Electrophoretic deposition (EPD), also known as e-coating or electrophoretic painting, is a widely adopted surface treatment process for metal components. Due to its advantages in corrosion resistance, uniform coating, strong adhesion, and environmental friendliness, it has become a preferred finishing solution across industries such as automotive, home appliances, hardware, construction, industrial machinery, and electronics.

This article provides a comprehensive overview of electrophoretic coating technology, including its working principle, process steps, key benefits, and application scope, helping manufacturers, engineers, and buyers better understand how e-coating can enhance product performance and surface protection.

What Is Electrophoretic Deposition?

Electrophoretic deposition (EPD) is a wet-paint coating process that uses an electric field to drive charged paint particles toward a conductive metal surface, where they form a thin, uniform, and corrosion-resistant coating. The process is suitable for metals such as steel, aluminum, zinc, and their alloys, and is known for high coverage efficiency—even on complex geometries.

First introduced in the 1960s in the automotive industry, e-coating has evolved into a mature, cost-effective, and environmentally friendly coating method for high-performance requirements.

How Electrophoretic Deposition Works

E-coating is based on principles of colloidal chemistry and electrochemistry. Here's how the process works:

- A water-based emulsion paint is prepared with dispersed polymer particles.

- The workpiece (metal part) is connected to either the anode or cathode and immersed in the e-coating bath.

- When voltage is applied, the charged paint particles migrate through the solution toward the metal surface.

- Once they reach the surface, they lose their charge and form a dense, uniform coating layer.

- The coated part is then rinsed and baked to cure and solidify the coating.

Types of Electrophoretic Coating

Based on the polarity of the coated metal part, e-coating can be divided into two main types:

- Anodic E-Coating

- The workpiece is connected as the anode.

- Negatively charged paint particles migrate and deposit on the part.

- Suitable for light-duty corrosion resistance.

- Common in appliances, furniture, and general hardware.

- Less resistant to acid corrosion compared to cathodic coatings.

- Cathodic E-Coating (Mainstream)

- The workpiece is connected as the cathode.

- Positively charged paint particles are deposited on the surface.

- Offers excellent corrosion resistance and durability.

- Widely used in automotive, industrial, and marine components.

- Requires less frequent maintenance of bath chemistry.

Conclusion: Cathodic e-coating is now the dominant choice in industrial applications due to its superior coating performance and long-term durability.

E-Coating Process Flow

A standard electrophoretic deposition process includes:

- Pre-treatment: Degreasing → Acid pickling → Surface conditioning → Phosphating → Rinsing

- E-Coating: Submersion in the e-coat tank and application of voltage

- Rinsing: To remove residual chemicals and loose particles

- Curing: Baking at 160–200°C for 20–30 minutes

- Inspection and Packaging: Quality check for coating thickness, appearance, adhesion

Key Benefits of Electrophoretic Coating

- Uniform Coating on Complex Shapes

E-coating ensures complete coverage—even on hidden areas, cavities, edges, and recesses—eliminating the dead zones found in spray painting or powder coating.

- Strong Adhesion and Excellent Corrosion Resistance

E-coat films bond tightly to the substrate and offer excellent resistance to salt spray, humidity, and chemicals. Corrosion protection of up to 500–1000+ hours in salt spray testing is achievable.

- Environmentally Friendly

E-coating uses water-based paints, emits low VOC (volatile organic compounds), and allows bath recycling, reducing environmental impact and improving workplace safety.

- Stable, Automated Process

Highly compatible with automated production lines, e-coating is ideal for mass production with consistent results.

- Compatible with Secondary Coatings

E-coat serves as an excellent primer for subsequent layers such as powder coating, wet painting, or topcoats, enabling multi-layer protection and decorative finishes.

Typical Performance Parameters (Cathodic E-Coating)

| Property | Typical Value |

| Coating Thickness | 15–35 µm (adjustable) |

| Salt Spray Resistance | ≥500 hours |

| Adhesion (Crosshatch Test) | Grade 0 (best) |

| Impact Resistance | ≥50 kg·cm |

| Gloss Level | 10–40% |

| Pencil Hardness | H–2H |

Common Applications of E-Coating

E-coating is widely used across industrial, automotive, and consumer sectors, particularly for metal parts with high durability or appearance requirements.

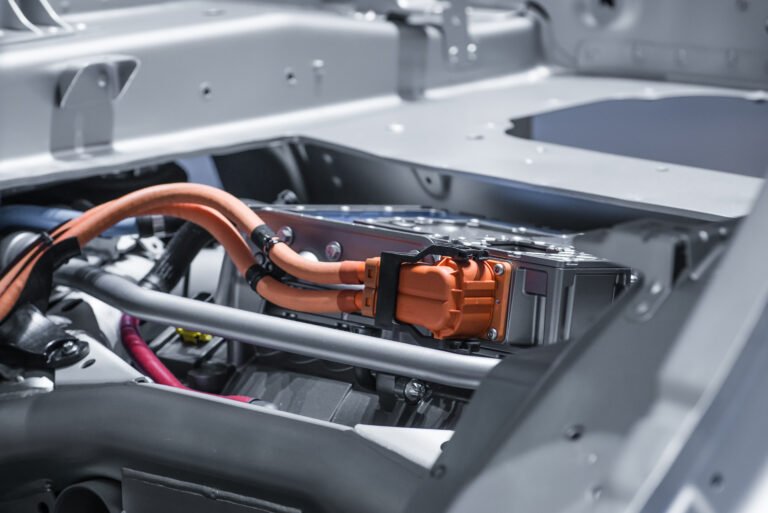

- Automotive Industry

- Chassis components: frames, arms, axles

- Engine bay parts: brackets, subframes

- Interior seat structures, hinges, bolts

- Wheels and brake caliper brackets

- Hardware and General Metal Parts

- Construction hardware, doors, locks

- Bicycle frames, fitness equipment

- Stainless steel or galvanized stamped parts

- Electrical and Appliance Industries

- Appliance frames, metal housings

- Electrical enclosures, heat sinks

- EV charging cabinet housings

- Industrial Equipment

- Agricultural and construction machinery parts

- Industrial fans, HVAC components

- Lifts, forklifts, and steel railings

Comparison: E-Coating vs Other Surface Treatments

| Method | Uniformity | Adhesion | Corrosion Resistance | Environmental Friendliness | Cost | Common Use |

| E-Coating | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★★ | Medium | Automotive primer, metal hardware |

| Powder Coating | ★★★☆☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | Low | Appliance exteriors, casings |

| Zinc Plating | ★★☆☆☆ | ★★★☆☆ | ★★★★☆ | ★☆☆☆☆ | Medium | Screws, brackets |

| Spray Painting | ★★★☆☆ | ★★★☆☆ | ★★☆☆☆ | ★★☆☆☆ | Low | General decorative coating |

| Anodizing | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | Medium-High | Aluminum profiles, electronics |

Limitations and Considerations

While electrophoretic coating offers many advantages, it also has limitations:

- Applicable only to conductive materials (primarily metals)

- Requires clean and thoroughly pretreated surfaces

- Higher initial investment than spray painting

- Color options are mainly limited to black and gray unless using specialty coatings

- Final baking stage may impact dimensional stability of thin parts

Conclusion

Electrophoretic deposition (E-Coating) is a high-performance, environmentally friendly surface treatment that provides uniform, corrosion-resistant, and tightly bonded coatings on a wide range of metal products. It is ideal for mass production environments that require durability, automation, and consistent quality.

With increasing demand for green manufacturing and corrosion-resistant finishes, e-coating is expected to play an even more significant role in automotive, EV, smart appliances, and industrial electronics industries.