Most problems with fastener fit come from misunderstanding threads—using the wrong type causes delays, returns, or worse, machine failures.

The four main types of threads used on fasteners are UNC, UNF, metric, and BSP. Each has different standards, measurements, and use cases.

Misunderstanding thread types can cause parts to fail, deliveries to be delayed, and customers to be lost. I’ve dealt with buyers who didn’t know the difference between UNF and BSP and had machines break as a result. Let’s clear this up.

What is the most common thread type used for most fastener applications?

Thread confusion creates more problems than you'd think—it seems small, but it can halt a whole assembly line.

Metric threads are the most common worldwide due to ISO standardization, especially in automotive, electronics, and machinery industries.

Metric threads are defined by the International Organization for Standardization (ISO). That’s why they are dominant across Europe and Asia, and are found in more than 70% of machinery exported from China. UNC and UNF threads are mostly used in the US market, while BSP is more common in fluid systems. The metric thread is versatile, used in bolts, screws, and precision parts. Its diameter and pitch are easy to calculate and fit a wide range of standard gauges. For B2B buyers like Oliver, using metric threads helps reduce variation in inventory and lowers the risk of wrong purchases.

| Thread Type | Standard | Typical Use | Region |

|---|---|---|---|

| Metric | ISO | Automotive, electronics | Global |

| UNC | ASME | General-purpose, coarse pitch | USA |

| UNF | ASME | Fine-thread precision parts | USA |

| BSP | British Std. | Fluid/gas fittings | UK, Asia |

What is g and h in thread?

Buyers often get confused when they see “M12x1.25-6g” or “M10x1.0-6h” on drawings. Let’s break that down.

The “g” and “h” in metric threads refer to the tolerance position for external and internal threads. They define the fit between mating parts.

In metric threads, lowercase letters like “g” and “h” are used for external threads (on bolts), while uppercase letters like “G” and “H” are for internal threads (in nuts or tapped holes). The number before the letter, such as “6g,” refers to the tolerance grade. Most standard bolts use “6g.” If a customer sends me a drawing with “6h,” I know it’s likely an internal thread and that the fit will be tighter.

| Symbol | Location | Description |

|---|---|---|

| g | External | Loose to medium tolerance |

| h | External | Tight tolerance fit |

| G | Internal | Medium to loose tolerance |

| H | Internal | Tight tolerance fit |

The right tolerance ensures the screw fits well—too loose, and it falls out; too tight, and it jams or breaks during assembly. Buyers need to match these to function, and we always confirm this before production.

How to identify thread types?

Wrong threads cause chaos—nothing fits, assembly stalls, and returns pile up. Let’s make it easy to identify them.

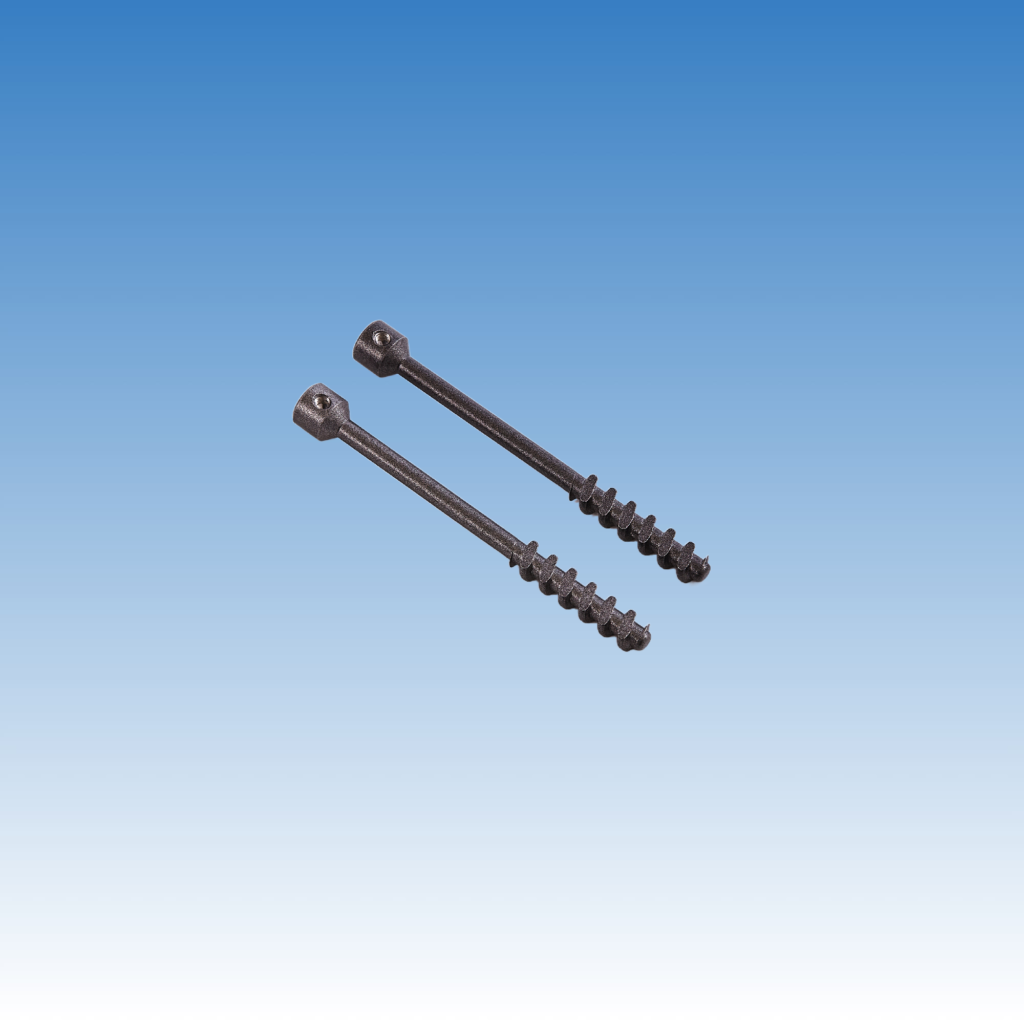

You can identify thread types by checking the pitch, angle, diameter, and profile shape using a thread gauge or caliper.

When buyers send samples with no documentation, the first thing we do is check if the thread is metric or inch-based. Metric threads use pitch (distance between threads in mm), while inch threads use threads per inch (TPI). UNC and UNF threads are both 60-degree angles, but UNF is finer. BSP threads can be parallel or tapered and often have a 55-degree angle.

To identify accurately:

- Use a caliper to measure the outer diameter.

- Use a thread gauge to measure pitch or TPI.

- Check the thread angle with templates or compare under a microscope if needed.

- Match with standard tables to confirm.

| Feature | Metric | UNC/UNF | BSP |

|---|---|---|---|

| Pitch | mm (e.g., 1.25) | TPI (e.g., 20) | TPI (e.g., 14) |

| Thread angle | 60° | 60° | 55° |

| Application | Machinery | General Fasteners | Pipes/Fittings |

I’ve had customers send me fasteners they thought were BSP but turned out to be NPT. That’s a costly mistake, especially in fluid systems where leaks can be dangerous.

Are BSP and ISO threads the same?

A common trap for overseas buyers is assuming British and ISO standards are interchangeable. They’re not.

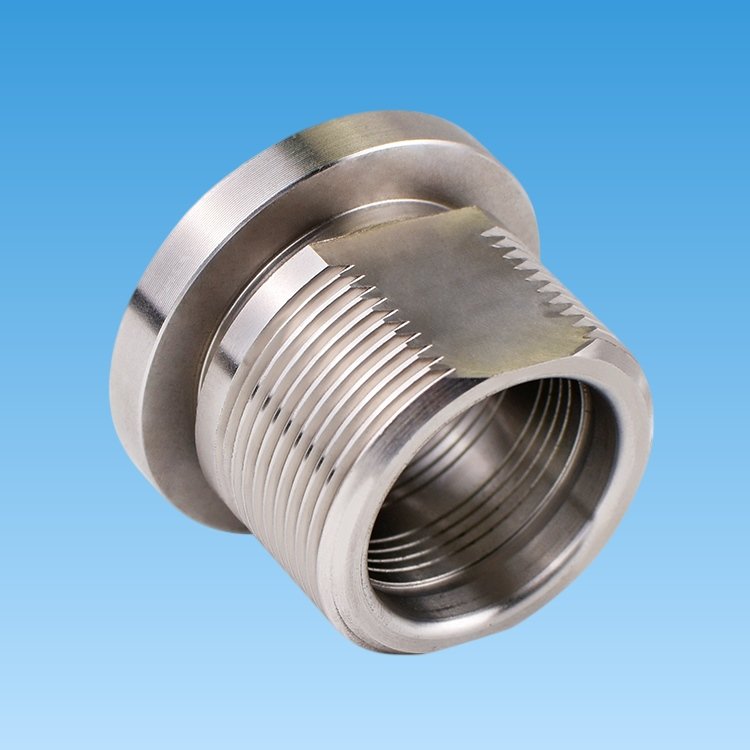

BSP and ISO threads are not the same. BSP threads use a different angle and form compared to ISO metric threads and are used for different applications.

BSP stands for British Standard Pipe. It is mainly used in plumbing and fluid systems. BSP threads come in two types: BSPP (parallel) and BSPT (tapered). ISO metric threads, on the other hand, are for mechanical fasteners and are not designed to seal fluid under pressure.

ISO metric threads follow a 60-degree flank angle. BSP uses a 55-degree angle. Their diameters and pitch values can look similar but are not compatible. A BSP thread will not seal properly in an ISO tapped hole, even if it feels like it fits.

| Feature | BSPP/BSPT | ISO Metric |

|---|---|---|

| Angle | 55° | 60° |

| Use | Pipes, fluids | General fasteners |

| Sealing method | Threads + sealant | Fit/washer |

| Compatibility | Not interchangeable | Not interchangeable |

When sourcing from China, I always double-confirm thread standards with buyers. I’ve seen orders returned because the customer asked for BSP but assumed they were metric. Confirming this early avoids weeks of delay and saves shipping costs.

Conclusion

There are four main thread types—metric, UNC, UNF, and BSP—and knowing the difference helps avoid costly errors in sourcing and production.