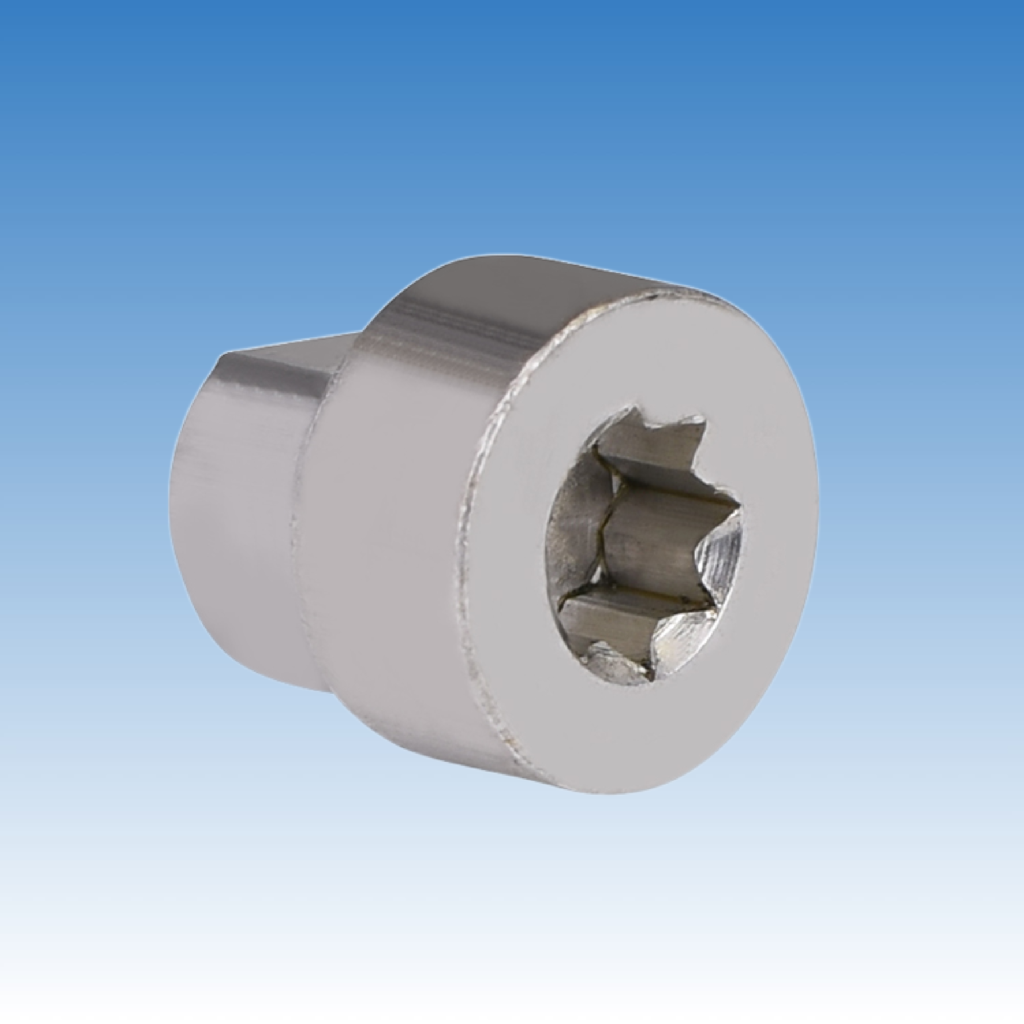

When manufacturing cold formed parts, small defects can lead to major failures. That is why understanding defect standards like ISO 6157 is critical for both buyers and suppliers.

ISO 6157 defines defects in cold formed parts as deviations from intended form, fit, or function, ensuring clear quality standards for automotive, electronics, and aerospace industries.

Clear quality definitions keep projects on track and reduce the risk of costly disputes. I learned early that buyers like Oliver Smith expect a consistent understanding of defects across all suppliers. Let me walk you through the key points you need to know about ISO 6157.

What is the ISO definition of defect?

Small defects often seem harmless. But for buyers like Oliver, they mean risk. ISO 6157 makes sure we are speaking the same language.

ISO defines a defect as any deviation in a cold formed part that reduces its ability to meet drawing specifications or functional requirements, including appearance issues.

Diving deeper: Understanding ISO's Defect Scope

ISO 6157 splits defects into two big types: critical and minor. Critical defects are those that can cause a failure in application. Minor ones only affect the surface look but not the function. Here's a basic table to help you see the difference:

| Type of Defect | Description | Example |

|---|---|---|

| Critical | Affects part function | Crack, dimension out of tolerance |

| Minor | Affects appearance only | Surface dent, light discoloration |

In my experience, German buyers often tolerate minor defects if parts meet function. But they are strict about critical defects. ISO 6157 even outlines "acceptance conditions," like how many minor defects are allowed per batch. This clarity avoids arguments later.

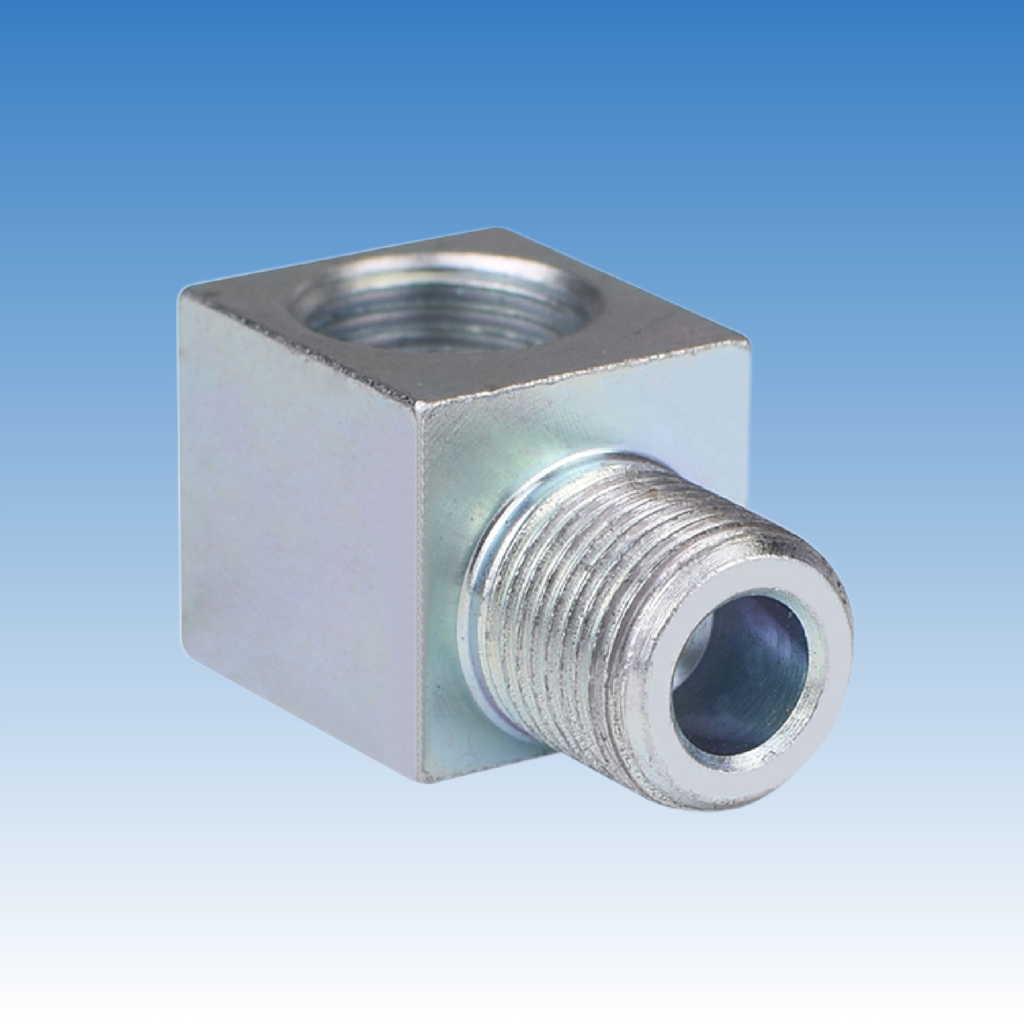

What are the defects in cold rolled steel?

Even with top materials, defects happen. Understanding them early saves time and money for everyone.

Cold rolled steel defects include surface cracks, edge waves, center buckles, oil stains, and uneven thickness caused by poor rolling processes.

Diving deeper: Common Cold Rolled Steel Defects

Each defect in cold rolled steel comes from a specific root cause. Here's a quick guide to help you spot them:

| Defect Type | Cause | Impact |

|---|---|---|

| Surface cracks | Excessive rolling pressure | Weakens strength |

| Edge wave | Uneven tension during rolling | Poor fitting |

| Center buckle | Improper roller adjustment | Warping |

| Oil stains | Poor maintenance during rolling | Appearance issue |

| Thickness variation | Fluctuation in rolling speed | Tolerance failure |

When I worked with a German distributor last year, we rejected an entire lot because of center buckle issues that made assembly impossible. It is always better to catch these defects before parts ship out.

What are the defects of cold extrusion?

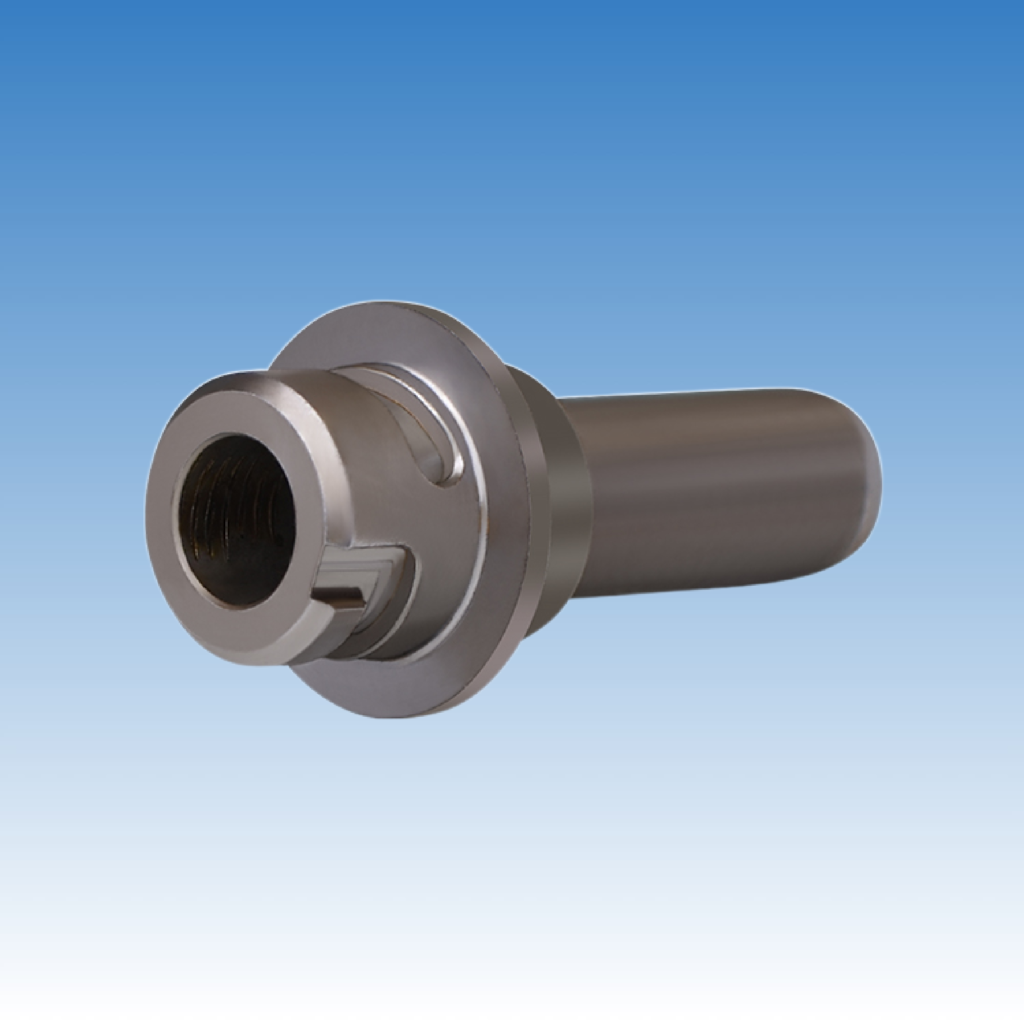

Cold extrusion pushes metal into a die. It saves material and adds strength. But it also brings new risks if not done right.

Cold extrusion defects include incomplete filling, surface cracks, fold lines, die marks, and internal stresses that can lead to cracking later.

Diving deeper: Key Defects in Cold Extrusion

Extrusion needs precise control of material flow. If not, defects will show up. Here's a simple breakdown:

| Defect | Cause | Impact |

|---|---|---|

| Incomplete filling | Material flow too slow or blocked | Weak or missing areas |

| Surface cracks | Excessive pressure or poor lubrication | Part failure |

| Fold lines | Improper die design | Stress concentration |

| Die marks | Dirty or damaged die | Surface finish issue |

| Internal cracks | Rapid or uneven deformation | Hidden failure risks |

Once, a customer found fold lines on cold extruded sleeves we supplied. We traced it back to a slight die misalignment. After fixing it, our rejection rate dropped by 40%.

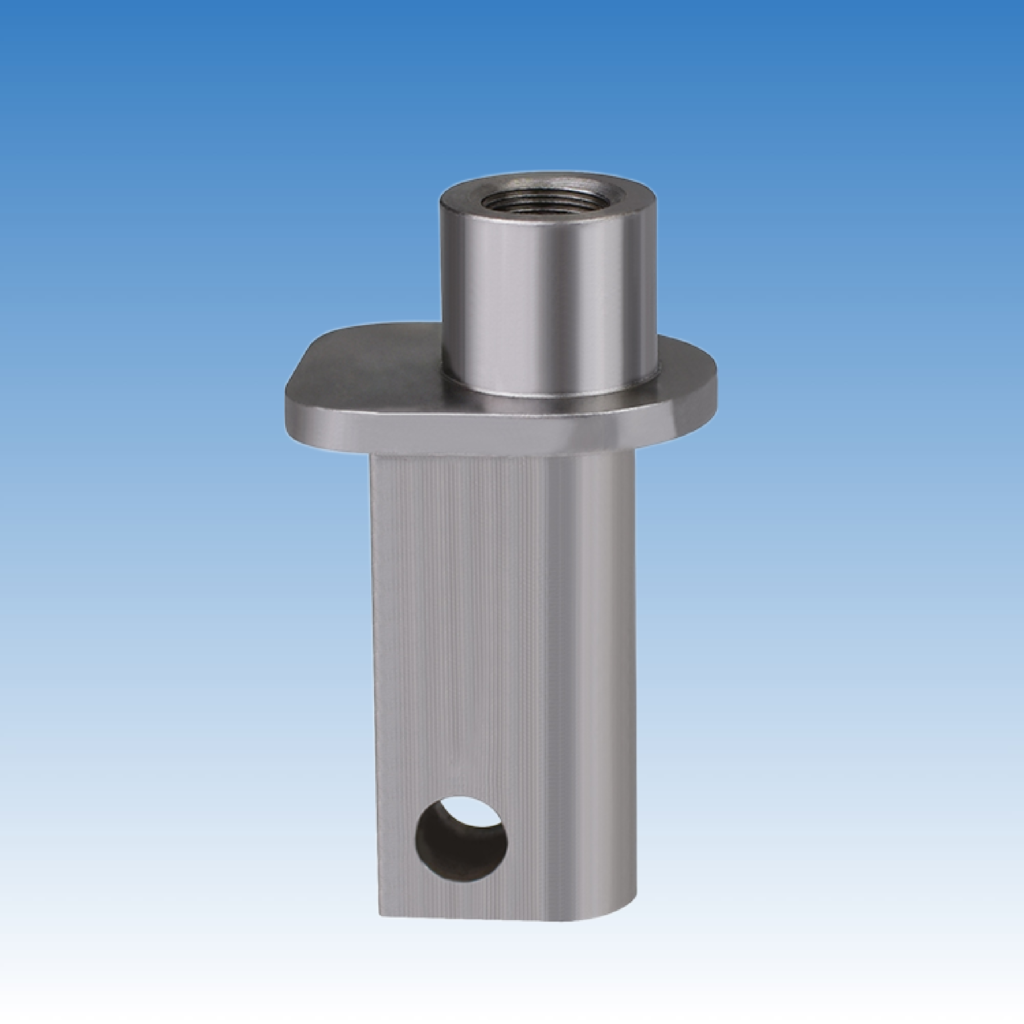

How to avoid defects in cold formed parts?

Knowing the causes of defects is half the battle. Avoiding them is the other half, and it takes discipline every step of the way.

To avoid defects in cold formed parts, manufacturers must control raw material quality, optimize forming processes, maintain clean dies, and use regular inspections to catch issues early.

Diving deeper: Steps to Minimize Defects

I often remind my team that defect prevention starts long before production. It begins with good raw material and tight process control. Here's how we do it:

| Step | Action | Reason |

|---|---|---|

| Raw Material Inspection | Check chemical composition, hardness, and surface | Only good input can give good output |

| Die Maintenance | Regular cleaning and polishing | Prevents surface marks and uneven flow |

| Process Monitoring | Control temperature, pressure, and speed | Keeps deformation uniform |

| In-Process Inspection | Visual and dimensional checks at key points | Catch defects before they spread |

| Training Operators | Teach best practices and defect identification | Reduces human error |

A big buyer once shared that many suppliers skip in-process checks. They rely only on final inspection. But by then, it is too late. Prevention must happen early and often.

Conclusion

ISO 6157 gives us a clear, shared language for defects in cold formed parts, helping avoid misunderstandings, saving time, and protecting our reputations.