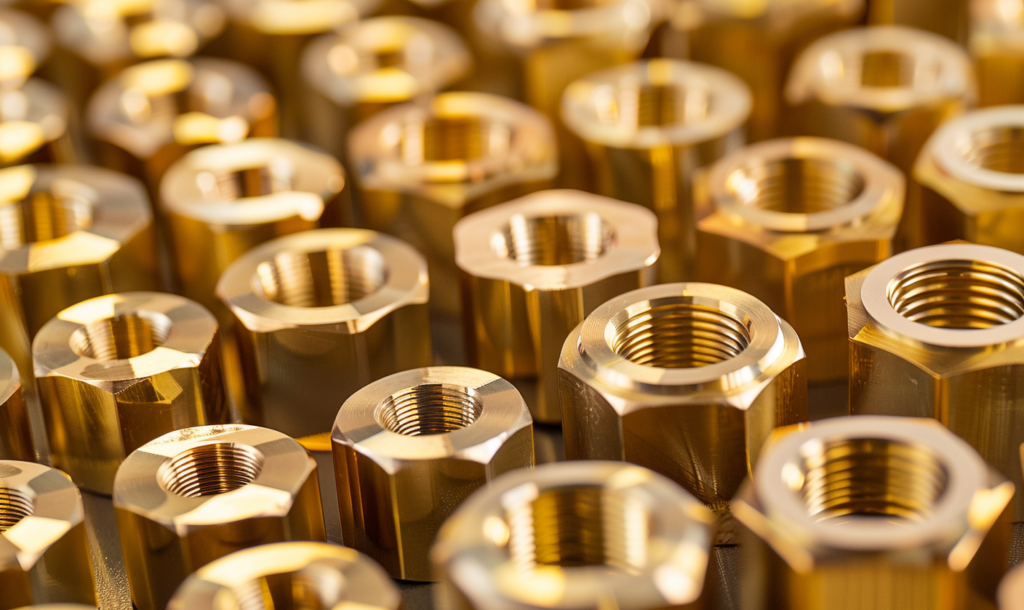

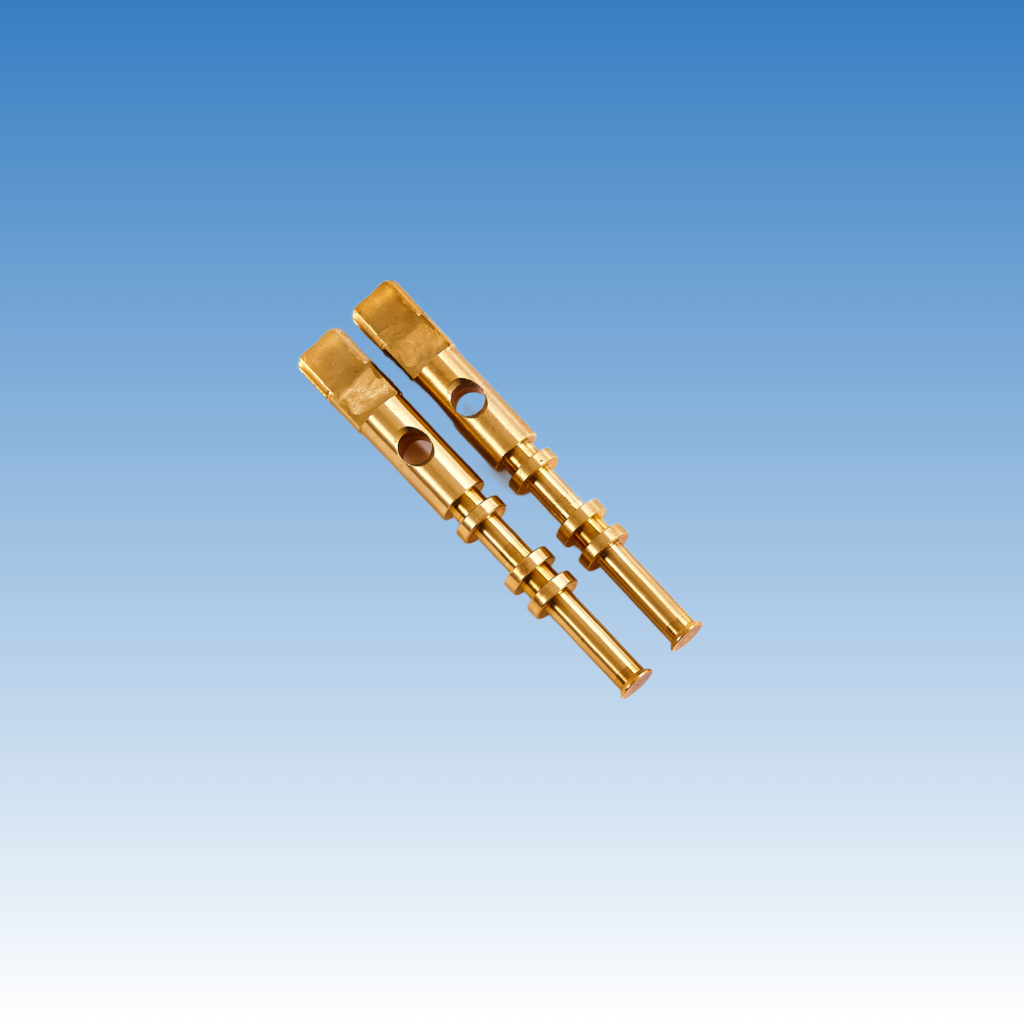

Many precision fasteners fail early because of poor surface protection. This causes costly replacements and safety risks in demanding industries.

ISO 1456 is applied to precision fasteners by defining electroplated coating requirements, corrosion resistance levels, thickness standards, and testing methods to ensure durable and reliable performance.

)

)

When I first learned about ISO 1456, I realized that many buyers were not only paying for parts but also for peace of mind. Precision fasteners hold machines together, and if a coating fails, the damage spreads beyond the part itself. That is why this standard matters to both suppliers and buyers.

What Are the Key Requirements of ISO 1456 in Fastener Plating?

Many fastener buyers worry about poor plating consistency. A coating that looks good at first may not meet industrial standards.

The key requirements of ISO 1456 in fastener plating include minimum coating thickness, uniform adhesion, corrosion resistance classes, and appearance standards for different plating types.

)

)

ISO 1456 sets rules for thickness, adhesion, corrosion resistance, and surface finish. It applies to fasteners plated with metals like nickel, chromium, or copper. Each requirement ensures fasteners meet functional needs in industries such as automotive or aerospace. For example, plating thickness depends on the exposure environment. In harsh conditions, thicker coatings are required. Adhesion tests prevent peeling during assembly. Appearance standards reduce surface variation, which affects not only looks but also mechanical fit. Below is a simple table that shows how ISO 1456 requirements link with fastener performance:

| Requirement | Purpose | Example in Fasteners |

|---|---|---|

| Coating thickness | Defines durability and resistance | Thicker nickel in marine fasteners |

| Adhesion tests | Prevents peeling under stress | Ensures stable torque in bolted assemblies |

| Corrosion resistance | Ensures service life | Zinc-nickel coating in automotive fasteners |

| Appearance standards | Improves consistency | Smooth finish in aerospace fasteners |

By meeting these requirements, precision fasteners stay reliable even in demanding fields.

How Does ISO 1456 Improve Corrosion Resistance in Precision Fasteners?

Rust and corrosion are the biggest threats to fastener life. Many buyers face hidden costs when parts fail too soon.

ISO 1456 improves corrosion resistance in precision fasteners by defining coating classes, specifying protective metal layers, and ensuring durability through accelerated corrosion tests.

)

)

The standard gives a clear framework for plating metals like nickel, copper, or chromium to fight corrosion. Each metal brings different benefits. Nickel provides strong base resistance, while chromium offers an extra barrier and better appearance. Copper can be used as an undercoat to improve adhesion. ISO 1456 also groups fasteners into corrosion resistance classes. These classes define how long a fastener should last in conditions like humidity or salt spray. For example, automotive bolts need higher protection than indoor machine screws. Accelerated tests, such as salt spray exposure, prove the coating’s performance. This prevents guesswork for buyers who need guarantees. Below is a table showing how coatings affect corrosion resistance:

| Coating Type | Corrosion Resistance Benefit | Application Example |

|---|---|---|

| Nickel plating | Strong base protection | Medical device fasteners |

| Chromium plating | Enhanced barrier, decorative finish | Aerospace visible fasteners |

| Copper undercoat | Improves adhesion, slows base corrosion | Automotive bolts before nickel |

| Zinc-nickel alloy | Superior resistance in salt environments | Marine equipment fasteners |

With these layers defined by ISO 1456, fasteners can resist corrosion much longer.

What Testing Methods Does ISO 1456 Require for Electroplated Layers?

Many suppliers promise quality plating but skip proper testing. This leads to fasteners that fail during use.

ISO 1456 requires testing methods such as coating thickness measurement, adhesion evaluation, corrosion resistance tests, and porosity checks for electroplated layers.

)

)

The standard lists specific testing methods to prove fastener reliability. Coating thickness can be measured using microscopic cross-sections or non-destructive instruments like X-ray fluorescence. Adhesion is tested by bending, heating, or taping the plated surface. Corrosion resistance is checked with salt spray tests, which simulate long-term exposure to harsh environments. Porosity tests are also required, since small holes in plating can speed up corrosion. These tests prevent weak fasteners from reaching the customer. I often remind clients that testing is not just paperwork; it saves them from warranty claims and damaged reputation. Here is a breakdown of ISO 1456 testing:

| Test Method | Purpose | Example in Use |

|---|---|---|

| Thickness measurement | Confirms plating meets standard | XRF test for nickel thickness |

| Adhesion test | Ensures coating does not peel | Bend test on small bolts |

| Corrosion resistance | Simulates harsh environment durability | 96-hour salt spray for automotive fasteners |

| Porosity test | Detects flaws in protective layer | Ferroxy indicator for chromium coatings |

These tests build trust between suppliers and buyers by showing real performance data.

How Can ISO 1456 Reduce Surface Defects in Precision Fasteners?

Surface defects cause assembly problems and shorten fastener life. Many buyers reject entire batches when plating shows poor finish.

ISO 1456 reduces surface defects in precision fasteners by setting appearance standards, controlling plating processes, and requiring inspections to eliminate cracks, pits, or uneven coatings.

)

)

The standard requires that coatings have uniform thickness and smooth finish. It limits defects like pits, cracks, and blistering, which often appear when plating is not controlled well. ISO 1456 also demands inspections during and after plating. This includes visual checks, microscopic analysis, and measurement of surface smoothness. These rules reduce batch rejections and improve production stability. For industries like aerospace, where even tiny defects can cause failure, these inspections are critical. I have seen buyers from Europe reject shipments for small surface flaws because they could not risk system failure. The table below explains how ISO 1456 reduces common defects:

| Defect Type | ISO 1456 Control Method | Benefit for Buyers |

|---|---|---|

| Pits or porosity | Process control + porosity test | Prevents hidden corrosion paths |

| Cracks or peeling | Adhesion testing + inspections | Ensures stable performance in assembly |

| Uneven coatings | Thickness measurement + standards | Maintains reliable torque in fasteners |

| Blistering | Surface cleaning + plating rules | Improves long-term reliability |

By applying these rules, suppliers can deliver fasteners that meet both technical and cosmetic requirements.

Conclusion

ISO 1456 helps precision fasteners last longer, look better, and perform safely by setting clear plating rules, corrosion resistance classes, testing methods, and surface finish standards.