Choosing between machined aluminum and cast aluminum can feel confusing—both sound strong, precise, and efficient, but they suit very different project needs.

Machined aluminum offers higher precision and strength, while cast aluminum is better for complex shapes and lower costs. The best choice depends on your design, budget, and end-use.

When sourcing aluminum parts for your project, it’s easy to get stuck between two popular options—machined and cast. They both seem reliable. But what you really need is clarity. So let's compare these two materials in detail and figure out which one fits your project better.

What Is Machined Aluminum and When Should You Use It?

Machined aluminum sounds high-tech, but is it always the better choice?

Machined aluminum is ideal for high-precision parts with tight tolerances, excellent surface finishes, and strong mechanical properties.

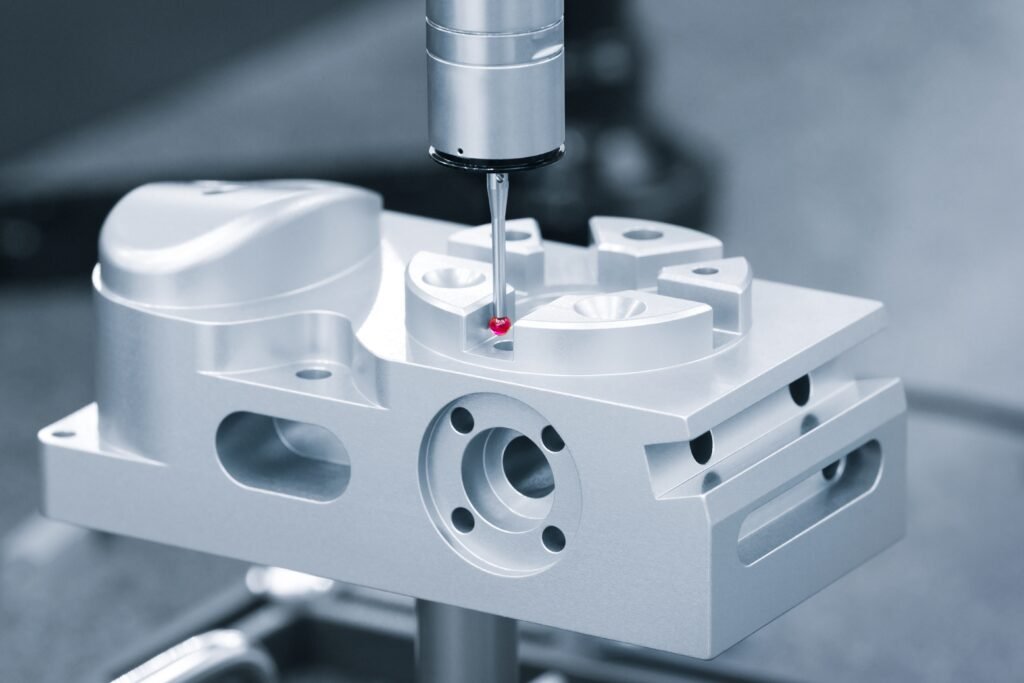

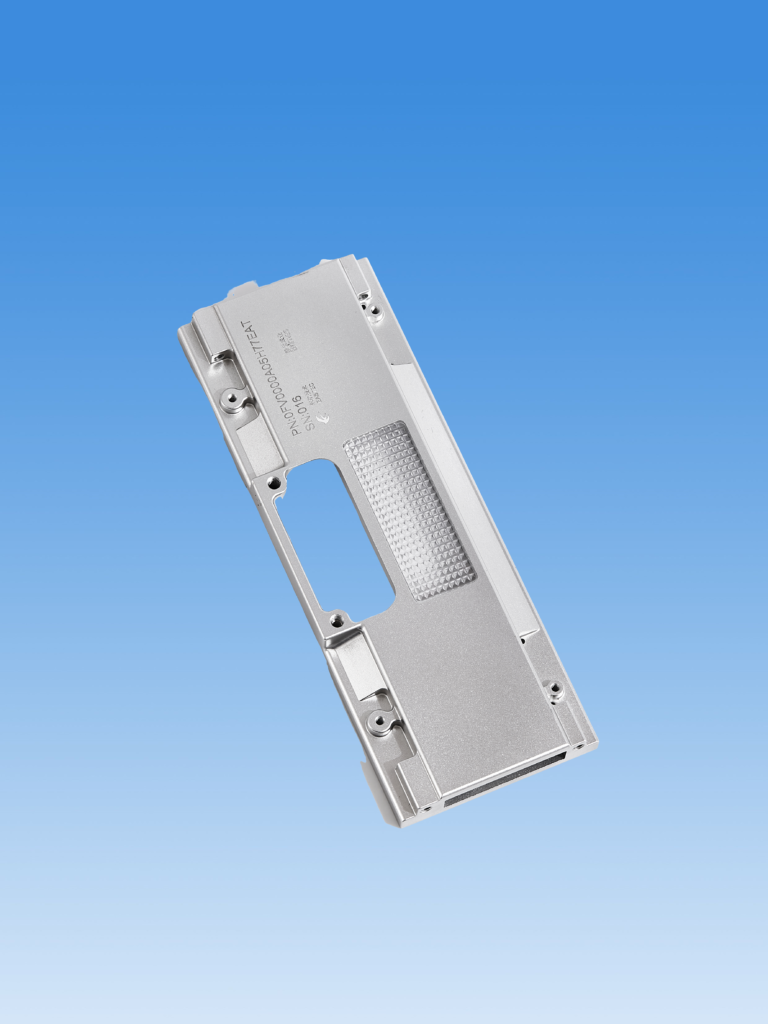

Machined aluminum parts are made by removing material from a solid aluminum block using CNC machines. This gives great accuracy. It’s especially useful for components that need to fit perfectly—like parts inside machines, engines, or electronic enclosures.

Here's a breakdown of the main advantages and trade-offs:

| Feature | Machined Aluminum |

|---|---|

| Strength | Very high due to solid billet structure |

| Tolerance | Extremely tight |

| Surface Finish | Excellent |

| Cost | Higher per piece |

| Suitable for Complex Shapes | Not as much (depends on machining limits) |

If your project needs strength, precision, and a clean look, machined aluminum works better. But if you're making thousands of parts and the design is complicated, it can get expensive quickly.

What About Cast Aluminum? Is It More Cost-Effective?

Cast aluminum seems simpler, but is it the smarter choice for production?

Cast aluminum is best for complex shapes and large volumes where slightly lower strength is acceptable, and lower costs are critical.

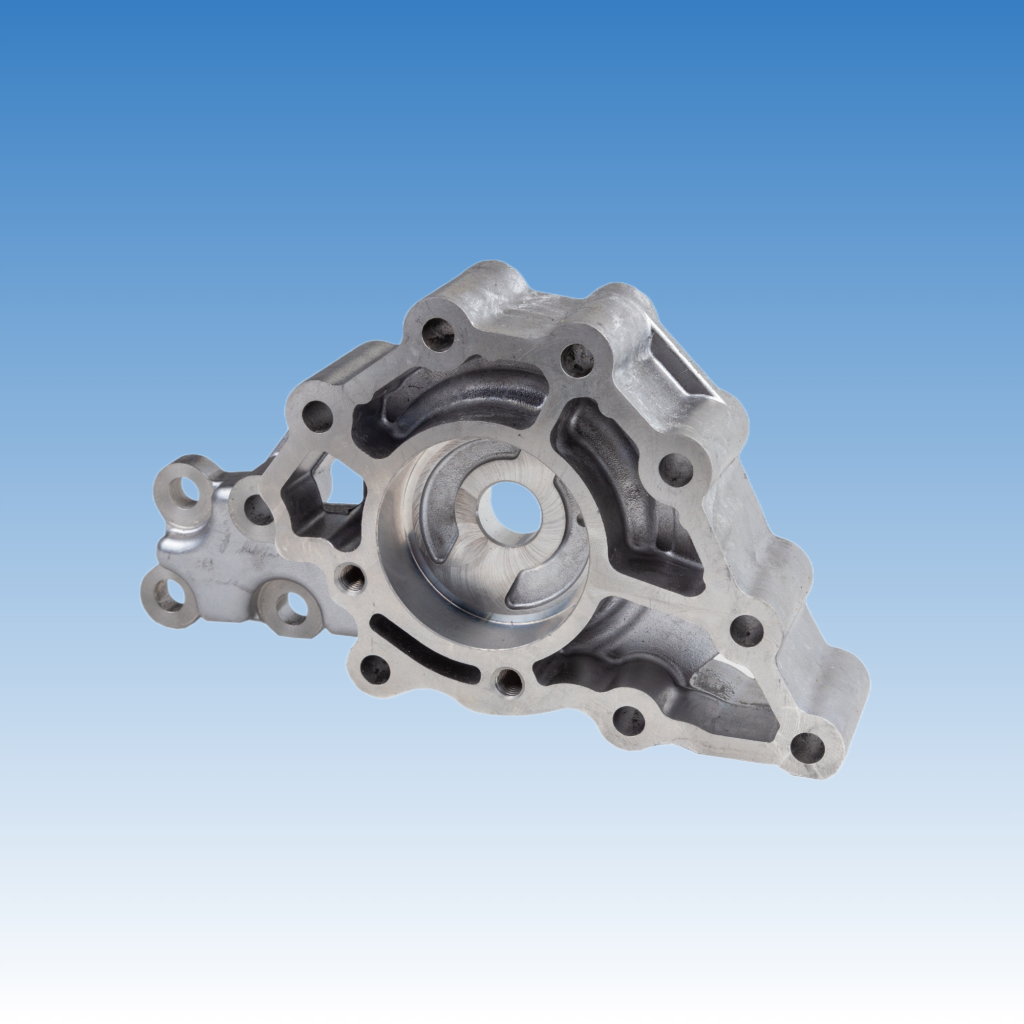

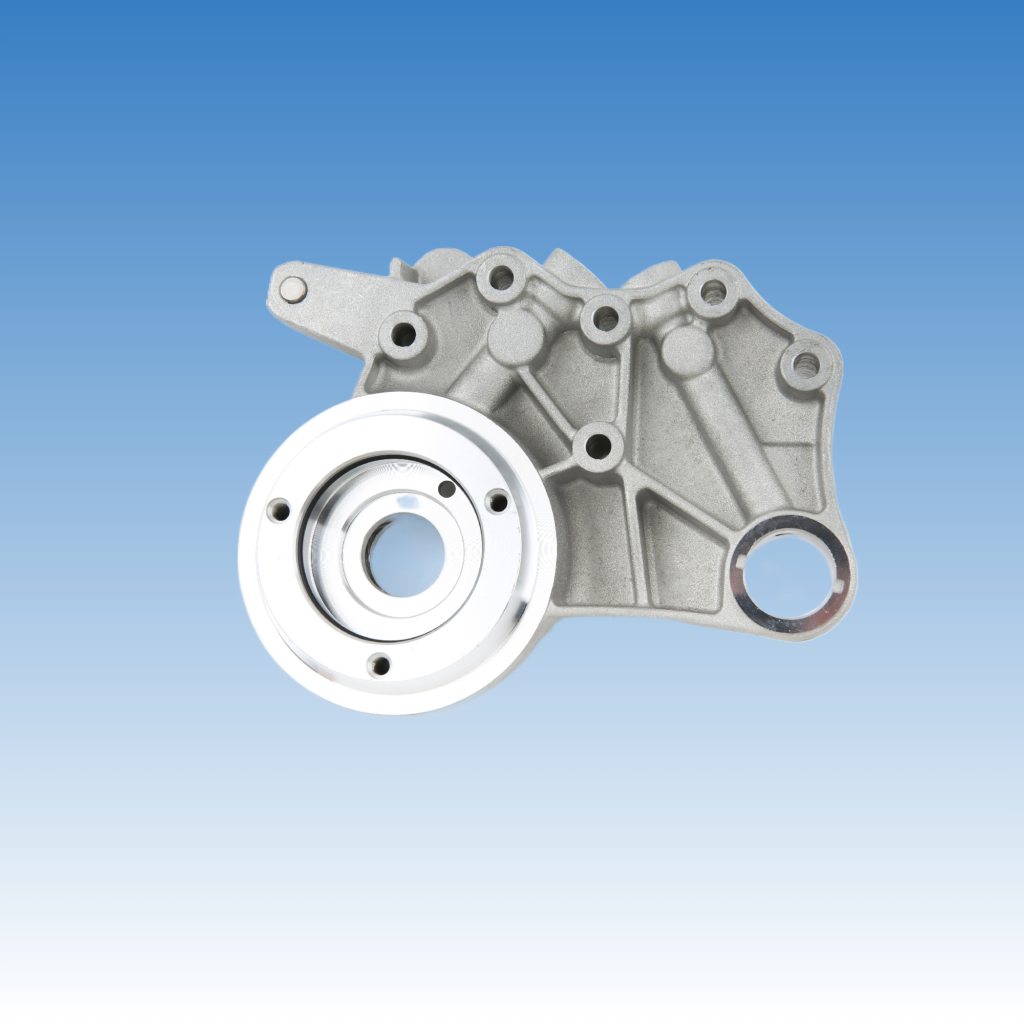

Cast aluminum is produced by pouring molten metal into a mold. This allows for very detailed shapes, including hollow sections and curves. It’s widely used in automotive housings, cookware, and structural parts.

Let’s compare:

| Feature | Cast Aluminum |

|---|---|

| Strength | Lower than machined |

| Tolerance | Moderate |

| Surface Finish | Rougher, needs post-processing |

| Cost | Lower for high volume |

| Suitable for Complex Shapes | Very suitable (complex molds possible) |

If your part design is hard to machine or you’re producing thousands of units, casting is more economical. But it comes with trade-offs in strength and finish.

How Do I Choose Between Them Based on My Industry?

You might wonder: which one fits better in automotive, medical, or machinery parts?

Choose machined aluminum for industries that need high accuracy and performance. Choose cast aluminum for industries that focus on volume and cost-efficiency.

Every industry values something slightly different. Here’s a quick table showing typical usage:

| Industry | Preferred Type | Reason |

|---|---|---|

| Automotive | Both (cast for engine blocks, machined for precision parts) | Cost vs. precision balance |

| Medical | Machined | Hygiene, strength, and tight tolerances |

| Aerospace | Machined | Performance and strict quality requirements |

| Electronics | Machined | Housing and thermal performance |

| General Machinery | Cast | Volume production, general-use parts |

Think about what matters more: precision or volume. For example, a German client I worked with needed connector housings for industrial control panels. We used machined aluminum to ensure every piece met their exact technical drawing.

What Are the Main Trade-Offs to Consider?

You want to avoid making the wrong choice and wasting budget—so what are the key trade-offs?

The decision comes down to a trade-off between precision and production cost. Machined parts offer tighter control. Cast parts offer better value at volume.

Here are a few things to consider:

- Design complexity: Cast aluminum handles curves and hollows better.

- Volume: High-volume orders usually favor casting.

- Post-processing: Machined parts need less finishing.

- Certification: Machined parts are easier to inspect and certify.

Think about your sourcing pain points too. If your supplier often delays or lacks consistency, you may prefer machined parts with better quality control.

Conclusion

Choosing between machined and cast aluminum is about balancing precision, strength, and cost—match your material to your project’s real needs.