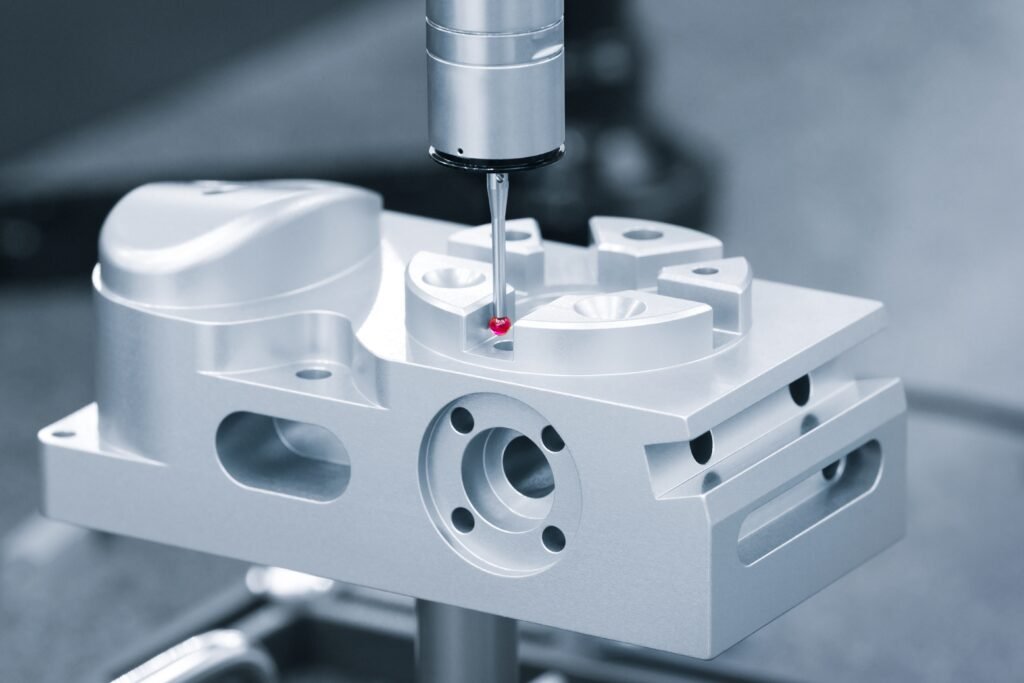

Machining fasteners looks simple, but once deformation shows up, even the best machines can’t guarantee good parts.

To prevent deformation during machining, control cutting force, temperature, and stress release through proper tooling, process planning, and material handling.

It’s a frustrating problem. I’ve had buyers reject large batches over small deviations in shape. They think we did something wrong. Sometimes, they’re right. But often, it's due to a mix of design, material, and processing choices. Let me break it down.

What is deformation in machining?

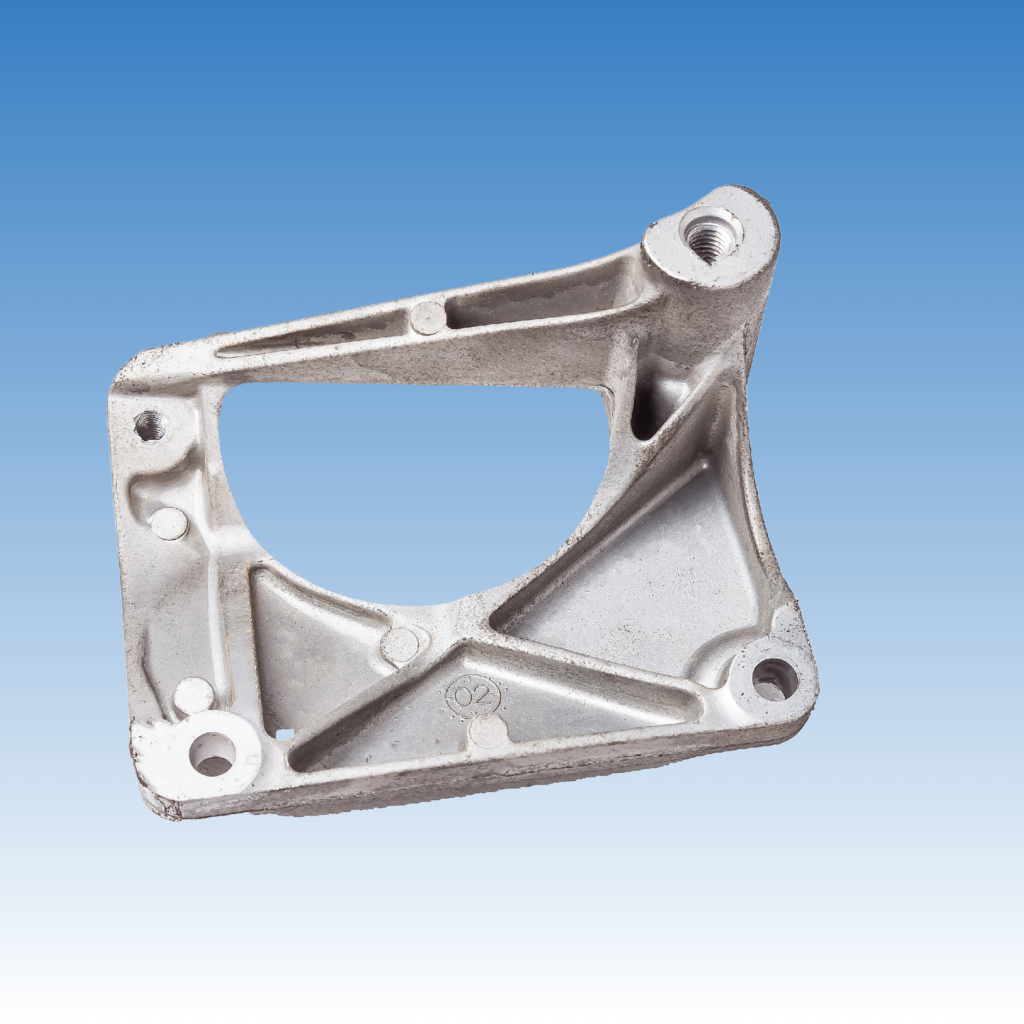

Even small forces can bend or twist your parts if not controlled properly.

Deformation in machining means unwanted changes in shape, usually caused by cutting forces, heat, or internal stress release during the process.

In machining, deformation usually means parts don’t meet dimensional tolerances anymore. It can happen in soft materials like aluminum, or even in hardened steels if we use improper cutting conditions. For fasteners, deformation often affects the threads, head, or shaft straightness. This causes trouble in assembly and leads to rejection. We need to manage the causes: cutting force, vibration, heat buildup, and internal stress.

Typical Causes of Deformation in Machining

| Cause | Description |

|---|---|

| Cutting Force | Excessive force bends or stretches the part during turning or milling |

| Residual Stress | Internal stress from previous processes gets released during machining |

| Heat Buildup | High temperatures cause thermal expansion or soften the material |

| Poor Fixturing | Weak clamping allows the part to move or vibrate |

| Tool Wear | Worn tools increase force and temperature during cutting |

What is warping in machining?

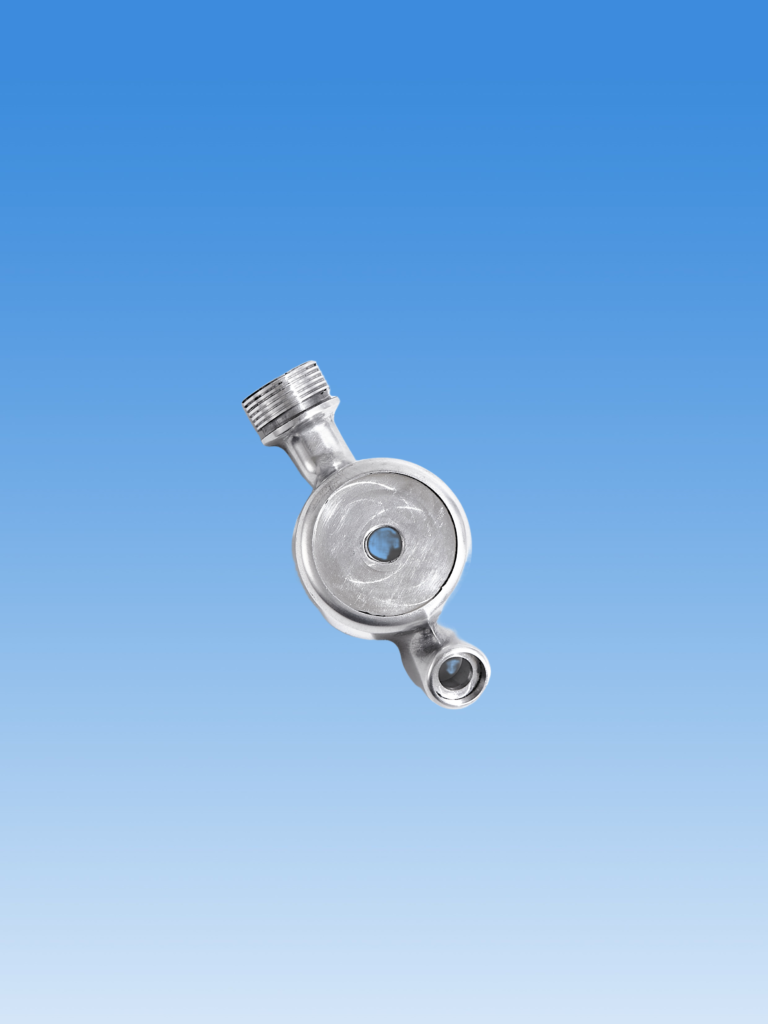

Thin or long parts can bend even after they leave the machine. This is warping.

Warping in machining refers to gradual bending or twisting of parts due to uneven stress relief or heat exposure after the cutting process.

Warping often shows up during or after the cooling stage. I’ve seen long bolts or shafts come out straight, but curve slightly a few hours later. It’s common in parts with thin cross-sections or uneven wall thickness. For fasteners, warping can ruin thread alignment or prevent proper fit. We fight warping by adjusting the roughing and finishing sequence, using stress relief heat treatment, and balancing material removal on both sides.

Techniques to Prevent Warping

| Method | How It Helps |

|---|---|

| Symmetrical Machining | Balances internal stress from both sides |

| Pre-Machining Stress Relief | Reduces hidden tension in raw material |

| Proper Coolant Use | Controls temperature and avoids thermal distortion |

| Finish Pass at Low Depth | Minimizes new stresses in the final stages |

| Material Selection | Some alloys are more stable under machining stress |

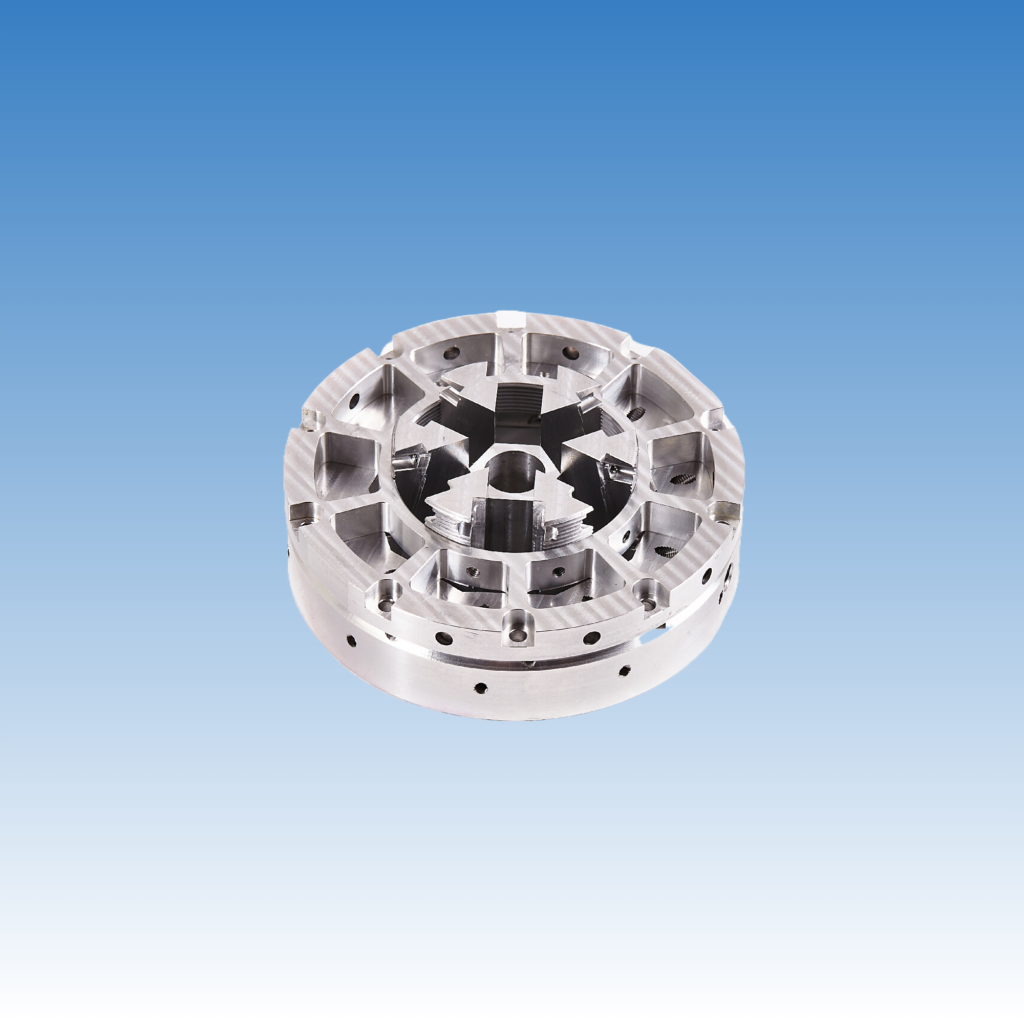

What is deformation in manufacturing process?

Not all deformation happens during machining. Some start earlier.

In manufacturing, deformation refers to any unintended shape change caused by force, heat, or stress from casting, forging, machining, or handling.

When I buy raw material from suppliers, I sometimes see mild bends or twists even before the first cut. It can come from hot rolling, cold forming, or poor storage. In machining, we inherit those problems and sometimes make them worse. For fasteners, if the raw blank is bent or stressed unevenly, it will likely deform more during cutting. We need to inspect the raw stock, and sometimes normalize or anneal it before use. That takes time, but it saves headache.

Common Deformation Sources in the Manufacturing Flow

| Stage | Deformation Risk |

|---|---|

| Casting | Uneven cooling causes internal stress |

| Forging | Non-uniform pressure bends the grain |

| Heat Treatment | Rapid quenching distorts geometry |

| Handling | Storage conditions cause bending |

| Machining | Final stress release leads to movement |

What is the difference between distortion and warping?

People use the words loosely, but in machining, they have different causes.

Distortion is any unplanned shape change, while warping specifically means slow bending or twisting due to uneven stress or temperature.

In my experience, distortion happens fast. For example, you mill one side of a flange, and the whole piece moves. That’s distortion from internal stress. Warping, on the other hand, may take hours. You machine a long part, it looks fine, and then it slowly curves as it sits on the shelf. That’s warping. Both are forms of deformation. Both need attention, especially for precision parts like fasteners. The fix is always in the process: balancing cuts, selecting the right sequence, and controlling heat.

Key Differences Between Distortion and Warping

| Feature | Distortion | Warping |

|---|---|---|

| Time | Happens quickly during or right after cut | Happens slowly, often after cooling |

| Cause | Sudden release of internal stress | Gradual release or uneven cooling |

| Shape | Irregular bending, twisting, or shifting | Smooth, continuous bending |

| Detection | Immediately visible | Often seen hours or days later |

| Prevention Method | Stress relief, balanced cuts | Thermal control, symmetrical machining |

Conclusion

To stop fastener deformation during machining, we need to control stress, temperature, and cutting forces from the raw material to the final cut.