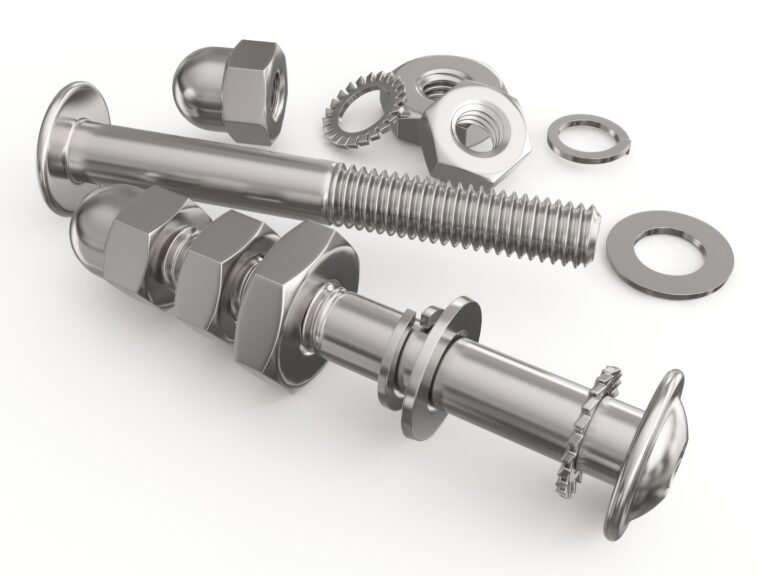

Non-standard nuts might look simple—but behind each custom design lies a chain of precision, materials, and inspection that can’t afford to go wrong.

To manufacture non-standard nuts correctly, focus on material selection, forming process, thread precision, and tight quality control across every production stage.

I've helped clients source custom nuts for everything from automotive to aerospace. These aren’t off-the-shelf items. Each one has special shapes, coatings, or mechanical demands. Getting them wrong means client rejections, machine failures, or loss of business. That’s why I always start with a detailed technical breakdown before even quoting. Here's what I look for at each stage of production.

How are nuts made step by step?

Understanding how nuts are made helps you see where quality issues can start and how to prevent them early.

Nuts are made by cold or hot forming, followed by tapping (thread cutting or rolling), heat treatment if required, and surface finishing for protection.

The first time I walked through a nut manufacturing line, I was amazed at how much engineering went into something so small. Each step is critical. When sourcing non-standard nuts, I always confirm that the factory can perform each step in-house or has certified partners.

Standard Nut Manufacturing Steps

| Step | What Happens | Key Checkpoints |

|---|---|---|

| Material Cutting | Wire or rod cut to length | Diameter and length tolerance |

| Forming | Shape is forged (cold or hot) | Shape integrity, crack-free corners |

| Trimming | Excess material is removed | Flatness and size uniformity |

| Threading | Threads are cut or rolled | Fit with mating bolt, pitch accuracy |

| Heat Treatment | Increases hardness or strength | Hardness range within spec |

| Surface Finishing | Zinc plating, black oxide, etc. | Corrosion resistance, appearance |

| Final Inspection | Measured and tested | 100% thread gauge pass, visual check |

For non-standard nuts, we might also add secondary machining like milling slots or cross holes. This adds time and cost, but it’s often required in high-precision applications.

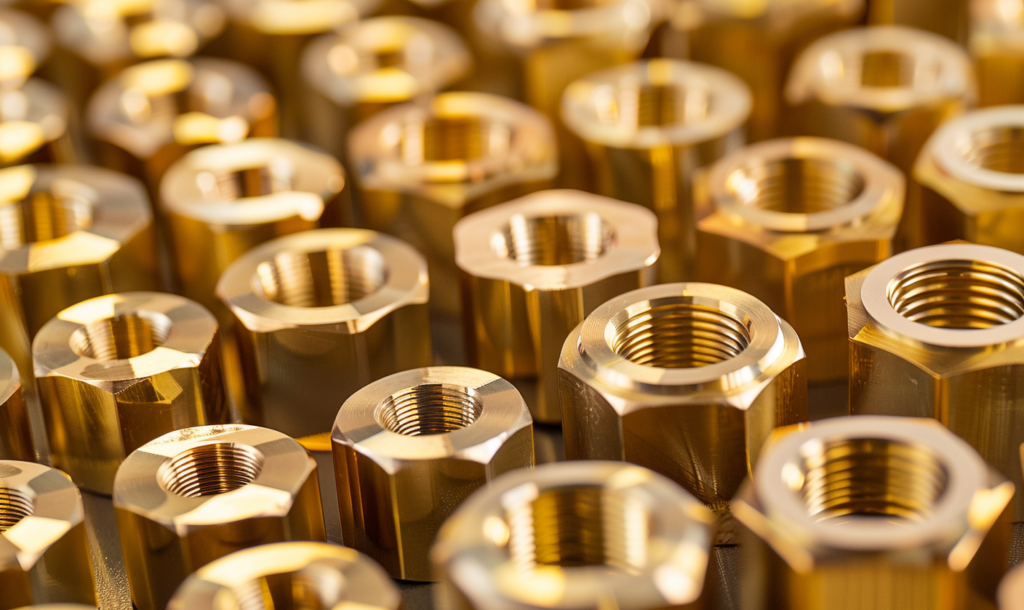

What is the raw material for nut bolt manufacturing?

Without the right material, even the best design fails in real-world use. The material must match the mechanical and environmental demands.

Common raw materials for nuts include carbon steel, stainless steel, brass, and alloy steel, depending on strength, corrosion resistance, and cost needs.

For my European clients, raw material traceability is non-negotiable. I always request mill certificates. For automotive nuts, we mostly use medium carbon steel like 1045 or 10B21. For marine or food-grade parts, it’s 304 or 316 stainless. Here's how I match material to the job.

Material Selection for Custom Nuts

| Material Type | Properties | Common Use Cases |

|---|---|---|

| Carbon Steel | Strong, low cost, needs plating | General mechanical applications |

| Stainless Steel | Corrosion-resistant, non-magnetic | Food, medical, outdoor machinery |

| Brass | Corrosion-resistant, good for conductors | Electronics, plumbing |

| Alloy Steel | High strength, heat treatable | Automotive, aerospace |

Some clients want light-weight parts. For those, I explore aluminum or even titanium nuts, although both require special machining due to their softness or cost. We also ask about any required standards—DIN, ISO, ASTM—to match regional expectations.

How many types of nuts are there in mechanical?

Nuts are more diverse than most people think. Each type serves a different mechanical or assembly need.

There are over 20 types of mechanical nuts, including hex nuts, lock nuts, flange nuts, wing nuts, and cap nuts, each designed for a specific purpose.

When a client asks for “just a nut,” I always ask more questions. Do you need a locking feature? Will it face vibration? Will it be hand-tightened or torqued by machine? The answers determine the nut type we recommend.

Common Types of Mechanical Nuts

| Nut Type | Key Feature | Typical Use |

|---|---|---|

| Hex Nut | Standard six-sided nut | General purpose |

| Lock Nut | Resists loosening due to vibration | Machinery, automotive |

| Flange Nut | Built-in washer surface | Distributes load without washer |

| Cap Nut | Closed-end to protect threads | Aesthetics, safety |

| Wing Nut | Tool-free hand tightening | Temporary assemblies |

| T-Slot Nut | Fits into machine slots | CNC, fixture setups |

For custom applications, I often work with engineers to modify a standard type. For example, we’ve added nylon inserts to custom lock nuts or extended the height of flange nuts for torque control. These details make the difference between a working part and a failed assembly.

How to measure nut size?

Correct nut measurement is essential for proper fit, torque control, and assembly performance.

Nut size is measured by thread diameter (nominal size), thread pitch, and across-flats (AF) dimensions using calipers and thread gauges.

In the early days, I once shipped M10 nuts that turned out to be coarse thread, while the client needed fine thread. That small mistake led to hundreds of rejected parts. Now, I always double-check three points: outer diameter, pitch, and height.

How to Measure a Nut

| Dimension | Tool Needed | What It Tells You |

|---|---|---|

| Thread Diameter | Vernier caliper | Nominal thread size (e.g. M8, M10) |

| Thread Pitch | Thread pitch gauge | Coarse or fine thread (e.g. 1.5mm) |

| Across Flats (AF) | Caliper or wrench | Spanner size compatibility |

| Overall Height | Caliper | Important for thread engagement depth |

I also ask clients to specify thread tolerance class (like 6H or 6G) if it matters for their assembly. Without it, the thread fit could feel too tight or too loose. And for special coatings, I allow for slight increases in size due to plating thickness.

Conclusion

Custom non-standard nuts demand precision at every step—from material to final measurement. Success means understanding the application, matching specs, and checking every detail.