I remember quoting both aluminum and steel for the same part—and the customer asked, "Which one should I choose?" That moment made me realize the value of clear guidance.

Aluminum is lighter and easier to machine. Steel is stronger and more wear-resistant. The right choice depends on strength, weight, cost, and performance needs.

Let’s look at how to decide between them in real sourcing scenarios.

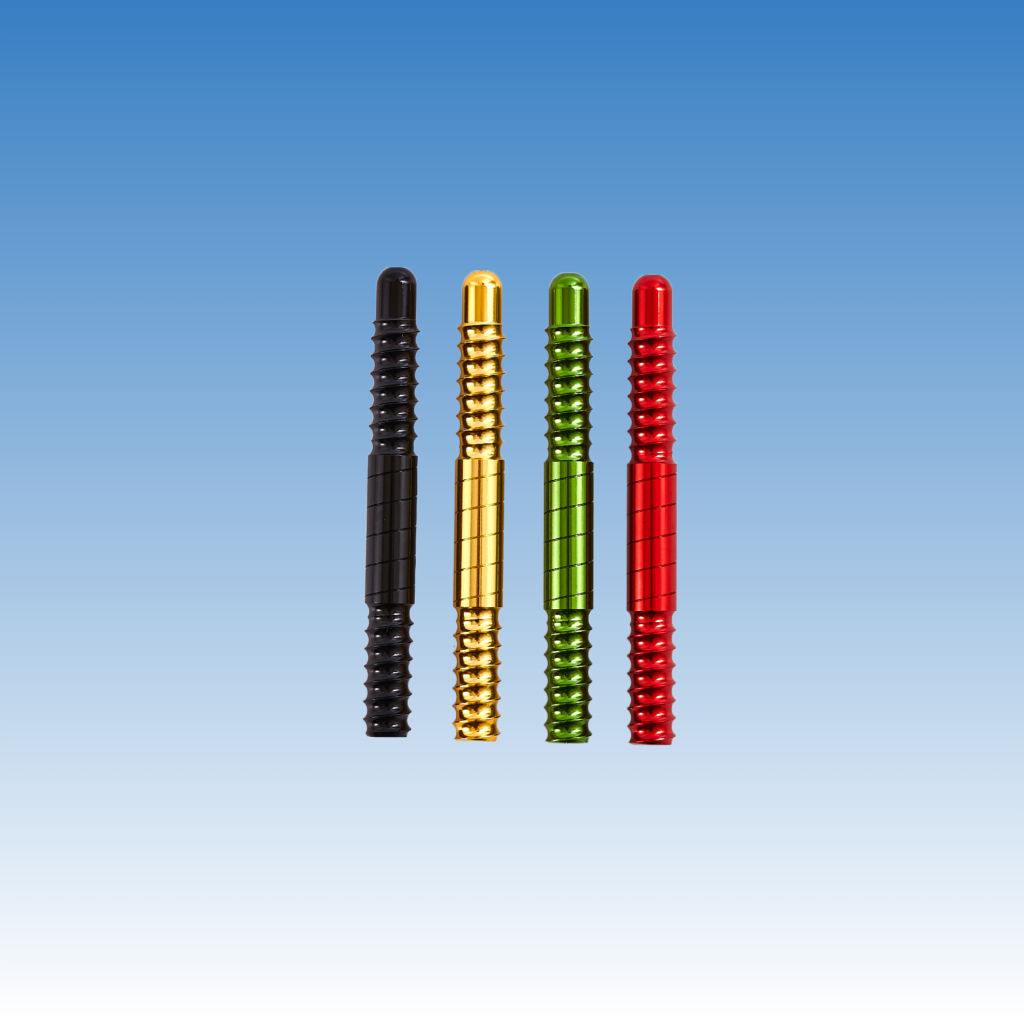

When should I choose aluminum vs steel?

Sometimes buyers just want the cheapest option—but that can cost more later if the material isn't right.

Choose aluminum for lightweight, corrosion-resistant parts. Choose steel when strength, hardness, or wear resistance is critical.

Let’s break it down by application:

| Use Case | Best Metal | Why |

|---|---|---|

| Aerospace parts | Alu | Lightweight, reduces fuel use |

| Machine frames | Steel | Rigid and durable |

| Automotive brackets | Steel or Alu | Depends on weight vs strength |

| Electronics housings | Alu | Cool-running and non-magnetic |

| Fasteners | Steel | High strength and hardness |

When I help clients like Oliver decide, I always ask: “Where is this part used?” That gives the best clue on what matters more—weight or strength.

Does aluminium have good machinability?

One client was shocked when his aluminum parts finished quicker—and cheaper—than expected.

Yes, aluminum has excellent machinability, especially in soft alloys like 6061 and 7075. It cuts cleanly, wears tools less, and allows faster production.

Aluminum is ideal for high-speed milling or turning. Here's how it compares:

| Material | Machinability Rating (100 max) | Notes |

|---|---|---|

| Aluminum 6061 | 90 | Very clean cutting |

| Steel 1018 | 65 | Requires more torque |

| Stainless 304 | 45 | Tends to gum up or harden |

| Brass | 85 | Smooth but more costly |

Aluminum’s low melting point also helps avoid tool overheating. That means longer tool life and better surface finishes.

So for high-volume parts where machining time matters, I often push aluminum first—unless the customer really needs the extra strength of steel.

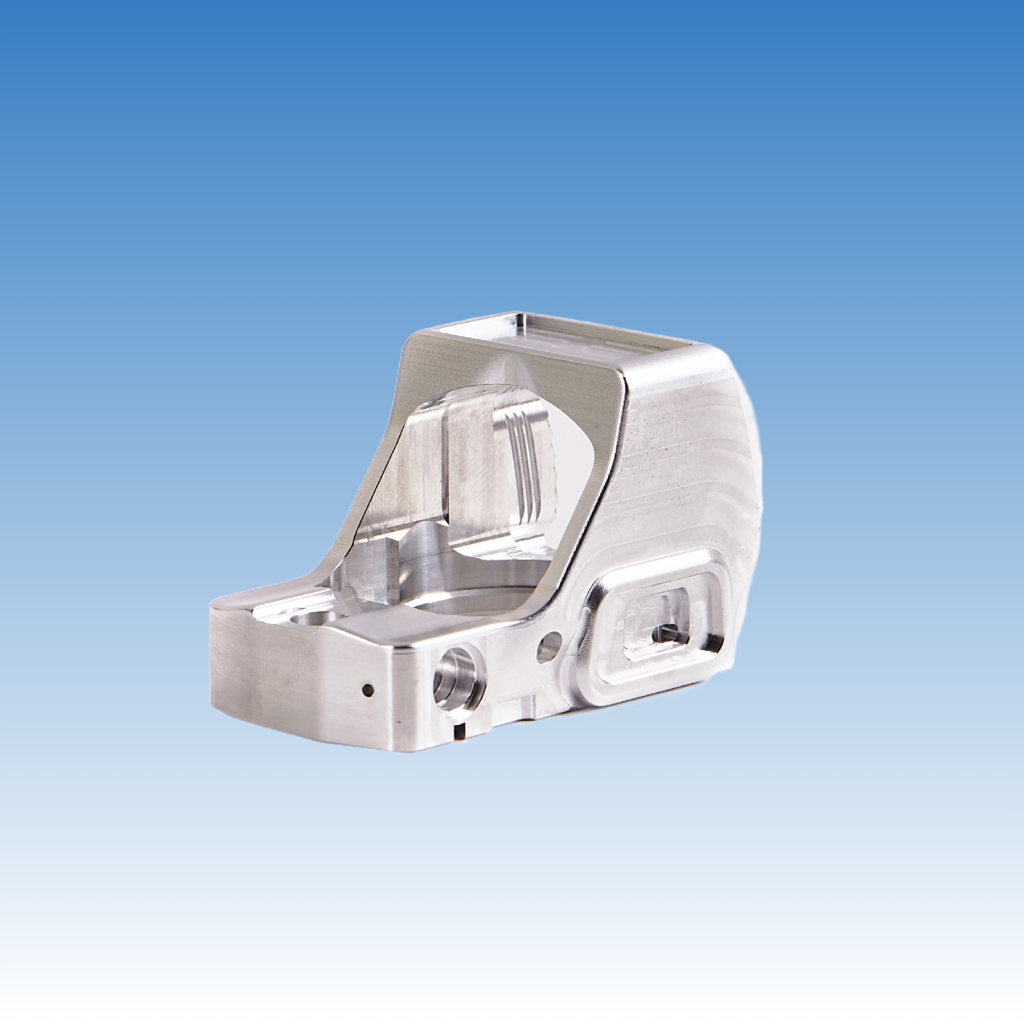

Why is aluminium preferred over steel?

One European distributor told me, “We prefer aluminum—it helps our designs look high-end and light.”

Aluminum is preferred because it's lightweight, corrosion-resistant, and easier to machine—saving time and reducing cost in many applications.

Let’s list what makes aluminum attractive:

- Weight: One-third the weight of steel

- Corrosion resistance: Forms a natural oxide layer

- Aesthetics: Easy to anodize for finish

- Machinability: Less wear on tools, faster speeds

- Thermal conductivity: Excellent for heat dissipation

Of course, steel wins in:

- Tensile strength

- Wear resistance

- Cost (in some grades)

But in industries like aerospace, electronics, and medical, aluminum is the first choice—due to performance-to-weight ratio.

I advise my customers: If your part doesn't face heavy stress and needs fast, clean production, go aluminum.

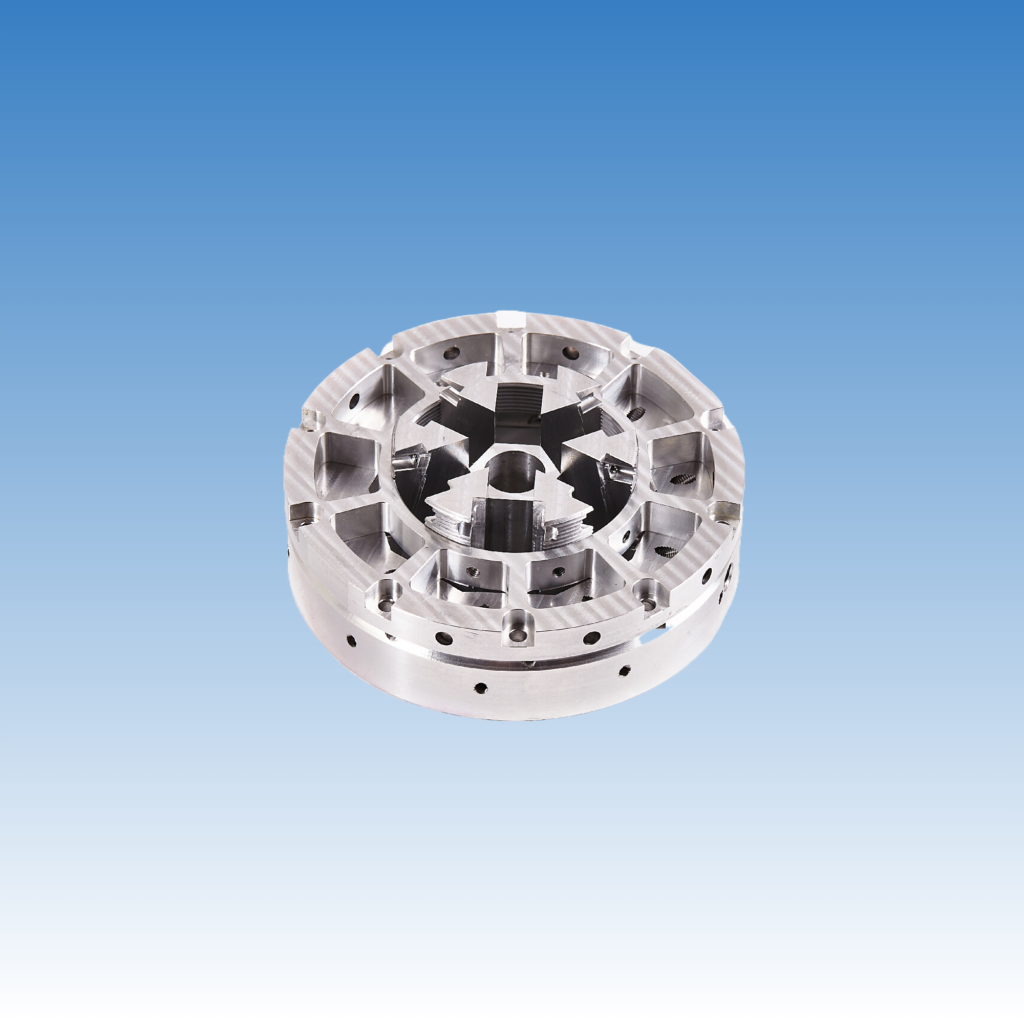

Which aluminum is best for machining?

I once used a cheap aluminum grade for precision bushings—it gummed up the tools and gave a bad finish. Wrong choice.

The best aluminum grades for machining are 6061-T6 for general use, and 7075-T6 when high strength is also needed.

Here’s a quick comparison:

| Grade | Machinability | Strength | Corrosion Resistance | Notes |

|---|---|---|---|---|

| 6061-T6 | Excellent | Medium | Very Good | Ideal for most CNC applications |

| 7075-T6 | Good | Very High | Moderate | Used in aerospace & auto |

| 2024 | Fair | High | Poor | Better for fatigue resistance |

| 5083 | Poor | Medium | Excellent | Good for marine use |

I always match the grade to the job:

- 6061: Best for brackets, housings, fixtures.

- 7075: Best for load-bearing arms, precision gears.

- 2024: Best for parts needing repeated stress.

- 5083: Best for marine equipment or salty environments.

I also recommend confirming tempers (like T6) with suppliers. These heat treatments affect strength and machinability.

Conclusion

Aluminum works better when you want speed, low weight, and corrosion resistance. Steel wins when strength or durability matters. Always match the material to the job—not just the cost.