für Normung, DIN), is a technical specification for measuring the thickness of metallic coatings. It is widely used in mechanical manufacturing, the automotive industry, electronics, and precision engineering. For precision fasteners, controlling coating thickness directly affects their corrosion resistance, mechanical performance, and long-term reliability. This article explores the application of the DIN 509 standard in precision fasteners, covering its significance, measurement methods, quality control requirements, and future development trends.

Ⅰ. Importance of the DIN 509 Standard

1.1 Ensuring Corrosion Resistance of Fasteners

Fasteners are often used in harsh environments, such as high humidity, chemical exposure, or high-temperature conditions. The DIN 509 standard specifies methods for measuring metallic coating thickness to ensure a uniform and sufficiently thick layer, enhancing the corrosion resistance of fasteners and extending their service life.

1.2 Impact on Mechanical Performance

Excessive or insufficient coating thickness can affect the mechanical performance of fasteners. Overly thick coatings may lead to fit tolerance deviations, while excessively thin coatings may fail to provide adequate protection. The DIN 509 standard helps optimize coating thickness to maintain both high strength and corrosion resistance.

1.3 Standardization for Product Interchangeability

DIN 509 provides a unified technical specification, ensuring that fasteners produced in different regions maintain consistent coating quality. This improves product compatibility and competitiveness in the global market.

Ⅱ. Measurement Methods for Coating Thickness in the DIN 509 Standard

The DIN 509 standard specifies various methods for measuring coating thickness to meet different application requirements. The primary methods include:

2.1 Magnetic Method

This method is suitable for non-magnetic coatings on ferromagnetic materials, such as zinc or chrome coatings on steel. It measures variations in magnetic flux to determine coating thickness, offering high precision and non-destructive testing.

2.2 Eddy Current Method

This method is used for non-conductive coatings on conductive substrates, such as anodized layers on aluminum or copper. It relies on electromagnetic induction to measure coating thickness and is particularly useful for non-ferromagnetic materials.

2.3 X-ray Fluorescence (XRF) Method

This method is ideal for measuring multilayer coatings, enabling non-contact testing of different metal layers while analyzing their composition. It is widely used for high-precision fasteners in aerospace and medical applications.

2.4 Metallographic Cross-section Method

This method involves cutting a sample and observing the coating cross-section under a microscope to measure thickness. It is commonly used for laboratory precision analysis, providing detailed structural information about the coating.

Ⅲ. Application of DIN 509 Standard in Precision Fasteners

3.1 Coating Control for Threaded Fasteners

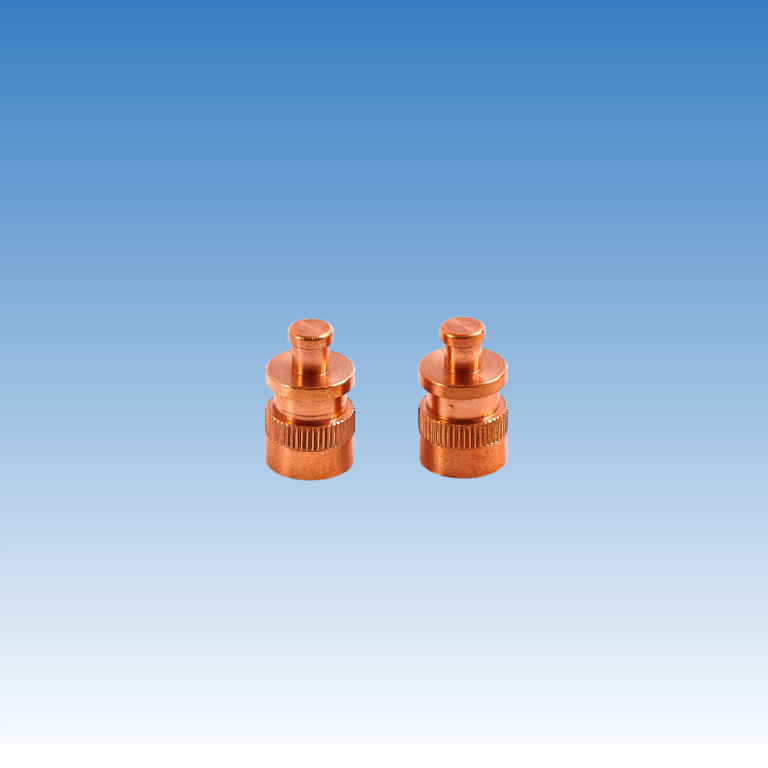

Threaded fasteners, such as bolts, nuts, and screws, are widely used in automotive, mechanical, and electronics industries. Their coating thickness directly affects thread fit accuracy and corrosion resistance. The DIN 509 standard ensures that coating thickness remains within an optimal range, preventing excessive thickness that complicates assembly or insufficient thickness that compromises corrosion protection.

3.2 High-Precision Fasteners in Aerospace

The aerospace industry demands highly reliable fasteners, where coatings must provide excellent protection without affecting dimensional accuracy. The DIN 509 standard helps manufacturers maintain both functional coatings and precise tolerances for aerospace fasteners.

3.3 Fasteners in Electronics and Precision Instruments

In electronics and precision instruments, fastener coatings must offer corrosion resistance without affecting electrical conductivity or electromagnetic performance. For example, nickel or gold-plated fasteners must strictly adhere to DIN 509 specifications to ensure stability in electronic devices.

Ⅳ. Quality Control Requirements in DIN 509

In addition to defining measurement methods, the DIN 509 standard includes strict quality control requirements, such as:

4.1 Process Control

During the coating process, periodic thickness measurements must be conducted to ensure compliance with standards. This includes both inline monitoring and laboratory sample analysis.

4.2 Statistical Quality Control (SQC)

Statistical methods are used to analyze measurement data, assessing the uniformity and consistency of coating thickness throughout the production process to improve product stability.

4.3 Failure Analysis

For fasteners that experience corrosion, peeling, or mechanical failure, DIN 509 prescribes failure analysis methods to identify root causes and improve manufacturing processes and material selection.

Ⅴ. Future Development Trends

5.1 Automation and Smart Inspection Technologies

With the rise of Industry 4.0, coating thickness measurement is advancing towards automation and digitalization. For example, inline X-ray inspection systems enable real-time monitoring, improving detection efficiency and precision.

5.2 Environmentally Friendly Coating Materials

Traditional coating materials such as chrome plating may contain environmentally hazardous elements. Future developments will focus on eco-friendly coatings, such as chromium-free passivation layers or nano-coatings, to comply with international environmental regulations.

5.3 Integration with Smart Manufacturing

DIN 509 will be increasingly integrated with smart manufacturing technologies to create a closed-loop control system, allowing coating thickness measurement to be synchronized with production processes in real time. This will enhance product quality and production efficiency.

Ⅵ. Conclusion

The DIN 509 standard plays a crucial role in the precision fastener industry by providing guidelines for coating thickness control, corrosion resistance, and quality inspection. By selecting appropriate measurement methods, optimizing production processes, and integrating smart manufacturing technologies, manufacturers can ensure compliance with international standards and improve product competitiveness. As environmental regulations tighten and inspection technologies advance, DIN 509 will continue to play a vital role in a broader range of precision manufacturing applications.