In industries such as automotive, construction, heavy machinery, and energy, fasteners are critical components that must maintain integrity even in harsh environments. Corrosion of fasteners can lead to structural failure, equipment damage, and high maintenance costs. To assess and verify the corrosion resistance of surface treatments, the ISO 9227 salt spray test has become one of the most widely adopted international standards for fastener coating evaluation.

This article provides a comprehensive overview of the ISO 9227 salt spray test, including its principles, testing methods, classifications, and practical applications in the fastener industry. It is designed to help manufacturers, engineers, and procurement professionals understand how salt spray testing supports quality assurance and enhances anti-corrosion performance.

What Is the ISO 9227 Salt Spray Test?

ISO 9227, titled "Corrosion tests in artificial atmospheres — Salt spray tests", is an internationally recognized standard issued by the International Organization for Standardization (ISO). It defines accelerated laboratory testing methods to evaluate the corrosion resistance of metallic materials and their protective coatings.

The most recent version of the standard is ISO 9227:2017, which includes three major types of salt spray tests:

- Neutral Salt Spray (NSS)

- Acetic Acid Salt Spray (AASS)

- Copper-Accelerated Acetic Acid Salt Spray (CASS)

These test methods simulate corrosive environments such as marine atmospheres or industrial zones to accelerate corrosion processes in a controlled laboratory setting.

Purpose and Principle of Salt Spray Testing

The salt spray test exposes metal samples to a fine mist of salt solution inside a sealed chamber at a controlled temperature. The objective is to simulate corrosive attack and evaluate the protective performance of the coating over a shorter period than natural exposure.

Main goals of the test include:

- Assessing corrosion resistance of coatings such as zinc plating, Dacromet, GEOMET, and hot-dip galvanizing

- Comparing different surface treatment processes

- Supporting quality assurance and supplier evaluation

- Providing reference data for product life expectancy in corrosive environments

ISO 9227 Test Methods and Applicability

- Neutral Salt Spray (NSS)

- Solution: 5% NaCl, pH 6.5–7.2

- Temperature: 35 ± 2°C

- Use Case: Commonly used for evaluating zinc plating, Dacromet, hot-dip galvanized fasteners

- Application: Automotive bolts, construction screws, general hardware

- Acetic Acid Salt Spray (AASS)

- Solution: 5% NaCl + acetic acid, pH 3.1–3.3

- Temperature: 35 ± 2°C

- Use Case: Higher corrosion severity than NSS, suitable for aluminum alloys and decorative coatings

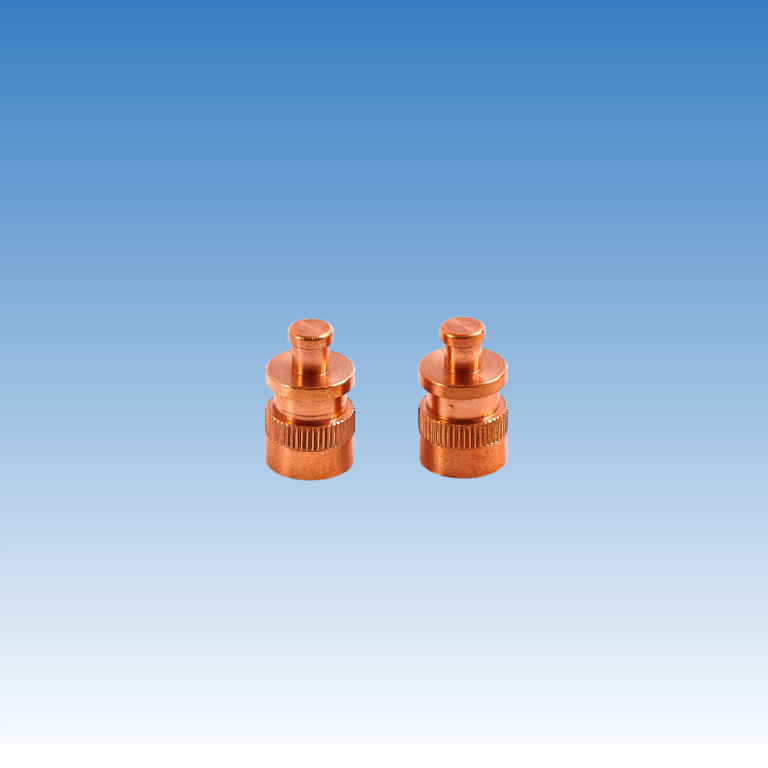

- Copper-Accelerated Acetic Acid Salt Spray (CASS)

- Solution: 5% NaCl + acetic acid + copper chloride

- Temperature: 50 ± 2°C

- Use Case: Highest corrosion severity, suitable for thick decorative chrome coatings and copper-based components

Applications of Salt Spray Testing in the Fastener Industry

- Evaluating Anti-Corrosion Coating Performance

Examples of typical performance benchmarks:

| Coating Type | Minimum Salt Spray Hours (No Red Rust) |

| Electro-galvanized | ≥ 72 hours |

| Zinc + chromate passivation | ≥ 120 hours |

| Dacromet coating | ≥ 480 hours |

| GEOMET coating | ≥ 720–1000 hours |

| Hot-dip galvanized | ≥ 240 hours |

- Supporting Quality Assurance and Customer Requirements

Many OEMs, especially in Europe and North America, require ISO 9227-compliant salt spray reports as part of quality acceptance protocols.

- Optimizing Surface Treatment Processes

By comparing salt spray test results of different coatings or post-treatment sealers, manufacturers can improve their finishing process and extend product lifespan.

- Correlating with Real-World Performance

While salt spray testing cannot directly predict outdoor life expectancy, it provides comparative data to assess performance trends in aggressive environments.

Common Misunderstandings About Salt Spray Testing

❌ Misconception 1: “The longer the salt spray test duration, the better.”

Not necessarily. Over-engineered coatings may increase costs or interfere with thread fit. Coating thickness should balance protection and function.

❌ Misconception 2: “Salt spray test results represent real-world durability.”

Salt spray testing only simulates chloride-driven corrosion in a single environment. For more accurate life predictions, tests like cyclic corrosion tests (ISO 16701) or outdoor exposure testing are recommended.

Salt Spray Test Procedure (ISO 9227)

- Sample Preparation

- Minimum of three test pieces

- Clean, oil-free, undamaged surfaces

- Chamber Settings

- Place samples at a 15–30° angle

- Set spray duration, solution concentration, and temperature

- Test Execution

- Run continuously for designated hours (e.g., 96h, 240h, 480h)

- Avoid opening the chamber during testing

- Post-Test Evaluation

- Observe for white rust, red rust, blistering, pitting, or coating failure

- Document results with photos, time-to-failure, and corrosion grade

Salt Spray Performance Levels by Coating Type

| Coating Type | Salt Spray Resistance (No Red Rust) |

| Electroplated Zinc (White/Blue) | ≥ 72 hours |

| Zinc + Passivation | ≥ 120 hours |

| Dacromet | ≥ 480 hours |

| GEOMET | ≥ 720–1200 hours |

| Hot-Dip Galvanizing | ≥ 240 hours |

Note: These are reference values. Requirements may vary by customer or industry.

ISO 9227 vs. Other Standards

| Standard | Origin | Description |

| ISO 9227 | International | Global standard for salt spray testing |

| ASTM B117 | USA | Equivalent test widely used in North America |

| GB/T 10125 | China | Chinese equivalent to ISO 9227 |

| DIN 50021 | Germany | Replaced by ISO 9227 for EU harmonization |

For global sourcing and compliance, ISO 9227 or ASTM B117 are most widely accepted.

Conclusion: Why ISO 9227 Matters for Fastener Manufacturers

In today’s global fastener market, corrosion resistance is a key indicator of quality and reliability. The ISO 9227 salt spray test allows manufacturers to simulate environmental stress, validate coating performance, and meet international customer requirements.

Implementing ISO 9227 testing not only helps reduce failure risks in corrosive environments but also enhances product competitiveness, especially for exports to Europe and the United States.