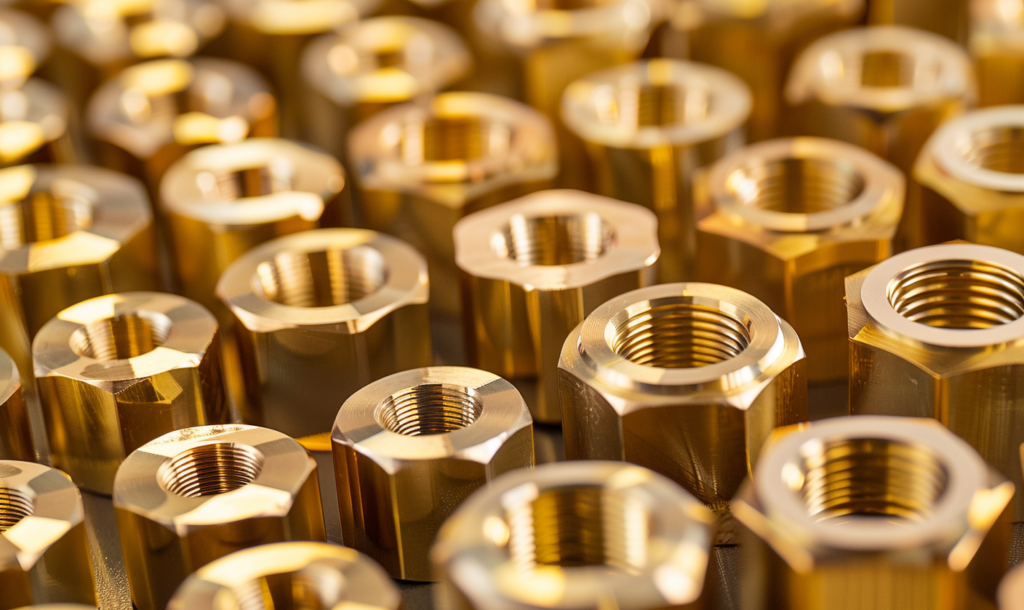

Many importers don’t realize their fasteners could fail EU customs checks—just because they contain restricted substances. Here’s what to watch out for before you ship.

Fastener materials must comply with the RoHS directive by not exceeding limits for substances like lead, mercury, and cadmium. Even tiny amounts can lead to non-compliance and rejected shipments.

RoHS compliance isn’t only about electronic devices anymore. Any component, like a screw or washer in an assembly, must meet strict substance limits. If your fasteners are part of electrical or electronic equipment sold in the EU, they must comply. Here’s what you need to know to stay compliant—and keep your exports moving.

What are the requirements of RoHS?

It’s easy to think RoHS is only for high-tech products. But if your fasteners are used in electronics or electric tools, they’re affected too.

The RoHS directive requires manufacturers and suppliers to ensure products do not contain more than the allowed levels of 10 restricted substances, including heavy metals and flame retardants.

Understanding RoHS compliance thresholds

The directive sets strict thresholds. For most substances, the maximum limit is 0.1% by weight in any homogeneous material. That means even if a tiny layer of coating has excessive lead, the whole part is non-compliant.

| Restricted Substance | Maximum Concentration (by weight) |

|---|---|

| Lead (Pb) | 0.1% |

| Mercury (Hg) | 0.1% |

| Cadmium (Cd) | 0.01% |

| Hexavalent Chromium (Cr6+) | 0.1% |

| PBB (Flame retardant) | 0.1% |

| PBDE (Flame retardant) | 0.1% |

| DEHP, BBP, DBP, DIBP | 0.1% each |

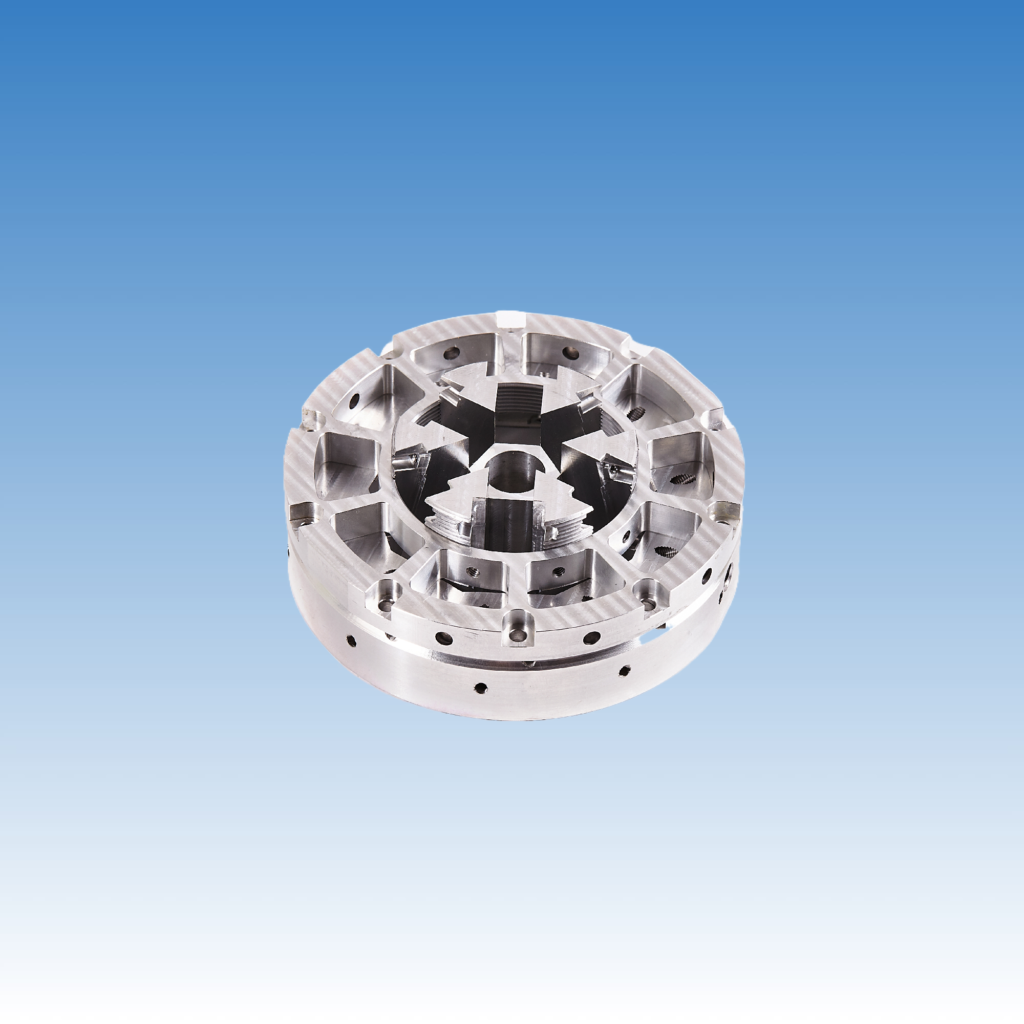

To be RoHS compliant, you must test your fastener material composition—especially coatings. A zinc plating with too much lead or hexavalent chromium can fail. You’ll also need proper documentation like Material Declarations and test reports from certified labs.

What substance restrictions are compliance with the RoHS directive?

Many suppliers assume they only need to worry about “visible” materials, but RoHS applies to every single part.

RoHS restricts 10 specific substances, all known to be hazardous to health and the environment. These include heavy metals and plasticizers commonly used in fastener coatings or packaging.

How these substances impact fasteners

The most relevant restricted substances in fastener production are lead, cadmium, and hexavalent chromium. Here's why:

- Lead is often found in brass or solder used in assemblies. Even trace levels can lead to rejection.

- Cadmium is sometimes used for corrosion resistance but is now heavily restricted.

- Hexavalent chromium can be found in chromate conversion coatings—widely used on bolts and screws.

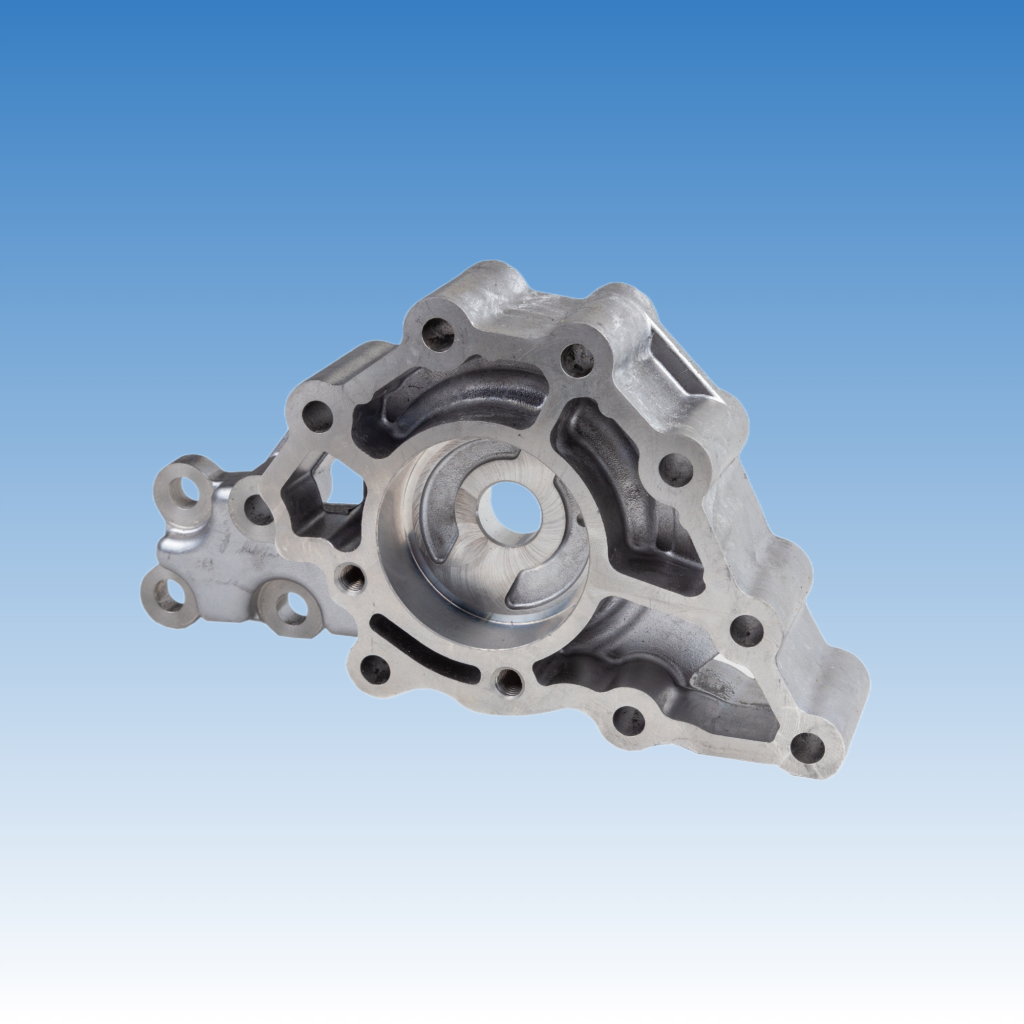

Fasteners made from steel or aluminum alloys may also include trace metals from raw material impurities. Suppliers need to manage their supply chains carefully and require mill certificates or test reports to ensure traceability.

Testing must focus on homogeneous materials—not the whole product. A washer with a zinc-chromate coating must be tested for that coating specifically, not just the entire metal part.

What are the lead requirements for RoHS?

Lead is still one of the most common reasons for RoHS violations. It’s often hidden in metal alloys or coatings.

RoHS limits lead content to 0.1% (1,000 ppm) in any homogeneous material. Fasteners made from brass or zinc alloys must be especially monitored.

Key risks and how to manage them

Brass components often include lead to improve machinability. But unless you’re using a RoHS-compliant low-lead brass alloy (like CW510L), you risk exceeding the limit. Similarly, zinc die castings and some soldered fastener parts might contain lead as a legacy component.

Suppliers need to:

- Ask for a full material composition declaration.

- Use XRF testing for incoming materials.

- Demand lab testing if materials contain brass, bronze, or zinc.

Also, watch for coating services. Sometimes a part is RoHS-compliant until it's plated by a subcontractor who uses old hexavalent chromate processes. A surprise like that at the EU border can ruin a shipment schedule and damage your client relationship.

What products are exempt from RoHS?

Not everything with a fastener must follow RoHS rules—but you must be 100% clear about the product category.

RoHS exemptions apply to certain categories such as military equipment, large industrial tools, and some medical devices, but fasteners in household electronics are almost always covered.

Common exemptions and how to verify them

Some products fall under categories where RoHS doesn't apply, such as:

| Exempted Products | Notes |

|---|---|

| Military equipment | Must be specially designated by end-user |

| Large-scale fixed industrial tools | Must be permanently installed and used in industry |

| Large-scale stationary industrial machines | Size and complexity are key criteria |

| Certain medical devices (until 2021) | Now gradually phased into RoHS |

| Monitoring and control instruments | Some still under phased transition |

However, even exempt products must still follow the general EU REACH regulations. So exemptions aren’t a free pass for toxic substances—they just fall under different timelines or conditions.

If your fasteners are used in mixed-use equipment, you must prove that the final product meets exemption criteria. This often requires clear documentation from the buyer, along with technical product drawings and usage declarations.

Conclusion

RoHS compliance is about more than just electronics—it’s about every material in the chain. Fasteners count, and you can’t afford to overlook them.