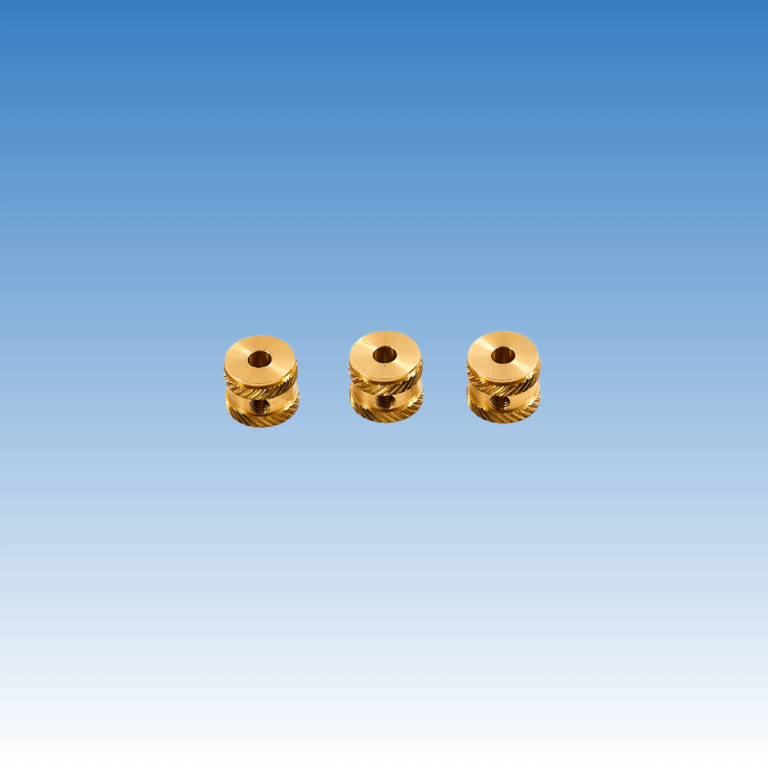

Small fastener production is tricky: high precision, small size, large volumes. Without the right machines, quality and speed suffer. How do we fix this?

Swiss-type machines boost efficiency in small fastener manufacturing by offering high precision, quick cycle times, and the ability to run multiple operations in a single setup.

When I first started sourcing parts for clients, I realized how critical it was to match the machine to the part. Swiss machines were the game changer. They turned long, slow jobs into fast, repeatable, high-quality runs. Let me explain why they matter so much.

Why is it called a Swiss machine?

Manufacturers needed a solution for making the tiniest, most precise parts—especially for watches. Switzerland, the home of fine watchmaking, was the birthplace of this solution.

A Swiss machine gets its name because it was invented in Switzerland during the late 19th century for making precision watch parts.

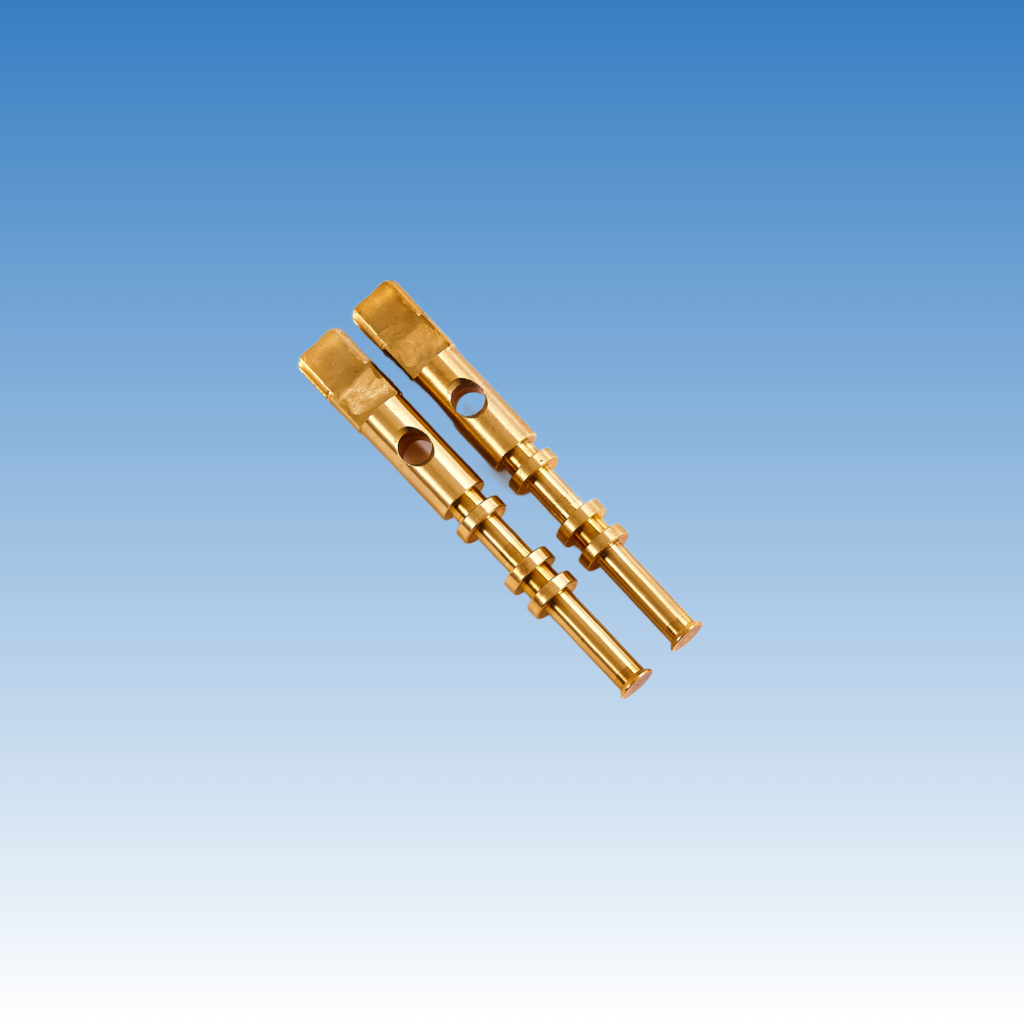

The story of Swiss-type machines starts with watchmakers. They needed something better than standard lathes. The sliding headstock design was the answer. The material stays close to the cutting tool at all times. This made parts stronger, straighter, and much more accurate. I still remember visiting a supplier and watching tiny parts being turned out with almost no visible error. It was impressive.

Key Feature: Sliding Headstock vs. Fixed Headstock

| Feature | Sliding Headstock (Swiss) | Fixed Headstock (Traditional CNC) |

|---|---|---|

| Material Movement | Moves through the guide bushing | Stays stationary |

| Best for | Small, long parts | Larger, heavier parts |

| Typical Tolerances | Tighter, more precise | Standard industrial tolerances |

| Vibration | Very low | Moderate |

What are the advantages of a Swiss lathe?

In mass production, even a few seconds matter. Swiss lathes are built for speed and precision, which adds up fast across thousands of parts.

Swiss lathes offer advantages like tighter tolerances, faster cycle times, less material waste, and multi-operation capability in a single setup.

When I first sourced Swiss parts, what struck me was not just the accuracy, but the efficiency. A part that took 10 minutes on a standard lathe took 3 minutes on a Swiss lathe. Plus, it needed almost no post-machining. These machines combine milling, drilling, and turning at the same time, saving huge amounts of labor and machine time.

Major Advantages in Detail

| Advantage | Description |

|---|---|

| Precision | Achieve tolerances as tight as ±0.0002 inches |

| Speed | Multiple operations performed simultaneously |

| Material Support | Reduces deflection on slender parts |

| Tool Changes | Automatic and fast; minimizes downtime |

| Cost Saving | Less secondary operations needed |

What is the difference between Swiss machining and CNC machining?

Both Swiss machining and CNC machining produce precise parts. However, the way they hold and work on the material is very different.

Swiss machining uses a sliding headstock and guide bushing for continuous support, while traditional CNC machining holds the material stationary during cutting.

I remember a client asking me why the Swiss parts were more expensive at first glance. After a quick explanation, he realized Swiss parts needed fewer inspections and touch-ups. They actually lowered his total costs. Swiss machining keeps the bar stock moving steadily through a guide bushing. CNC machining clamps it at one or two points. For tiny, long parts like screws or shafts, steady support is crucial. Swiss is simply better for these jobs.

Side-by-Side Comparison

| Feature | Swiss Machining | CNC Machining |

|---|---|---|

| Material Support | Through guide bushing | Clamped at ends |

| Best for | Long, slender parts | Wide range of parts |

| Number of Setups | One (multi-tasking) | Often multiple setups |

| Accuracy and Finish | Extremely high | High, but less consistent |

What is the tolerance of a Swiss lathe?

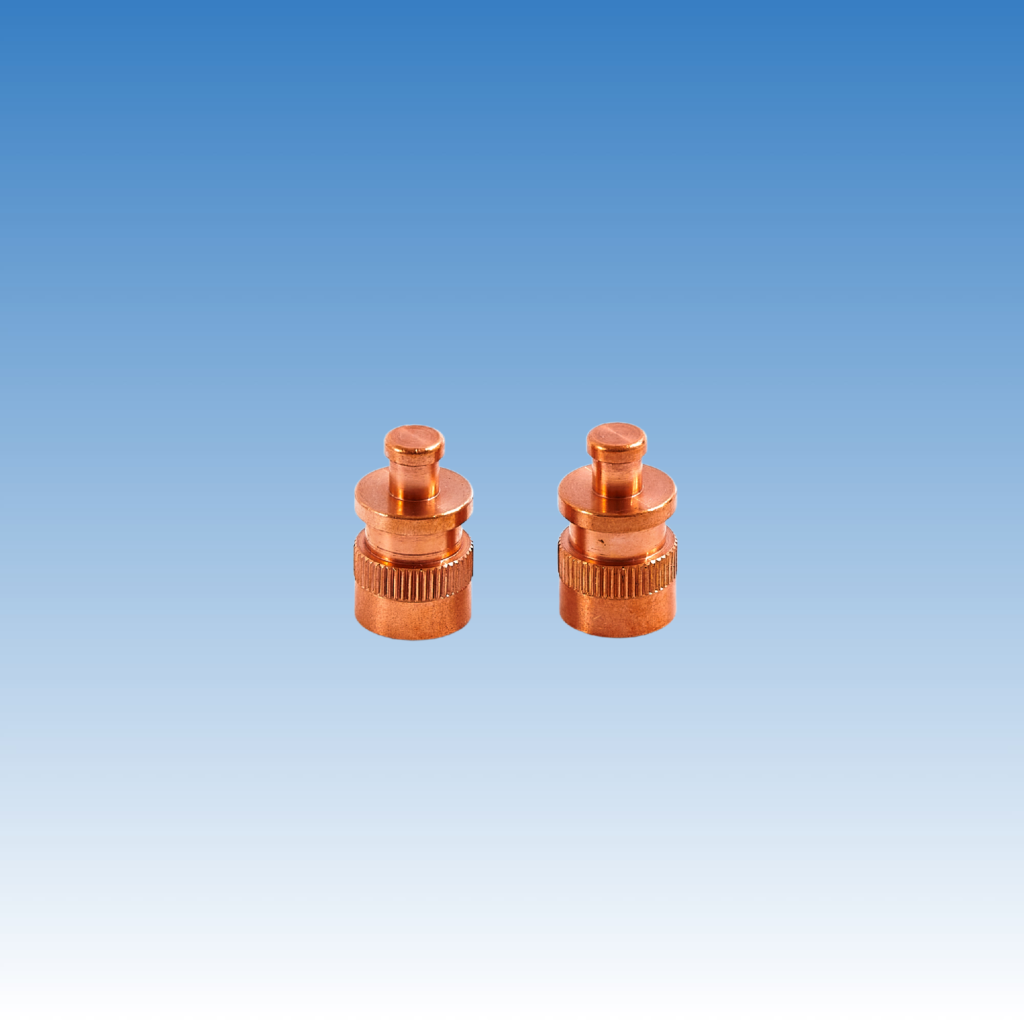

Tolerances define whether a part fits right or fails. In industries like automotive and medical, there’s no room for mistakes.

Swiss lathes commonly achieve tolerances as tight as ±0.0002 inches (5 microns), making them ideal for high-precision applications.

Tight tolerances are one big reason why I often recommend Swiss machining for turned parts. I remember a project involving medical pins where ±0.0003 inches wasn’t enough. Only a Swiss-type machine could meet the spec without huge rejection rates. Most Swiss lathes maintain extremely close tolerances due to the way the material is always supported right near the cutting tool. The steady cutting action means fewer dimensional errors and smoother surface finishes.

Typical Tolerance Ranges

| Part Type | Typical Tolerance (Inches) | Application Examples |

|---|---|---|

| Medical Fasteners | ±0.0001–0.0002 | Surgical tools, implants |

| Automotive Components | ±0.0002–0.0005 | Fuel injectors, sensor housings |

| Electronics Connectors | ±0.0002–0.0004 | Mobile devices, wearables |

Conclusion

Swiss-type machines are the backbone of efficient, precise, small fastener manufacturing, offering a perfect mix of speed, quality, and reliability.