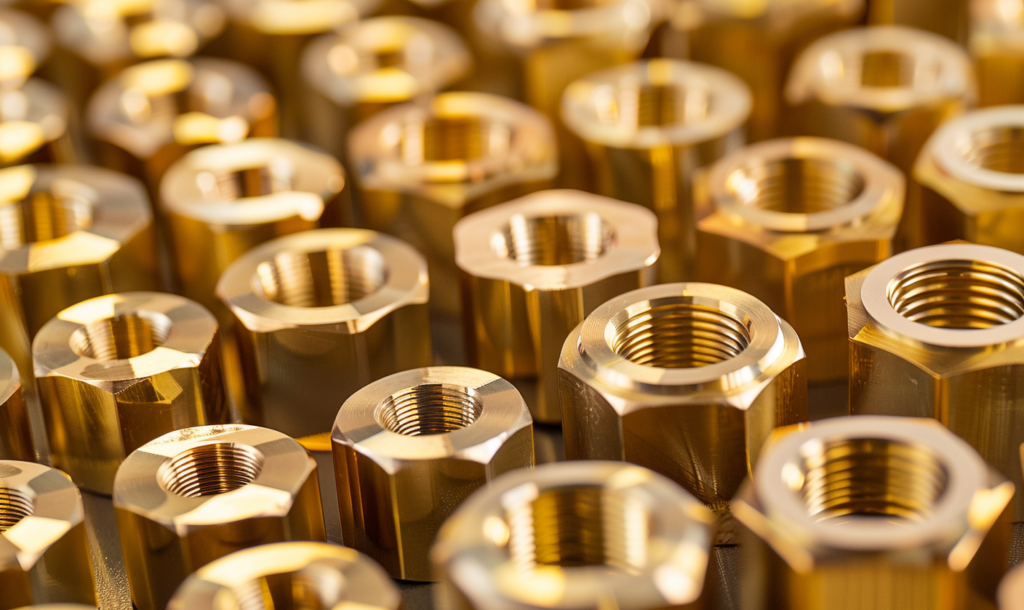

Fasteners face corrosion, wear, and environmental damage—but surface treatments can extend their life and reliability.

Common surface treatments for fasteners include zinc plating, hot-dip galvanizing, black oxide, phosphating, and mechanical plating, each offering varying levels of corrosion resistance, cost, and application suitability.

Surface treatments are essential for fasteners used in harsh environments. They enhance durability, prevent rust, and improve performance. Choosing the right treatment depends on the specific application and environmental conditions.

What is the most common type of fastener plating?

Zinc plating is the most widely used due to its cost-effectiveness and adequate corrosion resistance.

Zinc plating provides a sacrificial layer that corrodes before the underlying metal, extending the fastener's lifespan, especially in indoor or mildly corrosive environments.

Understanding Zinc Plating

Zinc plating involves electroplating a thin layer of zinc onto the fastener's surface. This layer acts as a barrier against moisture and oxygen, which are primary contributors to corrosion. The process is economical and provides a bright, clean finish, making it suitable for aesthetic applications as well.

However, zinc plating is not ideal for highly corrosive environments, such as marine settings, as the thin layer can wear off over time. In such cases, thicker coatings like hot-dip galvanizing are preferred.

| Plating Type | Corrosion Resistance | Cost | Appearance | Application Suitability |

|---|---|---|---|---|

| Zinc Plating | Moderate | Low | Bright, shiny | Indoor, low-corrosion areas |

| Hot-Dip Galvanizing | High | Medium | Dull, matte | Outdoor, high-corrosion areas |

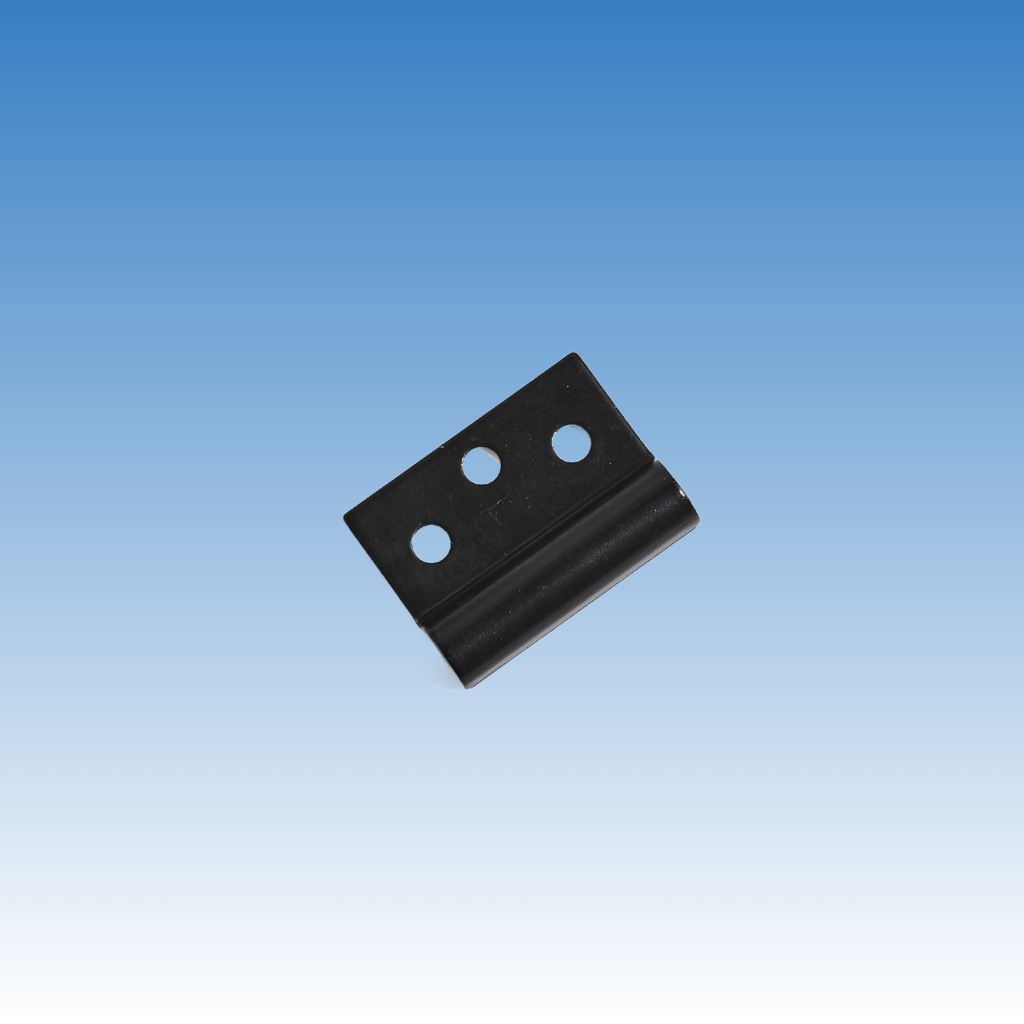

| Black Oxide | Low | Low | Black, matte | Decorative, indoor use |

| Phosphating | Moderate | Low | Gray, matte | Primer for painting |

| Mechanical Plating | High | Medium | Uniform, matte | High-strength fasteners |

What is the difference between coating and finishing?

Coating involves applying a protective layer, while finishing refers to the final surface condition, including texture and appearance.

Coating adds a material layer to protect against corrosion or wear, whereas finishing encompasses processes that alter the surface's texture, appearance, or dimensions without necessarily adding material.

Delving into Coating and Finishing

Coatings are applied to fasteners to enhance properties like corrosion resistance, electrical conductivity, or lubricity. Common coatings include zinc, nickel, and epoxy. These layers are typically added through processes like electroplating, dipping, or spraying.

Finishing processes, on the other hand, modify the fastener's surface without necessarily adding a new material layer. Techniques like polishing, grinding, or blasting are used to achieve desired surface textures or remove imperfections. Finishing can also prepare the surface for subsequent coatings or improve aesthetics.

Understanding the distinction is crucial for selecting the appropriate treatment based on functional requirements and environmental conditions.

| Process Type | Purpose | Methods Involved | Material Added |

|---|---|---|---|

| Coating | Protection, enhanced properties | Electroplating, dipping, spraying | Yes |

| Finishing | Surface texture, aesthetics | Polishing, grinding, blasting | No |

What is the surface finish for fasteners?

Surface finish refers to the texture and appearance of a fastener's surface, affecting its performance and suitability for specific applications.

Surface finishes range from smooth, polished surfaces to rough, matte textures, influencing factors like friction, appearance, and coating adhesion.

Exploring Surface Finishes

The surface finish of a fastener impacts its mechanical performance and compatibility with coatings or adhesives. A smoother finish can reduce friction during installation, while a rougher texture may enhance paint or adhesive bonding.

Common surface finishes include:

- Polished: Achieved through buffing or grinding, providing a shiny appearance and reduced friction.

- Matte: Resulting from blasting or chemical treatments, offering better paint adhesion.

- Textured: Created via knurling or etching, improving grip or aesthetic appeal.

Selecting the appropriate surface finish depends on the fastener's intended use, required performance characteristics, and environmental exposure.

| Finish Type | Characteristics | Applications |

|---|---|---|

| Polished | Smooth, shiny | Decorative, low-friction assemblies |

| Matte | Dull, non-reflective | Paint adhesion, reduced glare |

| Textured | Patterned, rough | Improved grip, aesthetic design |

What is salt spray test for fasteners?

The salt spray test evaluates a fastener's corrosion resistance by exposing it to a saline mist environment.

This accelerated corrosion test simulates harsh conditions to assess how well a fastener's coating protects against rust over time.

Understanding Salt Spray Testing

In a salt spray test, fasteners are placed in a chamber where they are continuously exposed to a fine mist of saltwater solution, typically 5% sodium chloride, at a controlled temperature. The duration of exposure varies based on the desired corrosion resistance standards.

The test aims to replicate the corrosive effects of marine or industrial environments in a shorter timeframe. Results are measured by the time taken for visible corrosion, such as rust or pitting, to appear on the fastener's surface.

While the salt spray test provides valuable insights into a coating's protective capabilities, it's essential to note that it doesn't perfectly predict real-world performance, as actual conditions may involve varying temperatures, humidity, and mechanical stresses.

| Test Parameter | Typical Value |

|---|---|

| Salt Concentration | 5% NaCl solution |

| Temperature | 35°C (95°F) |

| Duration | 24 to 1,000+ hours |

| Evaluation Criteria | Time to first corrosion |

Conclusion

Selecting the appropriate surface treatment for fasteners is crucial for ensuring their performance, longevity, and suitability for specific applications and environments.