The choice of materials is crucial in the production of precision fasteners. Aluminum alloys, known for their lightweight, high strength, and excellent machinability, are widely used in the manufacturing of precision fasteners for industries such as automotive, aerospace, and electronics. This article provides a detailed introduction to the common aluminum materials used for precision fasteners and their respective advantages and disadvantages, helping you better understand the application of aluminum materials in precision fastener manufacturing.

Ⅰ. Common Types of Aluminum Materials

In the production of precision fasteners, the commonly used aluminum alloys include the following types:

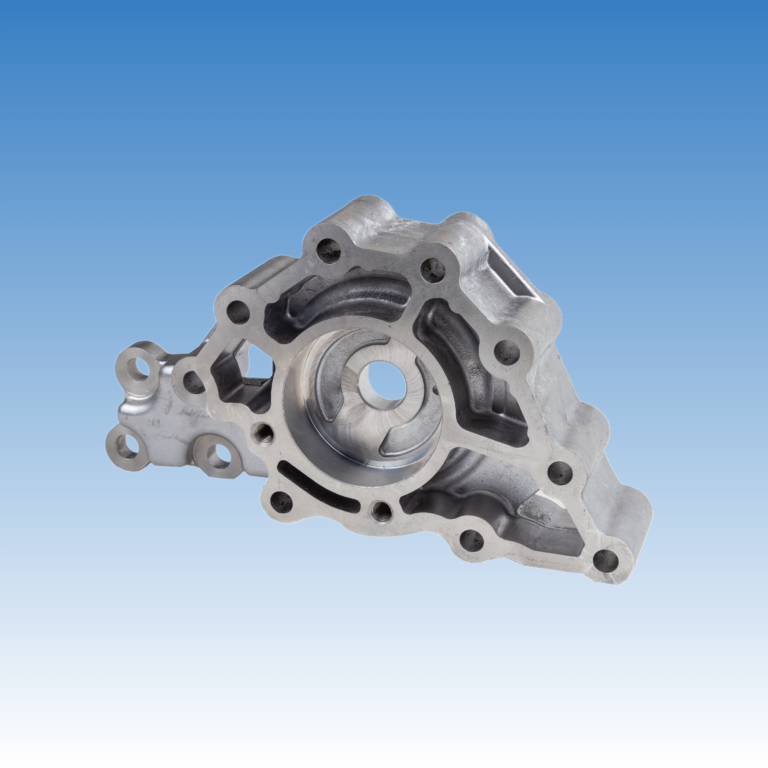

1. Aluminum Casting Alloys

Aluminum casting alloys are produced using casting processes, offering excellent fluidity and formability, making them ideal for manufacturing complex-shaped fasteners. Common aluminum casting alloys include A356 and ADC12, among others.

2. Aluminum Forging Alloys

Aluminum forging alloys are produced through forging processes, offering good mechanical properties and fatigue resistance. Common forging alloys include 2024, 7050, and 7075, widely used in aerospace and high-load environments for fasteners.

3. Aluminum Extrusion Alloys

Aluminum extrusion alloys are suitable for mass production, enabling the rapid and precise production of complex fastener shapes. Common extrusion alloys include 6061, 6063, and 6082, which are popular for their good mechanical properties and ease of processing.

4. Aluminum Alloy Plates

Aluminum alloy plates are typically used for manufacturing thin, precision fasteners, providing good flatness and surface smoothness. Common plate alloys include 5052 and 5083, among others.

Ⅱ. Advantages of Aluminum Materials in Precision Fasteners

1. Lightweight and High Strength

Aluminum alloys have a relatively low density, approximately one-third that of steel, making aluminum-based precision fasteners significantly lighter. In industries such as aerospace and automotive, reducing weight is key to improving efficiency and performance, making aluminum fasteners an ideal choice.

2. Excellent Corrosion Resistance

The surface of aluminum alloys naturally forms an oxide layer, providing strong corrosion resistance. In harsh environments such as humidity or salt spray, aluminum fasteners can maintain a longer service life. This property makes them widely used in outdoor and marine environments.

3. Good Machinability

Aluminum materials have excellent cutting properties, allowing for the cost-effective and precise manufacture of precision fasteners. Their excellent weldability and surface treatment capabilities enable aluminum alloys to meet design requirements more effectively.

4. Good Electrical and Thermal Conductivity

Aluminum alloys offer good electrical and thermal conductivity, making them ideal for fasteners used in heat dissipation applications. For example, aluminum fasteners in electronic devices can help the equipment dissipate heat more efficiently, improving performance and extending the service life of the device.

5. Recyclability

Aluminum is one of the most recyclable metals on Earth. Aluminum alloy fasteners can be reused through recycling, significantly reducing production costs and aligning with modern environmental concerns.

Ⅲ. Disadvantages of Aluminum Materials in Precision Fasteners

1. Relatively Low Strength

While aluminum alloys offer significant advantages in terms of weight and machinability, their relatively low strength remains a major drawback. Especially in high-load or high-stress environments, the strength and wear resistance of aluminum alloys are inferior to that of steel. Therefore, aluminum fasteners may not perform as well in these types of applications.

2. Insufficient Hardness

Aluminum alloys tend to have lower hardness, particularly under high temperatures, where aluminum fasteners may experience surface wear or deformation. To improve hardness, aluminum alloys often require heat treatment or surface hardening processes such as anodizing.

3. Sensitive to Temperature Changes

Aluminum alloys have a relatively high coefficient of thermal expansion, meaning they may expand or contract when exposed to significant temperature variations, affecting the fastening performance. In high or low-temperature environments, the mechanical properties of aluminum alloys may decrease, necessitating careful consideration in design.

4. Prone to Fatigue Fracture

Over prolonged use, aluminum alloys can experience fatigue fractures, especially when subjected to repetitive stresses. This could compromise the reliability and safety of precision fasteners that are used for extended periods. Therefore, material selection and processing need to be closely monitored in design and manufacturing.

5. Surface Treatment Challenges

Although aluminum alloys offer good surface treatment properties, their surfaces are prone to scratches, impacts, and other mechanical damage, which can reduce the surface quality. In precision fasteners, surface smoothness and wear resistance are crucial, so special attention must be given to surface treatment processes, such as anodizing or electroplating.

Ⅳ. Future Prospects of Aluminum Materials in Precision Fasteners

Despite some drawbacks, the future application of aluminum alloys in precision fasteners remains promising, thanks to ongoing developments in new aluminum alloy materials and advanced processing technologies. Aluminum alloys are increasingly used in industries such as aerospace, automotive lightweighting, electronics, and medical devices.

In recent years, high-strength aluminum alloys have been developed that maintain a good lightweight characteristic while improving strength. Additionally, surface treatment technologies for aluminum alloys continue to evolve, with new coating technologies enhancing hardness and corrosion resistance, thus broadening the scope of their application in precision fasteners.

Ⅴ. Conclusion

As a widely used material for precision fasteners, aluminum alloys offer numerous advantages, such as being lightweight, high-strength, corrosion-resistant, easy to process, and recyclable. These properties make them particularly suitable for applications that require low weight, excellent corrosion resistance, and good machinability. However, aluminum alloys also have their limitations, including lower strength, insufficient hardness, sensitivity to temperature changes, and susceptibility to fatigue fracture. Therefore, when selecting aluminum alloys for precision fasteners, it is essential to carefully consider the specific operating environment and performance requirements to ensure that the material’s capabilities are fully utilized.