Manufacturers often face delays and high costs when producing non-standard fasteners. Using machining centers can solve these problems quickly and efficiently.

Machining centers improve the manufacturing of non-standard fasteners by offering high precision, flexible production, faster lead times, and lower error rates compared to traditional methods.

Manufacturing non-standard fasteners demands accuracy and flexibility. Machining centers offer both. In my experience, when I switched production to machining centers, I immediately noticed a drop in defect rates and delivery times. This technology keeps my customers happy and my operations efficient.

What is the role of machining centers?

Producing unique fasteners requires flexibility, and traditional machines often cannot meet these demands. Machining centers are designed to handle this challenge.

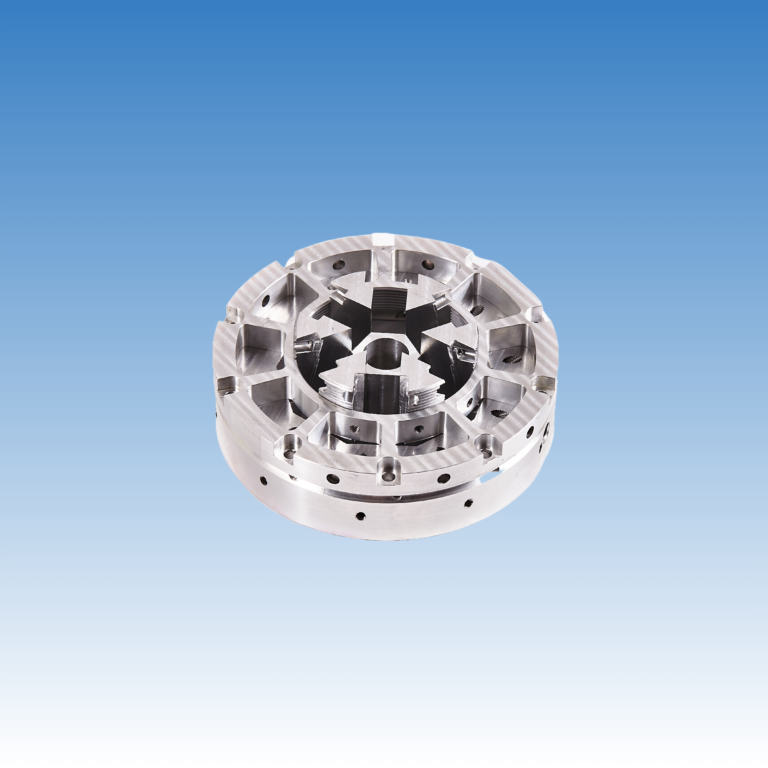

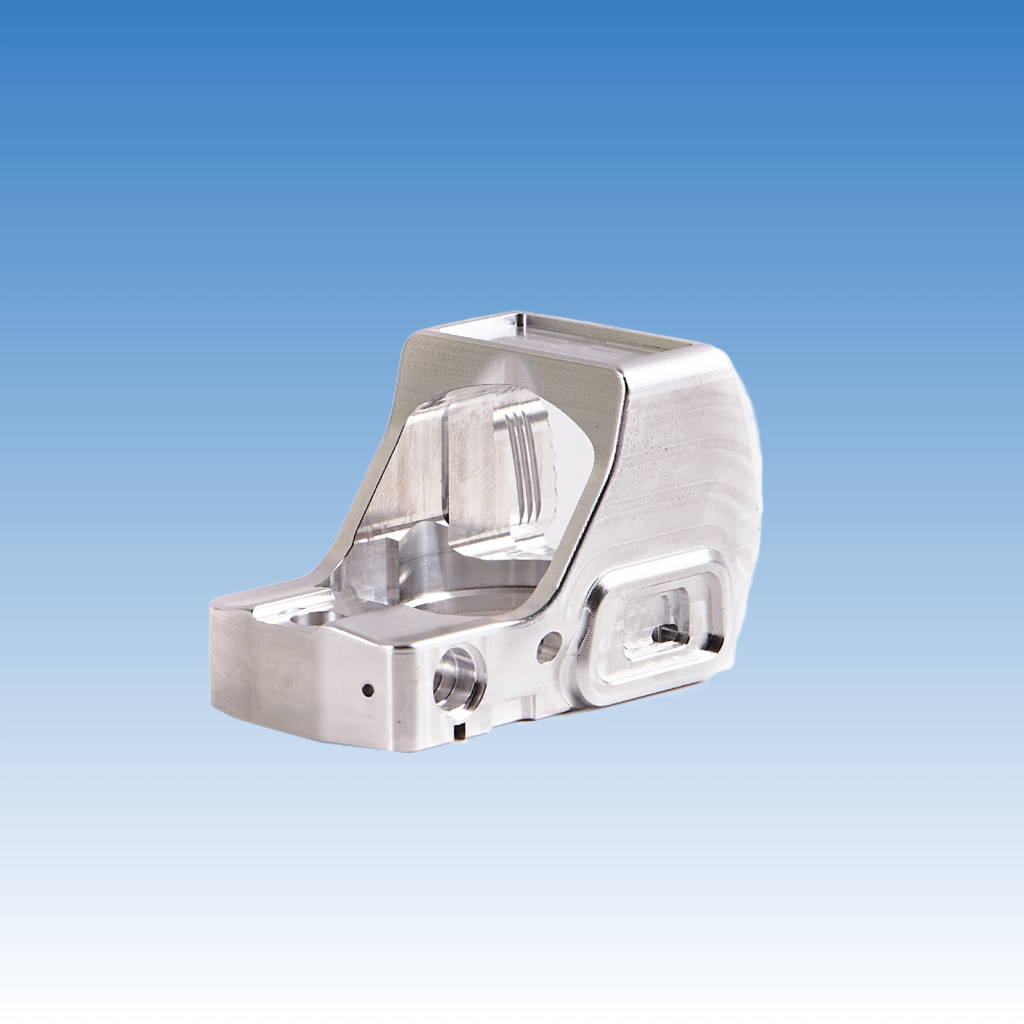

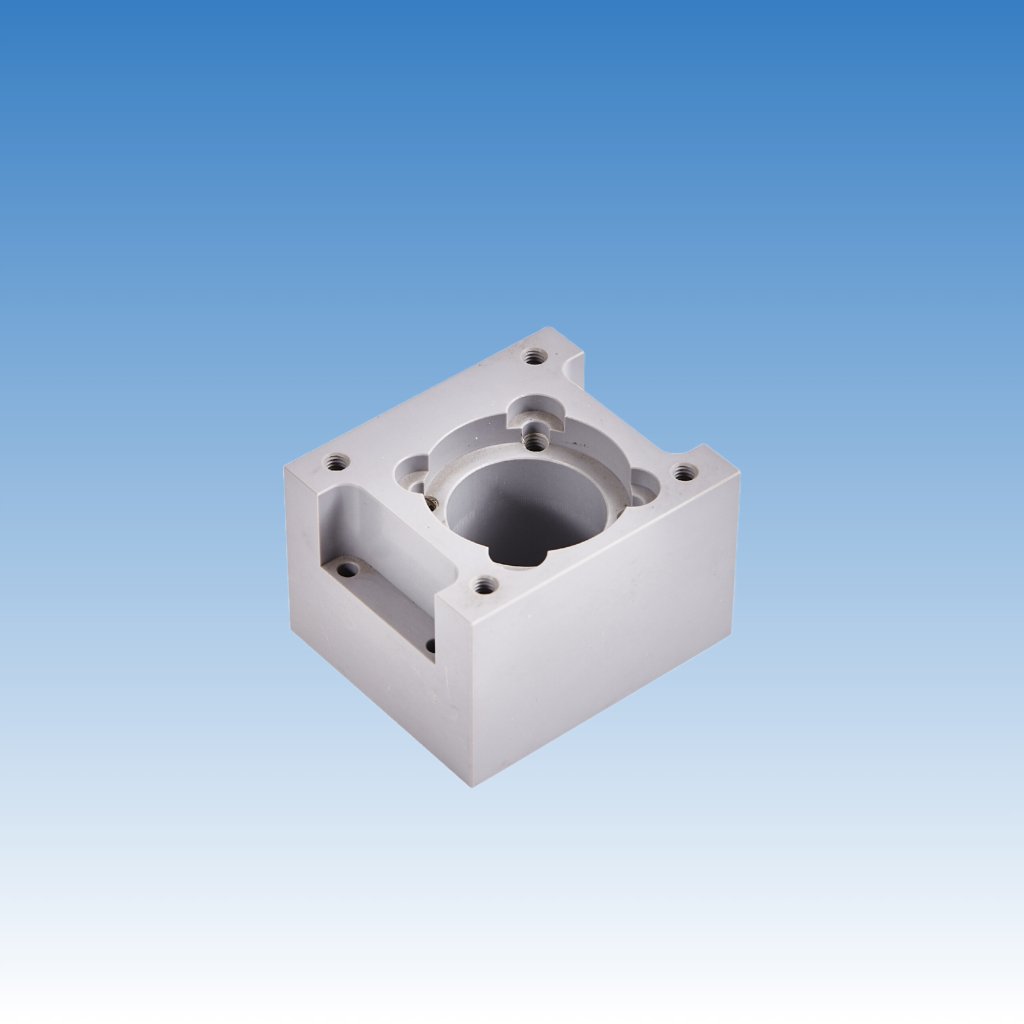

Machining centers perform multiple cutting operations like milling, drilling, and tapping in a single setup, which increases precision and reduces production time for complex parts.

When I first explored machining centers, I realized they were different from any conventional machine I had used before. They combine milling, drilling, and sometimes even turning functions into one setup. This allowed me to cut, drill, and shape non-standard fasteners in one go. Below is a breakdown:

Functions of Machining Centers

| Function | Description |

|---|---|

| Milling | Cutting complex shapes with precision |

| Drilling | Creating precise holes quickly |

| Tapping | Forming threads inside drilled holes |

| Tool changing | Switching tools automatically |

| Measurement | Checking part dimensions in-process |

Machining centers are vital because they reduce human error, minimize setup time, and increase the repeatability of each part produced.

What is the difference between a machining center and a turning center?

Choosing the wrong machine can slow production and increase costs. Knowing the difference between machining centers and turning centers saves time and money.

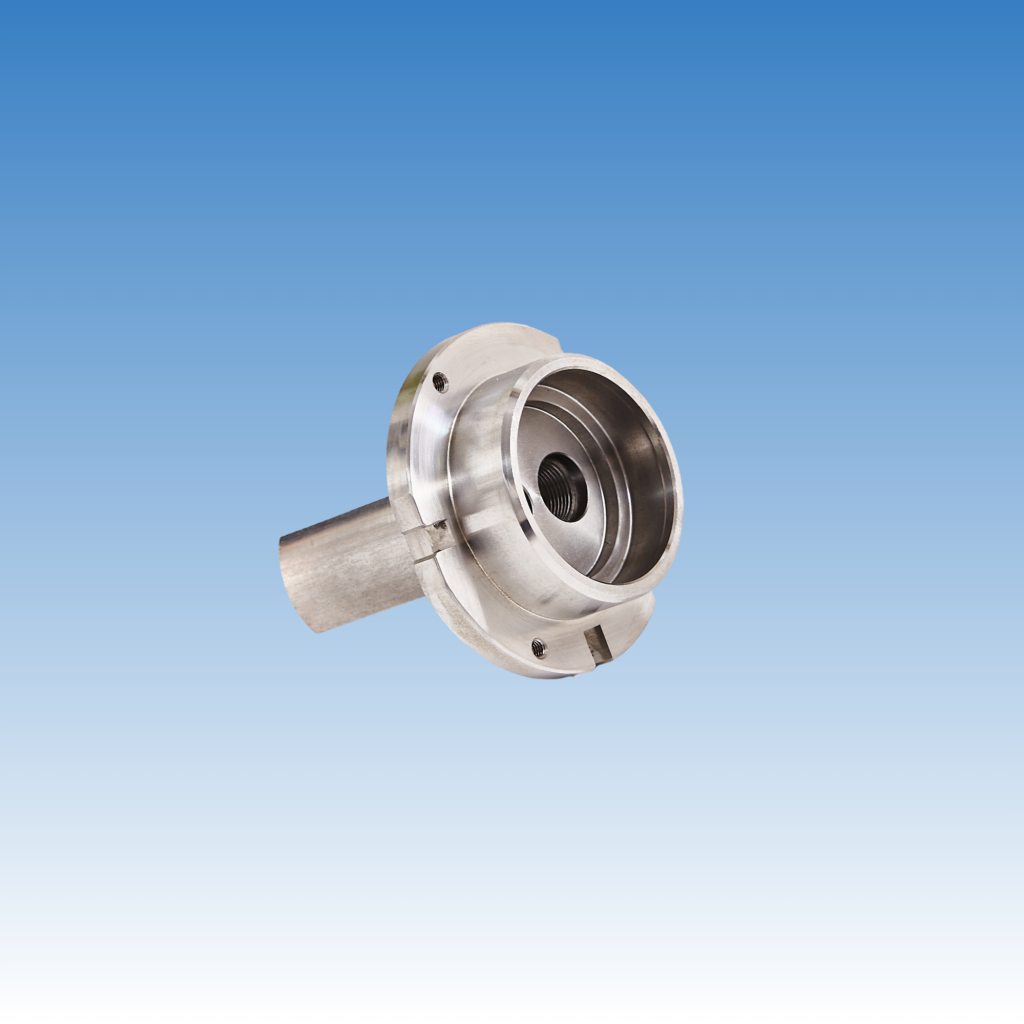

A machining center mainly performs milling operations on a fixed workpiece, while a turning center rotates the workpiece and performs cutting operations like turning and boring.

I made the mistake early on of using a turning center to try to machine complex non-standard fasteners. It was inefficient. After consulting with an expert, I realized turning centers are better suited for cylindrical parts, while machining centers are perfect for irregular shapes. Here is a simple comparison:

Machining Center vs Turning Center

| Feature | Machining Center | Turning Center |

|---|---|---|

| Workpiece motion | Fixed | Rotating |

| Main operations | Milling, drilling, tapping | Turning, boring, threading |

| Ideal parts | Flat, complex geometries | Round, cylindrical shapes |

| Tool movement | Multidirectional | Usually linear and radial |

Understanding this difference helped me better plan my production lines and select the right machine for the right job.

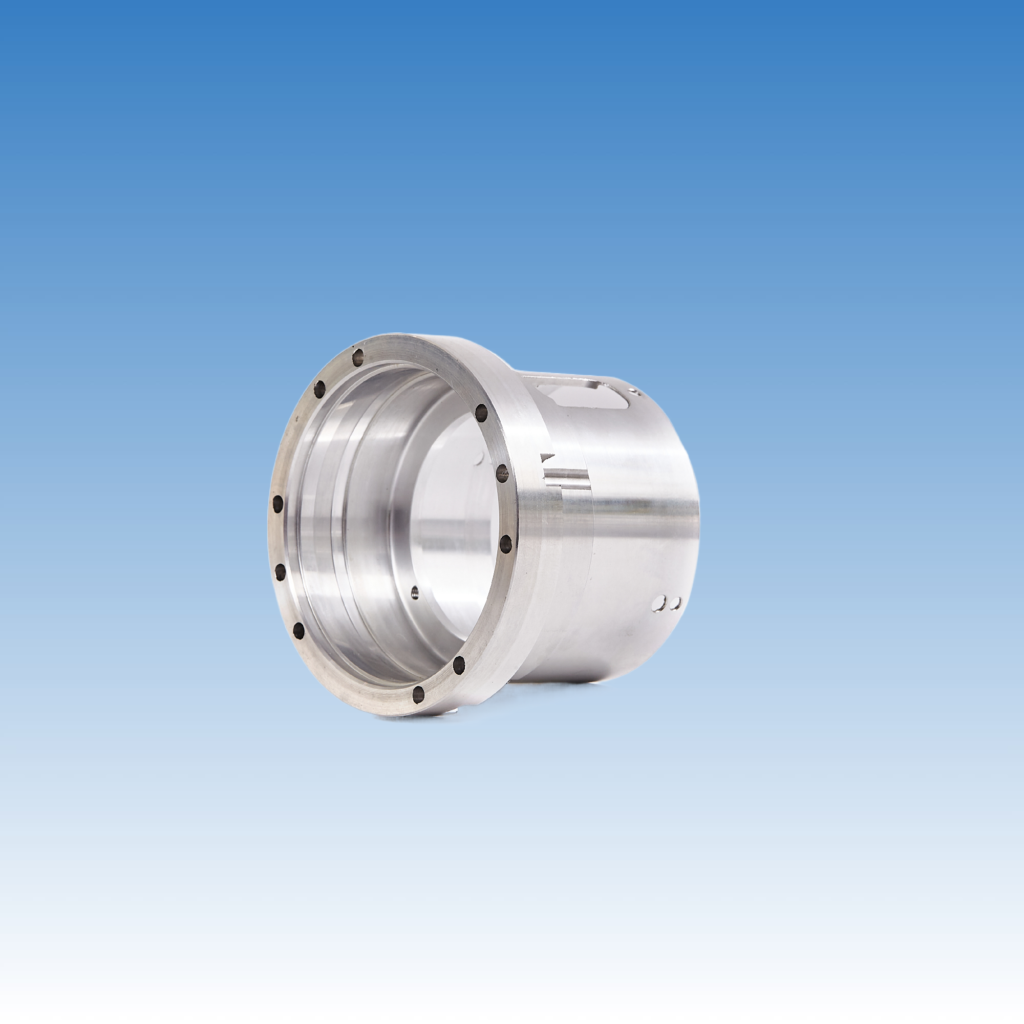

What are the components of a machining center?

Machining centers seem complex at first, but understanding their main parts makes them easier to operate and maintain.

Key components of a machining center include the spindle, tool changer, worktable, control system, and coolant system, all of which work together to automate precision machining tasks.

When I bought my first machining center, I spent hours studying its parts to make sure my team could operate and maintain it properly. Here’s a quick guide to the main components:

Main Components of a Machining Center

| Component | Function |

|---|---|

| Spindle | Rotates the cutting tool |

| Automatic Tool Changer (ATC) | Switches tools without manual help |

| Worktable | Holds and positions the part |

| Control System | Inputs and executes machining commands |

| Coolant System | Keeps the tool and workpiece cool |

Every component plays a vital role. For example, a faulty spindle can cause inaccuracies, while a slow tool changer can waste production time. Keeping all these components in top condition is key to running a smooth operation.

What are the disadvantages of CNC machining?

While CNC machining is powerful, it is not perfect. Knowing its downsides can help businesses plan better.

CNC machining disadvantages include high initial costs, expensive maintenance, operator training needs, and material waste for simple parts compared to other processes like casting.

I learned these disadvantages the hard way. The initial investment was much higher than I expected, and training staff to properly program and maintain the machines took months. Here's a table that sums up the main issues:

Disadvantages of CNC Machining

| Disadvantage | Explanation |

|---|---|

| High Setup Costs | Machines and software are expensive |

| Training Requirement | Skilled operators are needed |

| Maintenance Costs | Repairs and maintenance are costly |

| Material Waste | High for simple parts |

Despite these challenges, the quality, flexibility, and speed of CNC machining make it a worthy investment for producing non-standard fasteners and other complex parts.

Conclusion

Machining centers offer precision, flexibility, and speed in manufacturing non-standard fasteners, despite their initial investment and maintenance costs.