Machining non-standard parts can feel like navigating a maze—tight tolerances, complex shapes, and varied materials mean one wrong decision leads to costly waste.

Non-standard parts machining demands tool materials that can handle complexity, irregular shapes, and a wide range of materials without compromising accuracy or tool life.

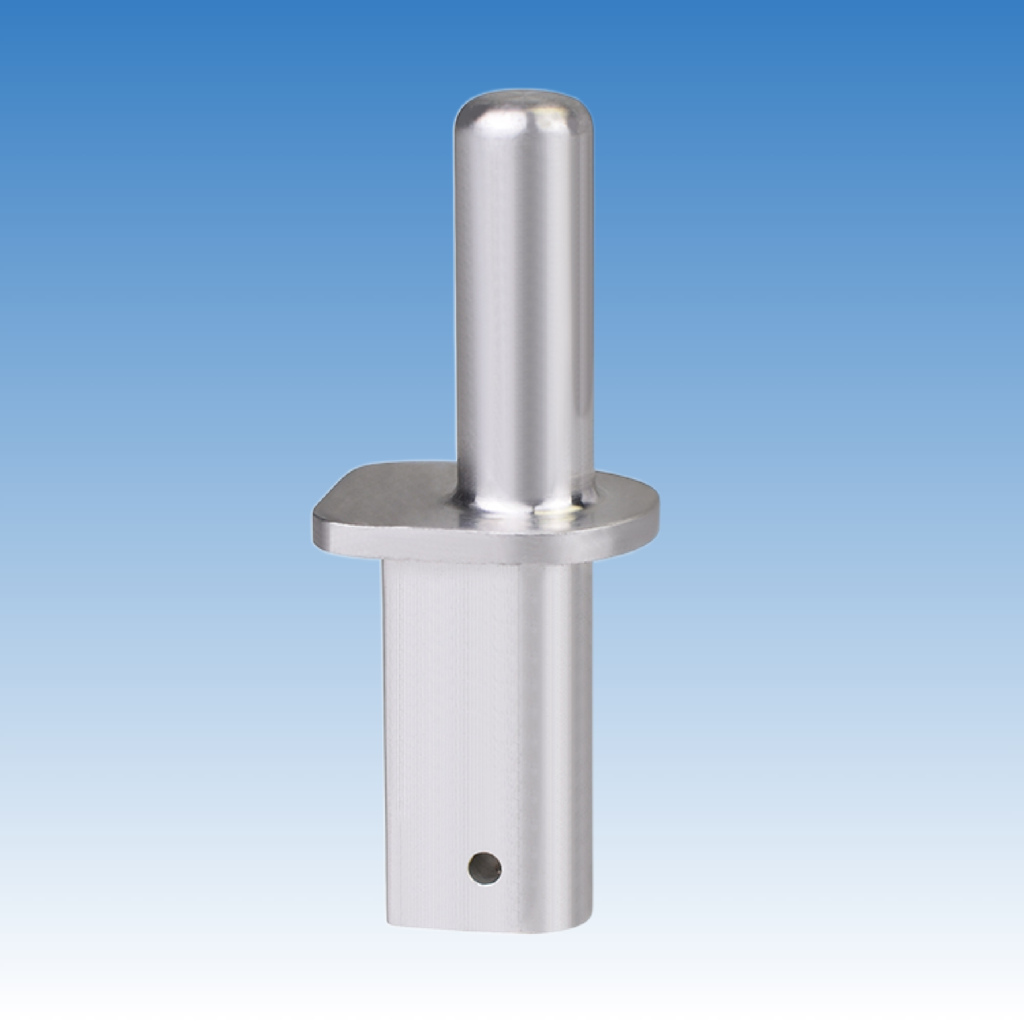

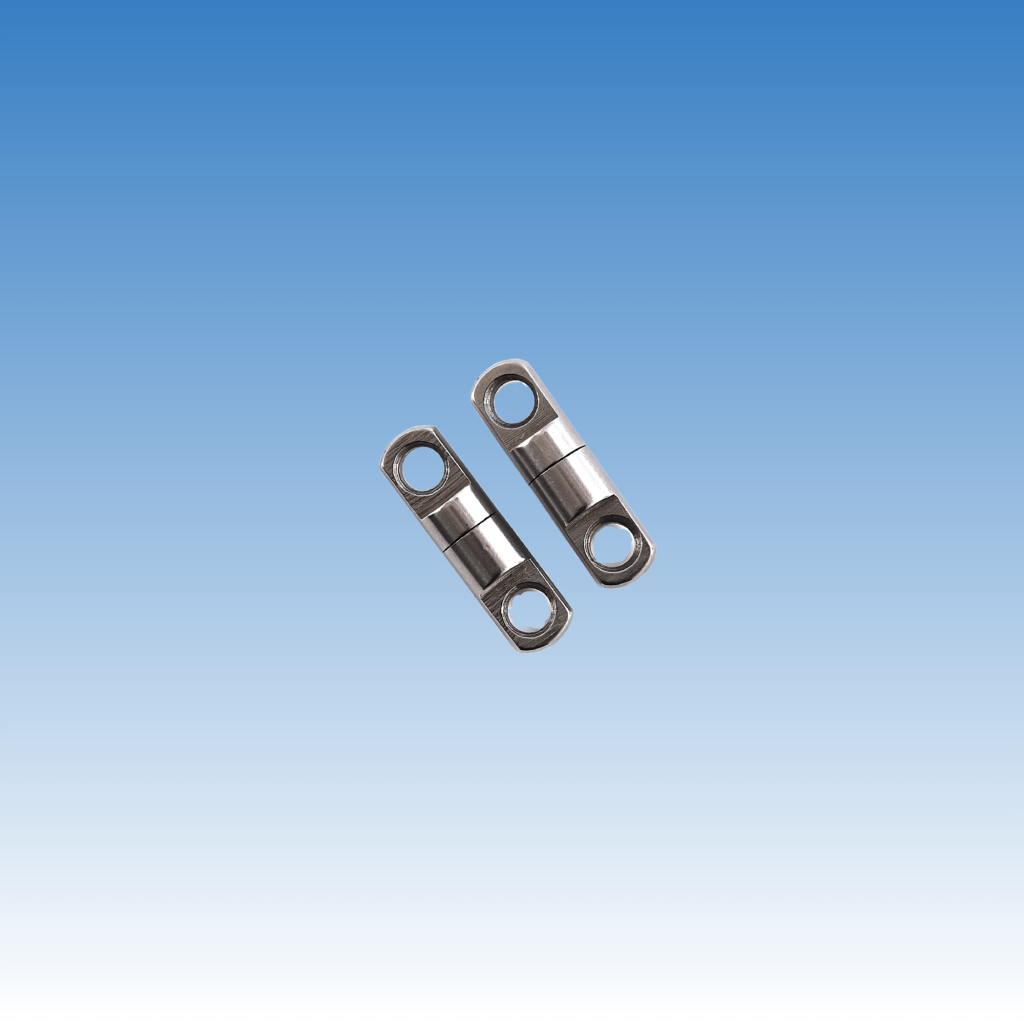

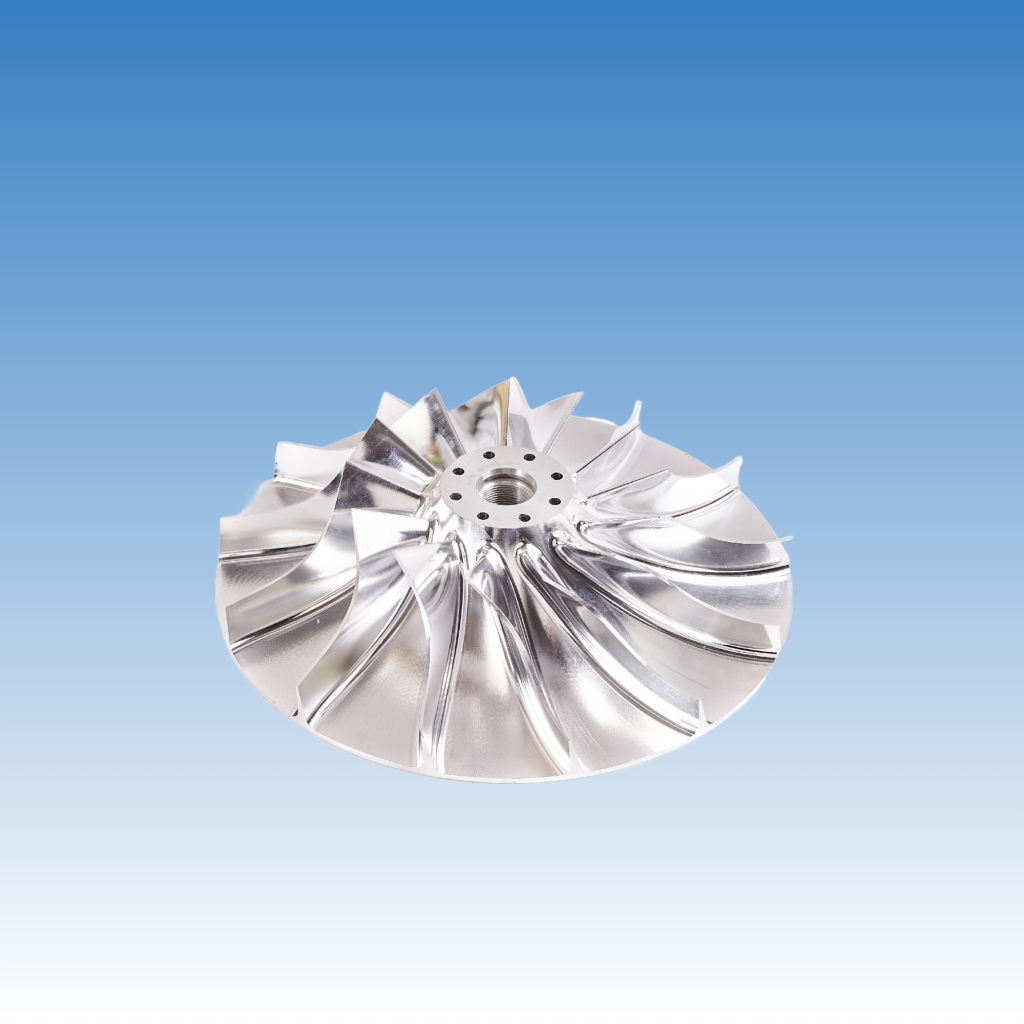

When I first started handling inquiries for custom parts, especially from industries like medical or aerospace, I realized that standard solutions didn’t apply. These parts had no universal blueprint. They often involved exotic materials like Inconel, titanium, or hardened steel. That’s when I understood that the right cutting tool material wasn’t a recommendation—it was a necessity. It had to match not just the part, but the machine, the cutting conditions, and even the customer's standards. Let's explore why.

Why is it important to select proper cutting tool material during machining?

A wrong tool material leads to tool breakage, poor finish, and high rejection rates—it’s a common but avoidable mistake.

Choosing the right tool material ensures optimal performance, improves surface quality, reduces wear, and prevents unnecessary tool replacement and production delays.

In non-standard machining, the tool isn't just doing its job—it’s adapting to an unknown every time. Some materials harden when cut, some produce long chips, others react to temperature changes unpredictably. If the cutting tool material can’t handle these changes, it wears out faster, causing inconsistent tolerances or even tool failure mid-process. This not only slows production but also affects my reputation with buyers like Oliver, who expect consistent quality.

Understanding Tool Material Performance in Non-Standard Jobs

| Tool Material | Strengths | Weaknesses | Best For |

|---|---|---|---|

| High-Speed Steel (HSS) | Versatile, affordable, easy to sharpen | Low wear resistance, not for high-speed cutting | General purpose, low volume work |

| Carbide | Hard, wear-resistant, maintains shape | Brittle, expensive | Hard materials, high-speed and precise jobs |

| Ceramics | Excellent heat resistance, high-speed machining | Very brittle, not suitable for interrupted cuts | Finishing operations, heat-resistant alloys |

| CBN (Cubic Boron Nitride) | Handles hardened steels, extreme wear resistance | High cost | Hardened steels above 50 HRC |

| PCD (Polycrystalline Diamond) | Superior for non-ferrous, abrasive materials | Not for steel, expensive | Aluminum, graphite, composite machining |

The key is matching these strengths to what the job demands. For example, when my client sends me an RFQ for an aerospace bushing made from titanium, I’ll pair it with a carbide tool with proper coating, because heat buildup is a serious issue in such metals. On the other hand, for low-volume parts in mild steel, HSS might be good enough and more economical.

What are the factors to consider when choosing a cutting tool?

Ignoring tool geometry, material compatibility, and machine conditions can ruin even the best design.

Factors include the workpiece material, machining speed, desired finish, machine capacity, and production volume. All must align with the tool material.

One time, a client from Germany ordered stainless steel medical fasteners in a low-volume batch. Our machining team tried to use the same tools we use for mild steel. The tools overheated, and the finish was rough. The batch failed inspection. We switched to a coated carbide tool designed for stainless and ran at slower speeds. That solved the problem.

Let’s break this down clearly:

Key Selection Criteria for Tool Material

| Factor | Why It Matters | Example Scenario |

|---|---|---|

| Workpiece Material | Determines tool hardness and coating needs | Titanium needs carbide with heat-resistant coating |

| Machining Speed & Feed | Affects heat generation and wear | High-speed cutting benefits from ceramic or CBN |

| Tolerance and Surface Finish | Influences tool geometry and edge sharpness | Precision parts require sharp, stable tools like PCD |

| Production Volume | Guides tool life vs. cost tradeoff | High volume justifies expensive, long-life tools |

| Coolant Use & Environment | Impacts thermal management and material reactivity | Dry machining favors materials with high heat resistance |

| Machine Rigidity | Affects vibration, influencing tool choice | Lightweight machines need forgiving tools like HSS |

Matching tool material to all these aspects helps maintain quality and predictability—even when the part isn’t standard.

Why is it important to select the proper tools?

The right tool setup avoids scrapped parts, downtime, and rework, especially in small-batch or prototype runs.

Proper tools prevent failure, reduce cycle times, improve part quality, and ensure the machine and operator are working efficiently.

Non-standard parts often involve many setup changes. When each job is different, standard tools just won’t fit. The geometry might be wrong, or the tool might be too long, causing deflection. I've seen machines crash because someone used a standard-length drill in a deep hole job. That’s why tool planning is as important as the quote itself. Every dimension, clearance, and tolerance must be checked before cutting even begins.

Common Tool Selection Mistakes and How to Avoid Them

| Mistake | Consequence | Best Practice |

|---|---|---|

| Using standard tools for complex parts | Poor access, chatter, tool breakage | Use application-specific or custom tools |

| Choosing based on price alone | Frequent replacement, inconsistent results | Factor in tool life and finish quality |

| Ignoring part material hardness | Rapid wear, overheating | Choose tool based on material specs |

| Wrong tool coating | Built-up edge, poor chip evacuation | Match coating to material (e.g., TiAlN for steel) |

| No simulation or test run | Risk of machine damage or scrap | Run simulation or trial on similar material |

I keep a log of all tooling issues I’ve faced over the years. That’s helped me train new staff and troubleshoot customer feedback faster. If I quote a part that failed before, I revisit the tooling plan. No guesswork allowed.

What are the major properties required of cutting tool materials?

Not all tool materials can handle the stress of modern machining, especially with tight deadlines and complex geometries.

Cutting tool materials must offer hardness, toughness, heat resistance, wear resistance, and chemical stability to perform under high-speed, high-stress conditions.

We once machined copper-alloy components for a customer in the energy sector. The material was soft, but it built up on the tool edge fast. Our first batch failed due to a poor finish. After switching to a PCD tool with high chemical resistance, we could maintain surface finish and dimensional accuracy.

Here’s how each property affects real machining performance:

Essential Properties of Tool Materials

| Property | Definition | Why It Matters |

|---|---|---|

| Hardness | Resistance to deformation under cutting pressure | Ensures edge holds sharpness during cutting |

| Toughness | Ability to resist chipping and breaking | Important for interrupted cuts and high-feed operations |

| Heat Resistance | Withstands high temperatures during machining | Prevents softening and loss of hardness at high speeds |

| Wear Resistance | Resists gradual material loss during operation | Determines how long a tool lasts and maintains accuracy |

| Chemical Stability | Resists reaction with workpiece materials | Reduces built-up edge and protects tool surface integrity |

Each application prioritizes one or two of these. For non-standard aerospace parts, we often prioritize heat resistance and toughness. For aluminum parts in high volume, we look for wear resistance and chemical stability.

Conclusion

Non-standard parts machining needs tool materials chosen with precision. The wrong choice costs time, money, and credibility.