When your anodized aluminum parts don't match, everything else falls apart—especially in industries where appearance is quality.

To get consistent anodized aluminum colors, control the alloy, surface finish, pretreatment, anodizing parameters, and dyeing steps. Good suppliers track these carefully and run samples before full production.

The color mismatch issue doesn’t just affect the look—it can affect your client’s confidence. Even one small part that looks different may raise concerns about your quality control. That’s why this topic matters to anyone sourcing or selling machined aluminum parts.

Why do anodized aluminum parts come out in different shades?

Color mismatches can look like poor quality—even if the part performs just fine.

The differences in aluminum alloy composition, surface roughness, and anodizing parameters are the most common reasons for color mismatches in anodized parts.

"Aluminum Alloy Color Variance")

"Aluminum Alloy Color Variance")

What affects the final color?

| Factor | Influence on Color |

|---|---|

| Aluminum Alloy Type | Different 6000, 7000 series absorb dye differently |

| Surface Finish | Polished vs. matte finishes reflect light differently |

| Pretreatment Chemicals | Change surface characteristics that hold dye |

| Anodizing Thickness | Thicker layers may absorb more or less dye |

| Dye Concentration & Time | Too much/little dye leads to weak or oversaturated color |

| Temperature & Agitation | Affects how dye interacts with oxide layer |

I’ve seen cases where two batches made from 6061 aluminum looked different—just because one had slightly more copper content. It’s almost impossible to match colors if the alloy isn’t controlled tightly. That’s why I always check material certs before approving mass production.

Can you control anodizing consistency across suppliers?

When one supplier gives you beautiful samples, but the mass batch looks off—it’s frustrating.

To maintain consistency across suppliers, you need to standardize all inputs: material source, surface treatment, bath composition, temperature, time, and rinse quality. Documentation and testing are essential.

What controls help?

| Control Point | What to Standardize |

|---|---|

| Incoming Material Cert | Use one supplier for base material |

| Pretreatment SOP | Use same chemicals and etch times |

| Anodizing Bath Monitoring | Regular pH, temp, voltage, and concentration checks |

| Dyeing Process Documentation | Exact dye mix ratio, temperature, duration |

| QA Sampling Plan | Inspect samples at every shift or 50 pcs |

When I worked with a new supplier in Ningbo, I sent over a very specific SOP document. It included everything—from exact part orientation during anodizing, to how long to rinse after dyeing. This helped me cut color deviation by 80% over the next two months.

What colors are hardest to match in anodizing?

Some colors are just harder than others to keep consistent.

Dark and vibrant colors like red, black, and blue are the hardest to match because small process changes cause big visual differences. Natural and light colors are easier.

"Anodized Aluminum Color Options")

"Anodized Aluminum Color Options")

Why are dark colors tough?

| Color | Matching Difficulty | Reason |

|---|---|---|

| Natural/Silver | Easy | No dye used |

| Gold | Moderate | Depends on alloy and light conditions |

| Red | Hard | Sensitive to temperature & time |

| Black | Very Hard | Shows even small inconsistencies |

| Blue | Hard | Dye penetration varies by batch |

I once had a batch of red parts rejected by a German buyer, even though all other specs passed. The color was just slightly off compared to the sample. Since then, I always ask my supplier to anodize one extra sample with each new batch, and I keep it as a reference.

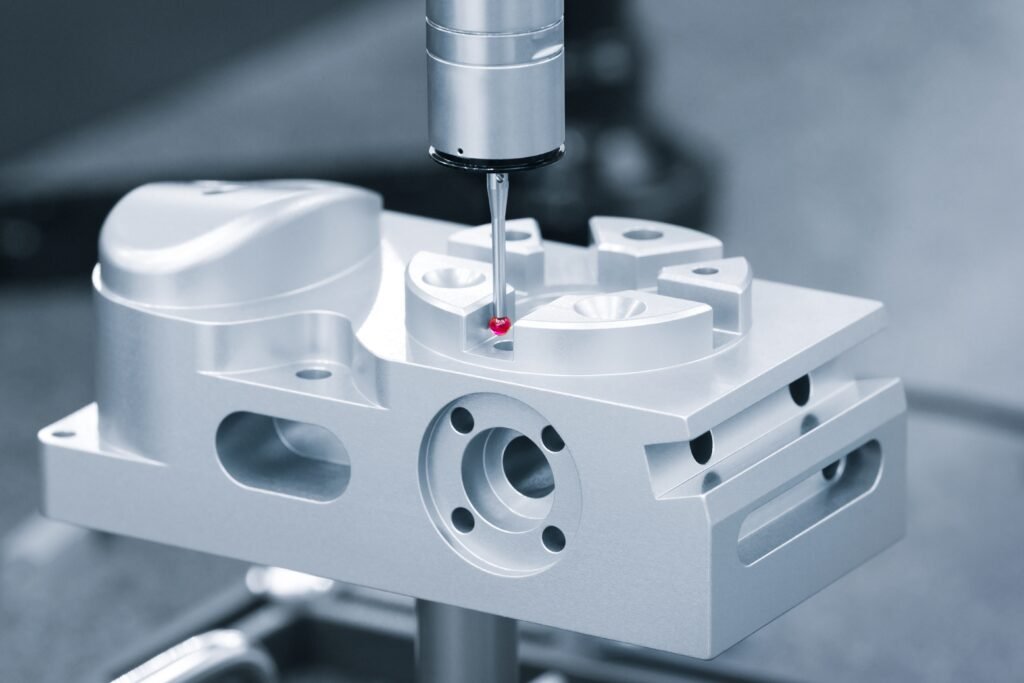

How do you test and control color accuracy in practice?

No one wants to argue about whether a part “looks right.”

Use visual color standards, spectrophotometers, and real-time feedback loops during production to control anodizing color results.

Best Practices for Quality Control

| Method | Description |

|---|---|

| Visual Standard Board | Keep approved samples under consistent lighting |

| Spectrophotometer Reading | Use Lab values to track deviations |

| Sample Approval Process | Approve first article before mass production |

| Lot Numbering | Track every batch to its raw material source |

| Retained Sample Archive | Keep samples for reference and dispute resolution |

Some of my most trusted suppliers send me both a digital spectrometer report and a physical sample with every shipment. This makes it easier to show clients that we care about color matching just as much as they do.

Conclusion

Matching anodized colors takes full control of every detail—from alloy to final inspection. It's not easy, but it's worth it.