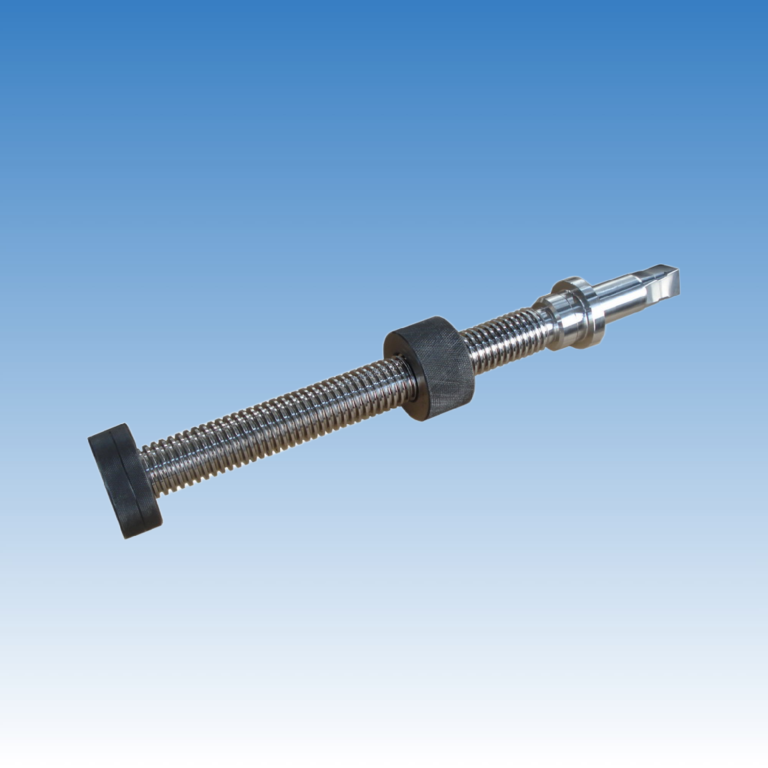

Long shaft-type fasteners seem simple, but machining them accurately is full of traps—taper, bending, vibration, and unstable surface finish are common problems.

To machine long shaft-type non-standard fasteners, we must use Swiss-type lathes, steady rests, tailstocks, or custom fixtures to keep the shaft stable, reduce vibration, and control tolerance.

Long fasteners like motor shafts are widely used, especially in industries like automotive, electronics, and energy. But their machining process is complex because they are long and thin. They are hard to hold steady during cutting. Even a little vibration will ruin the tolerance. So, I always tell my clients—if you're sourcing long shafts, don't just ask the supplier “can you do it?” Ask “how do you control straightness, vibration, and tolerance during cutting?” That tells you if they really understand the process.

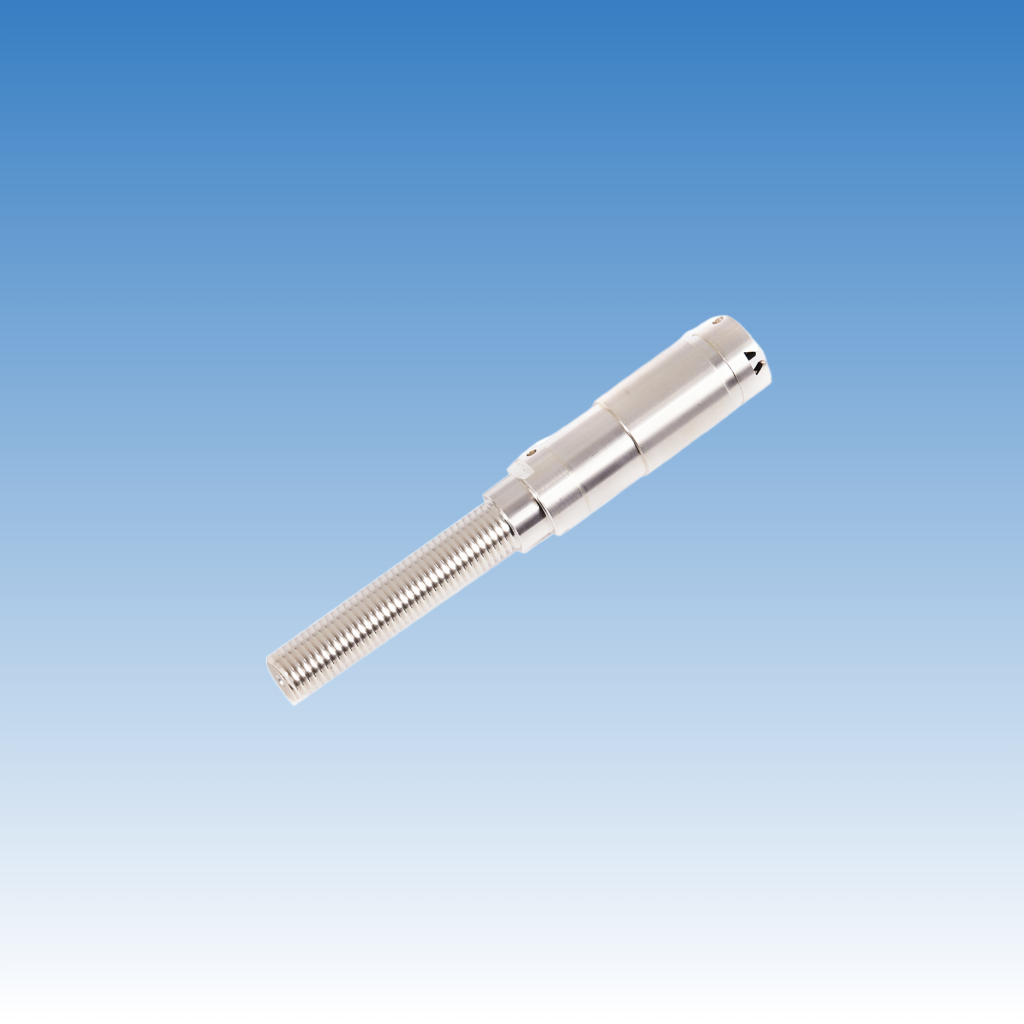

How are motor shafts made?

Motor shafts look simple but are actually tricky to make. Without good control, they bend easily and don’t fit properly in motors.

Motor shafts are usually machined using centerless grinding, Swiss-type turning, and sometimes even precision rolling, depending on the tolerance and material.

Motor shafts are usually long, thin, and precise. This makes them hard to machine. For example, some shafts have a length-to-diameter ratio above 10:1. That means vibration is a big problem during turning. To fix this, we use Swiss-type machines. These machines support the shaft close to the cutting point. That keeps it stable. Sometimes we also use a steady rest or tailstock. In my past projects, I had to help a client rework 5,000 pieces because the original supplier didn’t use a steady rest. The result? Bending and unacceptable runout. After switching to Swiss-type with double support, problem solved.

Here’s a quick comparison of methods:

| Process | Use Case | Pros | Cons |

|---|---|---|---|

| Swiss-type turning | Long, thin, precision shafts | High precision, less bending | High machine cost |

| Centerless grinding | Finish and diameter control | Good surface finish | Needs round parts |

| CNC turning | Shorter shafts or thick diameters | Flexible, cost-effective | Poor for long slender parts |

| Precision rolling | Mass production, specific shapes | Fast, consistent | High tooling cost |

So when a customer tells me they need motor shafts with H6 tolerance and a 150mm length, I know Swiss-type turning + centerless grinding is the best combo. It may cost more, but it's stable.

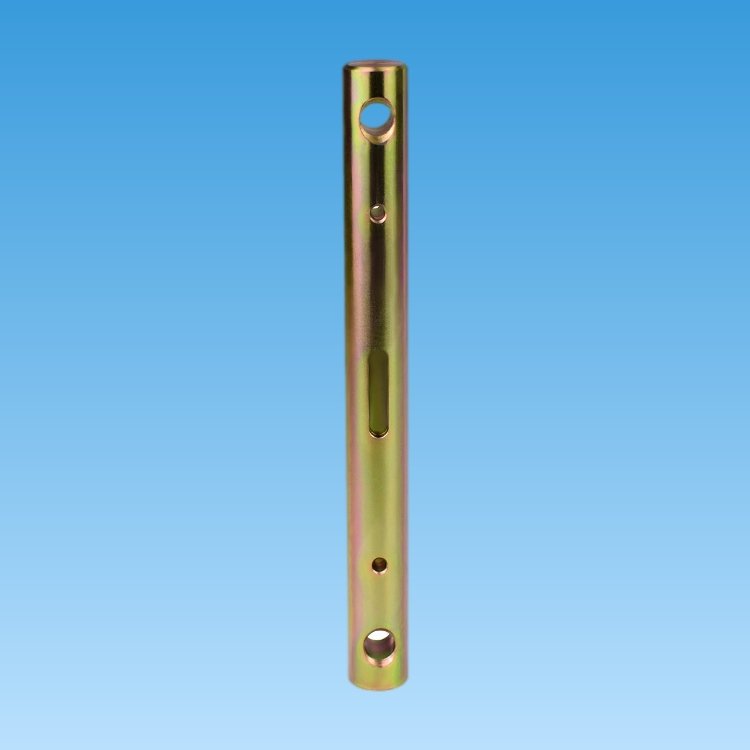

How many types of shafts are there?

Different machines need different types of shafts. Knowing these types helps you choose the right machining process.

The most common shaft types are transmission shafts, machine shafts, axle shafts, and special-purpose shafts like motor shafts and lead screws.

Understanding shaft types helps buyers talk more clearly with suppliers. Here’s a simple breakdown:

| Shaft Type | Function | Common Example |

|---|---|---|

| Transmission Shaft | Transfers torque | Gear shafts |

| Machine Shaft | Part of a machine itself | Crankshafts |

| Axle Shaft | Supports load and allows rotation | Car axles |

| Spindle Shaft | High-speed rotating shaft | CNC spindles |

| Special Shafts | Custom shapes/functions | Electric motor shafts |

Each type has a different structure. Transmission shafts often need high torque and straightness. Machine shafts might need complex steps and tight tolerance. Special shafts may have threads, keyways, or even knurling. I’ve helped customers develop motor shafts with eccentric diameters for better magnetic balance. These couldn’t be done with normal CNC lathes. We had to use 4-axis turning with live tooling.

So when someone says “I need a shaft,” I always ask, “What kind of shaft? What’s it used for?” Because machining a car axle and a stepper motor shaft is totally different.

What material is used for shafts?

Material choice is the first step. Pick the wrong one, and you waste time and money.

Most shafts are made from carbon steel, alloy steel, stainless steel, and sometimes aluminum or brass depending on strength and corrosion needs.

Here’s a simple chart of materials and where they’re used:

| Material | Key Property | Common Use Case |

|---|---|---|

| Carbon Steel (e.g. C45) | Strong and low cost | Standard transmission shafts |

| Alloy Steel (e.g. 42CrMo) | High strength | Heavy-duty shafts |

| Stainless Steel (e.g. 304/316) | Corrosion-resistant | Medical and marine shafts |

| Aluminum (e.g. 6061) | Lightweight | Drone or robotic shafts |

| Brass | Machinable and corrosion-resistant | Electronics connectors |

For long fasteners, I often recommend 12L14 or 1215 for easy machining, but only if strength isn't the main goal. If the shaft needs to be hardened, I go with 4140 or 40Cr. And when a German client asked for stainless motor shafts with a polished finish for marine equipment, we used 316L and centerless ground them to a mirror-like finish.

Remember, material also affects the machining method. Some steels need slower speed, others allow fast turning. And don’t forget—if the supplier doesn't ask you what the part is used for, be careful. They might just choose the cheapest steel.

Why are shafts made circular?

It seems obvious, but there's a reason shafts are round. It's not just tradition.

Shafts are made circular because round shapes distribute stress evenly during rotation and fit perfectly with bearings, which are also round.

A circular cross-section makes it easier to rotate without wobble. That's why all rotating parts, from simple bolts to high-speed spindles, are round. Round shafts reduce friction, wear less, and work well with ball bearings or bushings. Square or hex shapes would create vibration and uneven load.

There’s also a machining reason. Round shafts are easy to turn and grind. If you want a shaft with 0.01mm tolerance, you need a round blank and round cutting tools. Even threads, keyways, and knurls start from a round base.

One time, a customer insisted on a shaft with an elliptical cross-section. We tried, but the result was unstable. We ended up redesigning it to a round base with an offset feature. That’s another reminder: round works, not just for physics, but for machining.

Conclusion

To make long shaft-type non-standard fasteners well, you need the right machining setup, a deep understanding of materials, and close control of vibration and tolerance.