Casting is one of the oldest yet most essential manufacturing processes in the metalworking industry. In modern applications across automotive, aerospace, machinery, energy, and transportation sectors, metal casting continues to play a vital role—especially when it comes to producing complex, large-volume parts with balanced cost and performance.

This article provides a complete overview of the casting process in precision manufacturing, outlining its benefits, limitations, and key technologies. It also compares different casting methods to help engineers, designers, and procurement professionals make informed decisions.

What is the Casting Process?

Casting is a manufacturing method in which molten metal is poured into a pre-designed mold cavity, cooled, and solidified to form a desired shape. After removing the mold, further finishing steps like cleaning, machining, and surface treatment may follow.

The casting process flow typically includes:

- Mold preparation (sand mold, metal mold, ceramic shell, etc.)

- Melting and pouring

- Cooling and solidification

- Shakeout and surface cleaning

- Post-processing (heat treatment, machining)

Casting is divided into several categories based on precision, mold material, and pouring method, including:

- Sand Casting

- Investment Casting (Precision Casting / Lost Wax Casting)

- Die Casting

- Shell Mold Casting

- Permanent Mold Casting

- Centrifugal Casting

Each method has specific strengths and is suited for different part geometries, materials, and production volumes.

Ⅰ. Advantages of the Casting Process in Precision Manufacturing

Casting offers a range of benefits in high-efficiency precision manufacturing, making it an ideal solution for complex and large parts.

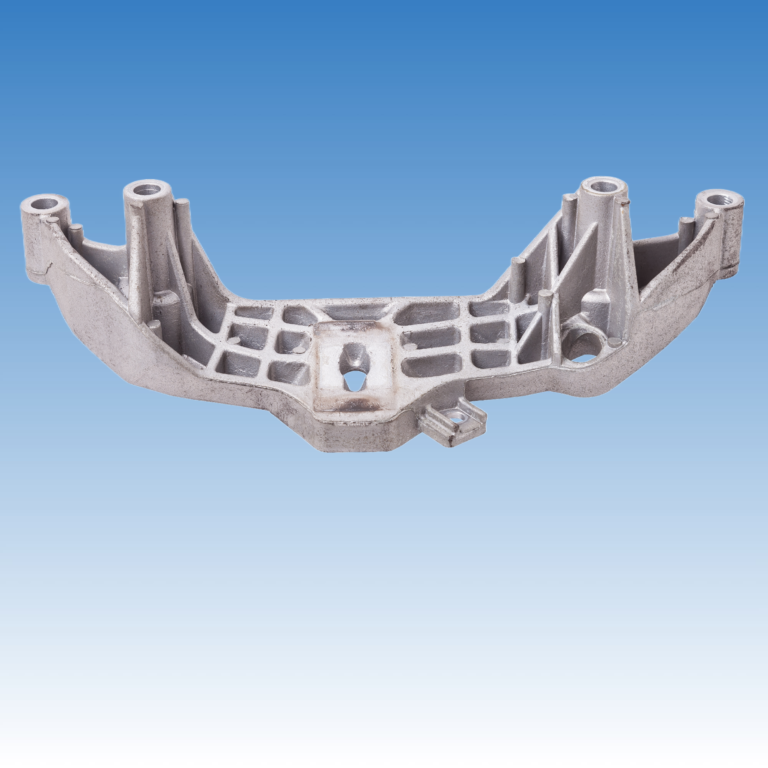

- Ideal for Complex Geometries

Casting allows the creation of intricate internal structures, undercuts, and complex shapes in one process—without the need for welding or multiple machining steps. It is commonly used for pump housings, valve bodies, enclosures, and automotive engine parts.

- Suitable for a Wide Range of Metals

Almost all meltable metals—including cast iron, cast steel, stainless steel, aluminum alloys, and copper alloys—can be processed through casting.

- Cost-Effective for Mass Production

Once the mold is developed, the unit cost of each part drops significantly, making casting highly efficient for medium- to large-scale production.

- Wide Size Range

Casting supports a broad size spectrum, from a few grams to several tons—making it one of the most flexible manufacturing techniques.

- Near-Net Shape Manufacturing

With controlled process parameters, casting can produce parts that are close to final dimensions, reducing material waste and machining time.

Ⅱ. Disadvantages and Challenges of the Casting Process

Despite its many advantages, the casting process does have limitations—especially when high-precision or zero-defect requirements are involved.

- Limited Dimensional Accuracy and Surface Finish

Traditional casting methods like sand casting may not meet the precision required for tight tolerance parts. Secondary machining is often required.

- Common Casting Defects

Casting is prone to internal and external defects such as porosity, shrinkage cavities, inclusions, and hot cracks. Strict quality control (NDT, X-ray, ultrasonic testing) is necessary.

- Long Lead Time for Mold Fabrication

Mold making for precision casting is time-consuming and expensive, making the process less flexible compared to CNC or additive manufacturing.

- Deformation and Shrinkage Control

During cooling and solidification, uneven stress can lead to part deformation—especially in thin-walled or asymmetrical components.

- Inconsistent Material Structure

Castings may have non-uniform microstructures or coarse grains, affecting mechanical properties compared to forged or extruded parts.

Ⅲ. Comparison of Common Casting Methods

| Casting Method | Precision | Cost | Suitable Materials | Typical Applications |

| Sand Casting | Low–Medium | ★ | Iron, steel, aluminum | Large housings, pump bodies, engine blocks |

| Investment Casting | High | ★★☆ | Stainless steel, alloy steel | Turbine parts, precision mechanical parts |

| Die Casting | Very High | ★★★ | Aluminum, zinc | Automotive components, electronic housings |

| Permanent Mold | Medium | ★★ | Aluminum, copper | Pistons, impellers, structural parts |

| Centrifugal Casting | Medium–High | ★★ | Alloy steel, cast iron | Pipe fittings, ring-shaped components |

If you need cost-effective casting for large parts, sand casting is a good choice. For high-precision and high-performance parts, investment casting or die casting is preferred.

Ⅳ. Trends in Modern Casting Technology

As digital manufacturing and smart factories advance, casting is evolving through the integration of new technologies:

- 3D Printed Sand Molds – Accelerate prototyping and reduce mold development time

- CAE Simulation Tools – Predict and minimize casting defects through flow and solidification analysis

- Robotic Molding and Cleaning – Improve consistency and reduce labor dependency

- Digital Traceability Systems – Ensure quality control and part traceability across batches

These innovations are driving casting from a labor-intensive process toward data-driven, intelligent precision manufacturing.

Ⅴ. Summary: Balancing the Pros and Cons of Casting

In summary, the casting process offers unmatched advantages for producing complex, large-volume metal components across many industries. It supports near-net shaping, material versatility, and cost efficiency. However, it also faces challenges in terms of precision, defect control, and production flexibility.

To maximize benefits, manufacturers often combine casting with secondary machining, or leverage modern casting simulations and inspection tools to ensure quality.