When non-standard parts wobble during assembly or fail in performance, poor concentricity is often the hidden cause.

To ensure concentricity in non-standard parts machining, you need precise fixturing, proper CNC programming, and reliable measurement with CMM or dial indicators.

If you've ever dealt with unexpected vibrations, assembly interference, or bearing failures, chances are concentricity was the problem. I’ve seen customers reject parts that looked perfect—until they rotated. Let’s look at how we can fix that from the ground up.

What is the ISO standard for concentricity?

Most buyers assume “round” means “precise,” but the standard defines it very specifically.

ISO 1101 defines concentricity as a geometric tolerance that controls the median points of all diameters to be centered around a common axis.

Under ISO 1101, concentricity is a positional tolerance. It ensures that all circular features of a part share the same center axis. Unlike runout, which measures the surface directly, concentricity targets the internal geometry—making it harder to inspect but more powerful for high-precision applications.

When a client requests concentricity, I always confirm they truly need it. Most of the time, runout control is enough and easier to measure. But in aerospace or medical parts, true concentricity becomes critical.

| Term | Defined By | Description |

|---|---|---|

| Concentricity | ISO 1101 | Median axis of circular elements aligned |

| Runout | ISO 1101 | Surface variation during rotation |

| True Position | ISO 5458 | 3D location tolerance |

How to measure concentricity using CMM?

You can’t fix what you can’t measure. That’s why inspection must be built into your workflow.

To measure concentricity using a CMM, probe points along circular features and analyze the median axis against a defined datum axis using geometric tolerance functions.

CMMs (Coordinate Measuring Machines) allow for high-resolution measurement of internal geometry. The process starts by defining a primary axis (often the center of the main bore or shaft). Then, multiple points are collected from the feature in question—usually an outer ring or secondary hole.

The software calculates the median line of the sampled points and compares it to the reference axis. If the deviation is within the specified tolerance, the part passes.

Here’s what we usually check:

- Define the reference (datum) axis.

- Probe at least 8–12 points along the circular feature.

- Use the software to compute median axis and distance to datum.

- Review the result visually and in report form.

| Step | Description |

|---|---|

| 1. Datum Set | Establish central axis as reference |

| 2. Probe Points | Sample on feature circumference |

| 3. Calculation | Median axis is compared to datum |

| 4. Result | Numeric + graphic pass/fail output |

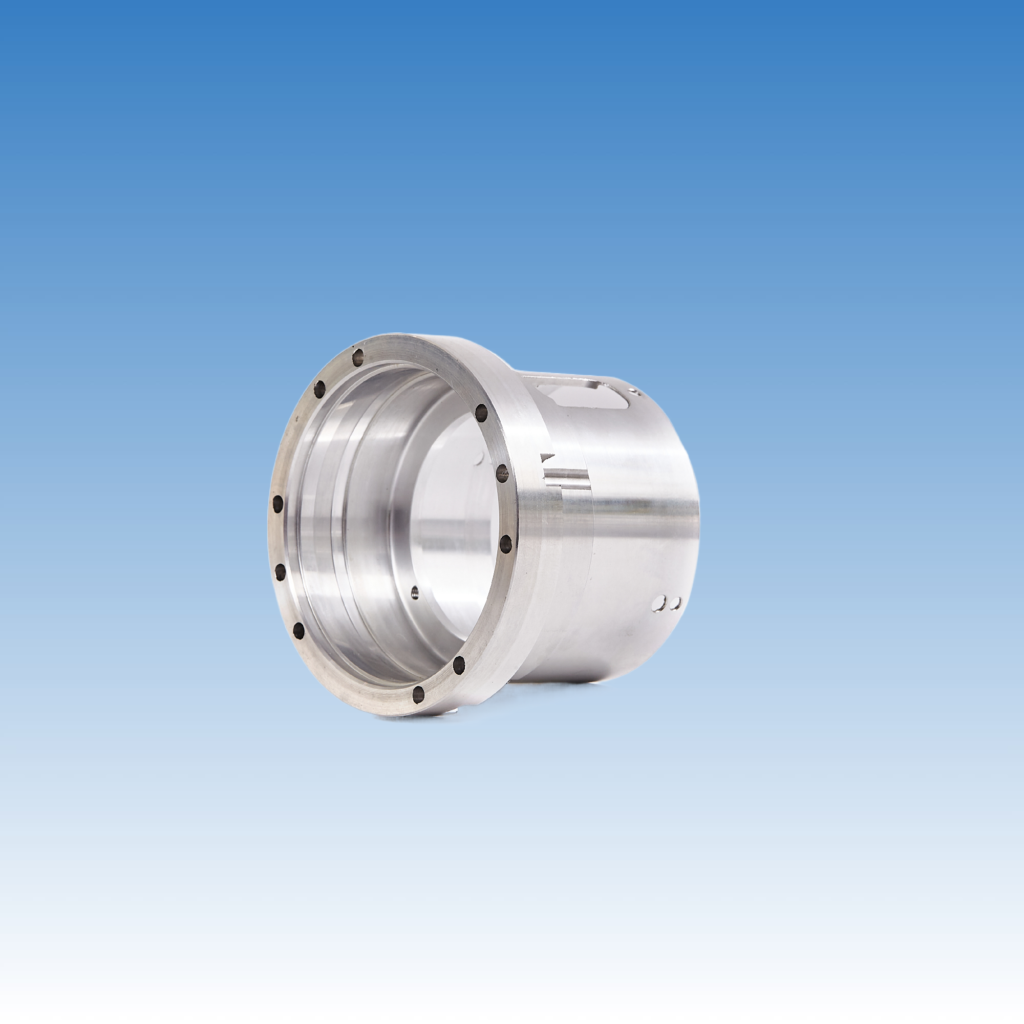

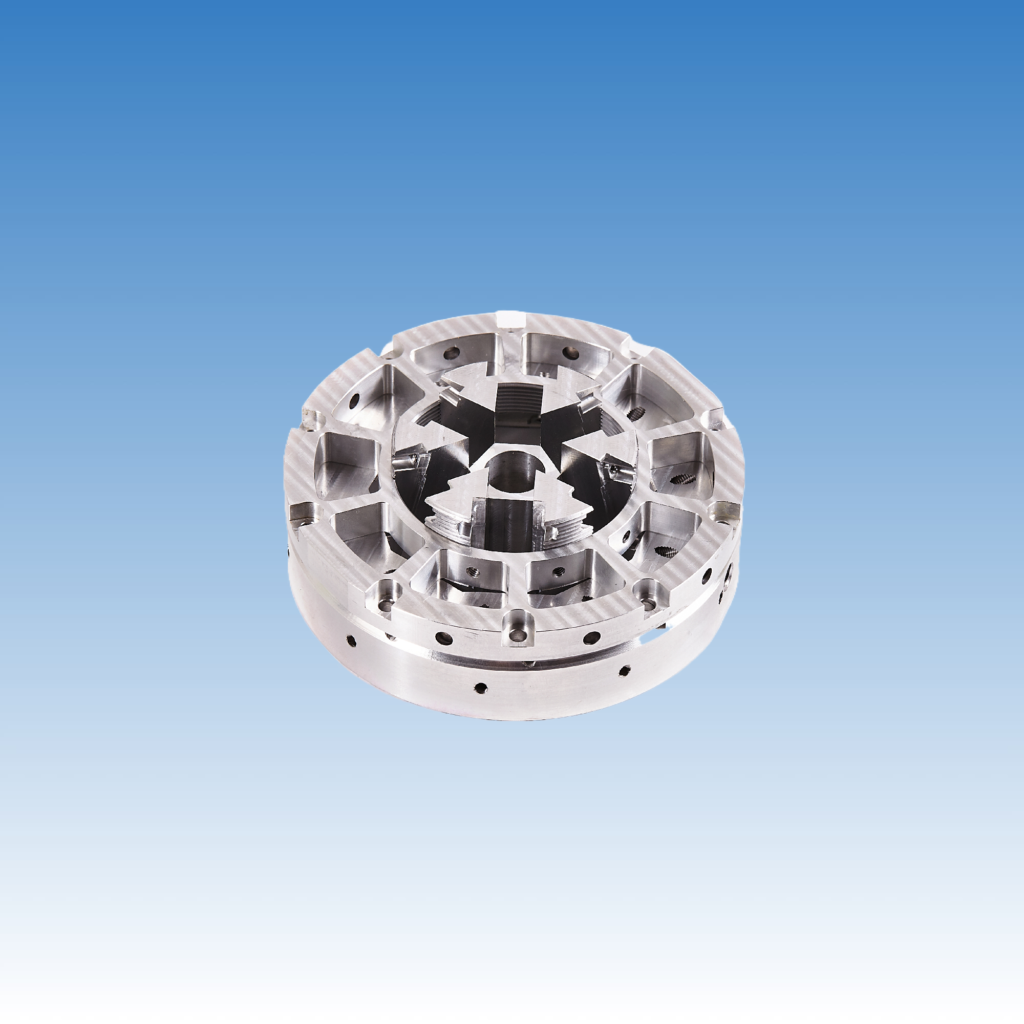

In our workshop, we use ZEISS and HEXAGON CMMs with this process. For critical parts like connectors or motor housings, we run this check 100%.

Does concentricity affect accuracy?

Many customers ask if poor concentricity is a big deal. The short answer: it can destroy performance.

Yes, concentricity directly affects accuracy in assembly, rotation, and dynamic performance—especially in high-speed or tolerance-sensitive parts.

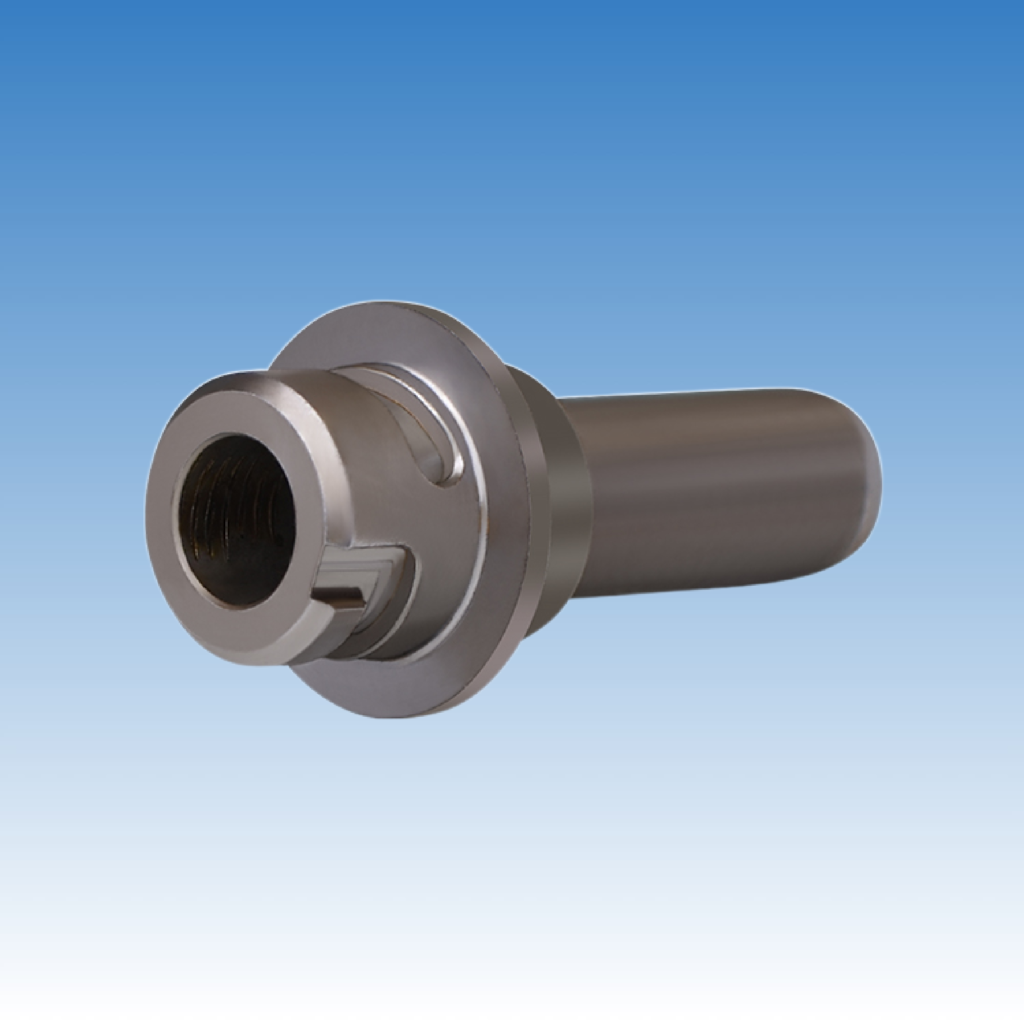

Imagine a motor shaft that’s slightly off-center. That imbalance turns into vibration, uneven wear, and even overheating. If a bearing hole is off-center, the shaft won’t sit correctly. In medical or aerospace parts, even a 0.01mm offset can lead to total system failure.

In my experience, buyers sourcing from low-cost regions often ignore concentricity until they see the parts run. Then the complaints begin—noise, looseness, thermal issues. We now include concentricity reviews in our pre-production checks for custom shafts, housings, and couplings.

Here are areas where concentricity matters most:

| Application | Effect of Poor Concentricity |

|---|---|

| Rotating shafts | Vibration, bearing wear |

| Bearing housings | Misalignment, failure |

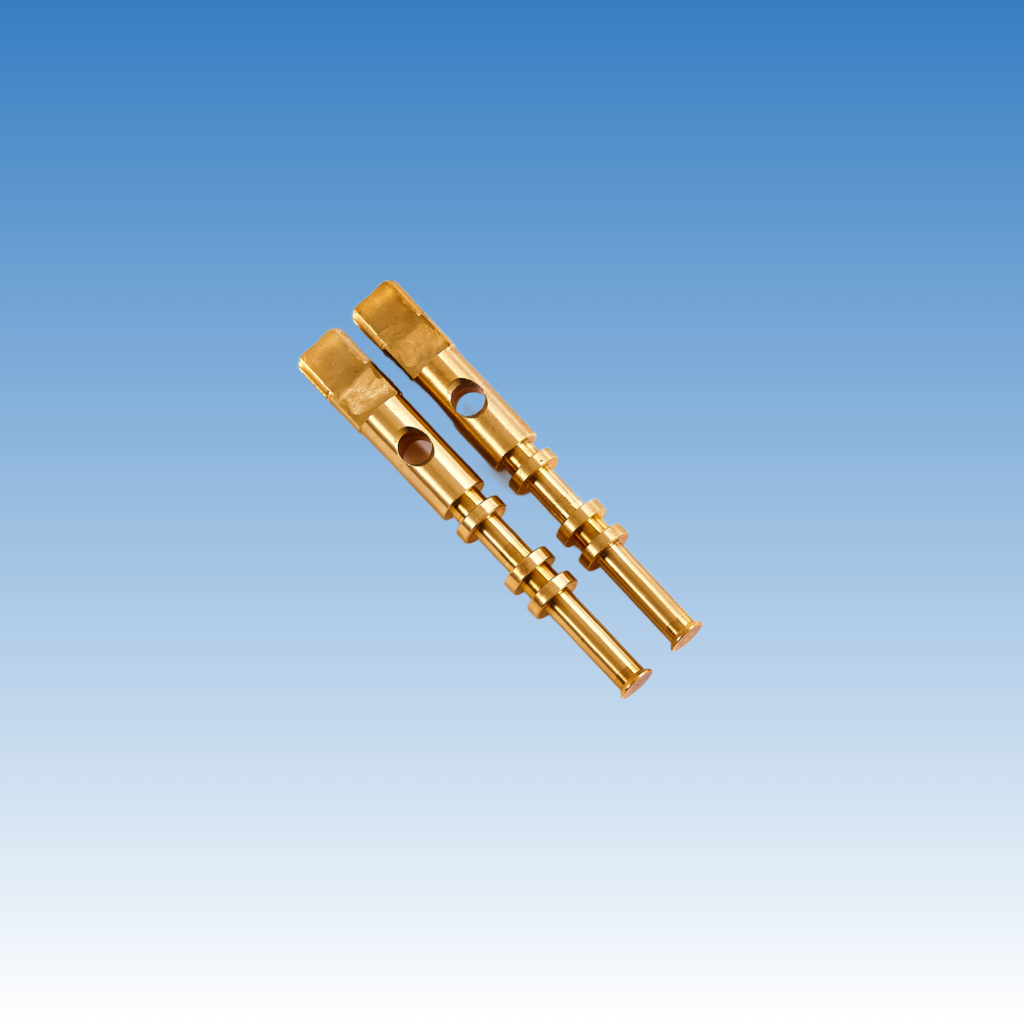

| Connectors | Loose fit, contact loss |

| Gears | Noise, uneven loading |

Ensuring concentricity early saves cost downstream. It’s better to check upfront than replace a whole machine later.

How do you measure concentricity?

Many buyers confuse concentricity with runout. But they are not the same—and not measured the same way.

You measure concentricity using CMMs for median axis alignment or dial indicators for simpler runout-based checks. True concentricity must compare internal geometry.

There are two levels of checking:

- Basic runout test with a dial indicator: Place the part on V-blocks or a spindle. Rotate and watch the needle. This shows surface variation but not true concentricity.

- True concentricity measurement using CMM: As explained earlier, probe and compute the axis from internal features.

I once worked with a client who insisted his parts passed runout checks. But when we did a concentricity test, the internal bore was 0.03mm off-axis—just enough to jam in the final assembly. We had to remake the batch.

| Method | Equipment | Measures | Use Case |

|---|---|---|---|

| Dial Indicator | Manual tool | Surface variation | Quick checks, non-critical parts |

| CMM | Computer-based | Median axis vs. datum | Precision parts, QC reports |

| Optical System | Laser/machine vision | 3D alignment | Advanced, automated lines |

Always match the measurement method to your part’s function. If it rotates or aligns, invest in accurate checks.

Conclusion

To ensure concentricity in non-standard parts, you must combine proper machining setups, ISO-based measurement, and precise CMM inspection techniques.