When choosing stainless steel fasteners, picking the wrong grade can mean wasted money or product failure.

Stainless steel 304 is used more widely for general applications, while 316 is chosen for its superior corrosion resistance in harsher environments, especially near saltwater or chemicals.

Both 304 and 316 are austenitic stainless steels. But they don’t perform the same way in all environments. The extra element in 316—molybdenum—makes a big difference in real-world applications. Let’s look deeper into how that changes performance, cost, and usage.

What are the disadvantages of 316 stainless steel?

If 316 is stronger, why not always use it? There's a reason.

The biggest disadvantage of 316 stainless steel is its higher cost, which can be over 20% more than 304, without being necessary for every use.

Why price and machinability matter in fasteners

Fasteners are often used in large quantities. When production volume is high, even a small price difference adds up. That’s why many buyers still prefer 304 stainless steel. It balances corrosion resistance and cost.

Here’s a simple table comparing the two in fastener applications:

| Property | Stainless Steel 304 | Stainless Steel 316 |

|---|---|---|

| Corrosion resistance | Good | Excellent (with molybdenum) |

| Cost | Lower | Higher |

| Machinability | Better | Slightly harder to machine |

| Strength | Similar | Similar |

| Resistance to chlorides | Poor | Excellent |

For many mechanical uses where there’s no salt or chemicals, 304 works just fine. Using 316 would only raise the cost. Also, in my own experience with machining centers, 316 sometimes wears out tools faster. This increases downtime and tool costs.

How to distinguish 304 from 316?

You can’t tell the difference just by looking. But with a little testing, you can know for sure.

304 and 316 look the same, but 316 has molybdenum, which can be detected by chemical testing or marked certificates from reliable suppliers.

Testing methods that actually work

There are a few ways to check the difference:

| Method | Accuracy | Cost | Comment |

|---|---|---|---|

| Moly Drop Test | High | Low | Drops turn color with molybdenum |

| XRF Analyzer (Portable) | Very High | High | Used in advanced quality labs |

| Material Certificate | High (if genuine) | Free with purchase | Only reliable from trustworthy suppliers |

In our exports to Europe, especially Germany, clients often request original certificates with full chemical breakdowns. One buyer, Oliver Smith, once returned a shipment because a local lab test revealed the "316" bolts were actually 304. That’s why I always stress accurate material labeling.

Where is 304 stainless steel used?

304 is the workhorse of stainless steels. It’s everywhere.

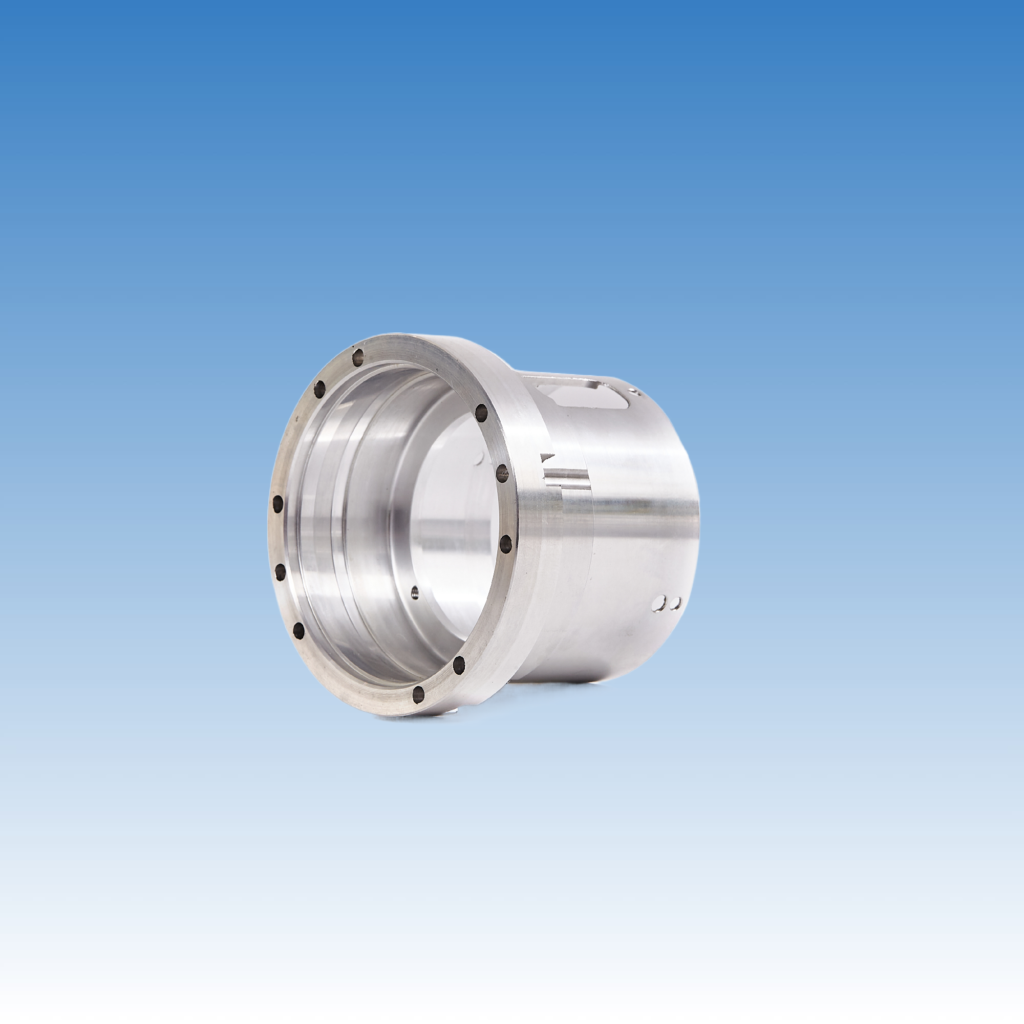

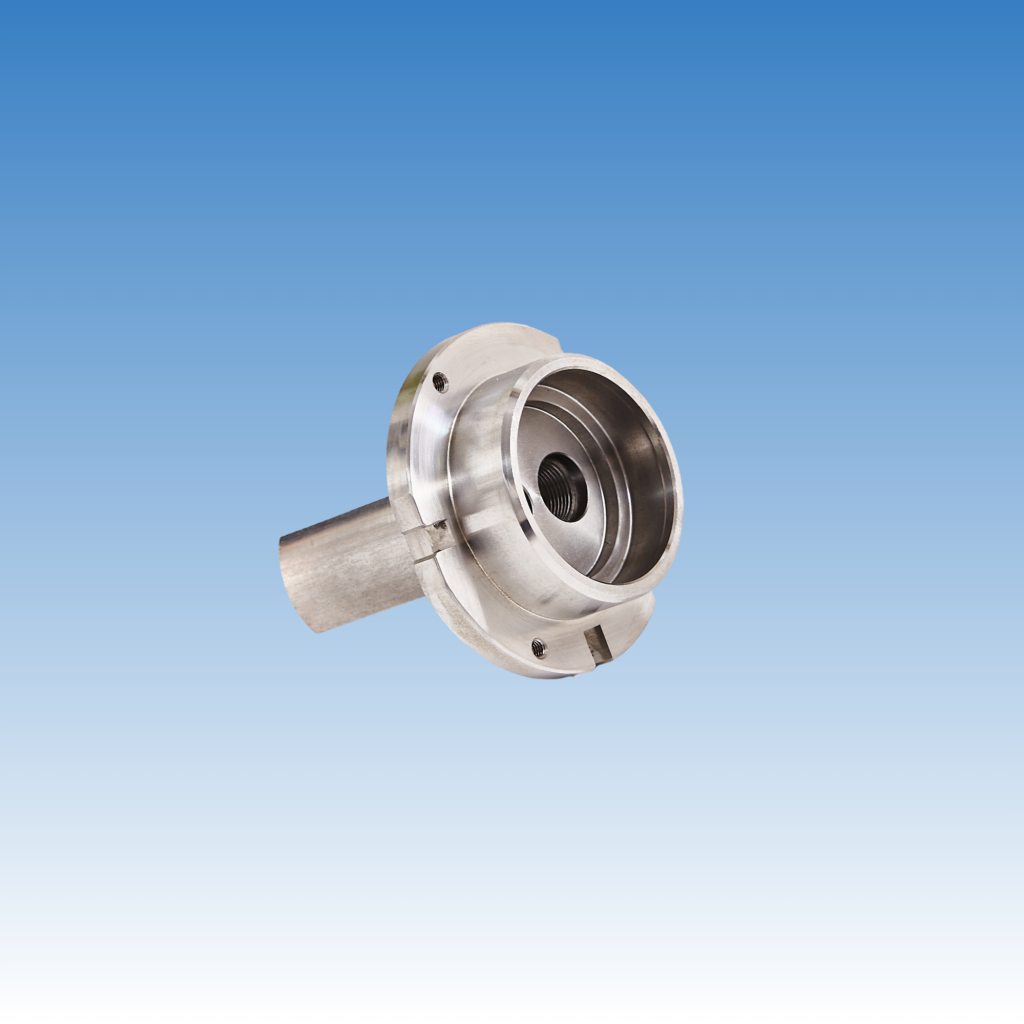

304 stainless steel is widely used in fasteners for machinery, construction, household items, and mild outdoor environments due to its solid corrosion resistance and affordability.

Why 304 remains the top choice

Here’s where 304 fasteners are commonly used:

| Industry | Application | Reason for Use |

|---|---|---|

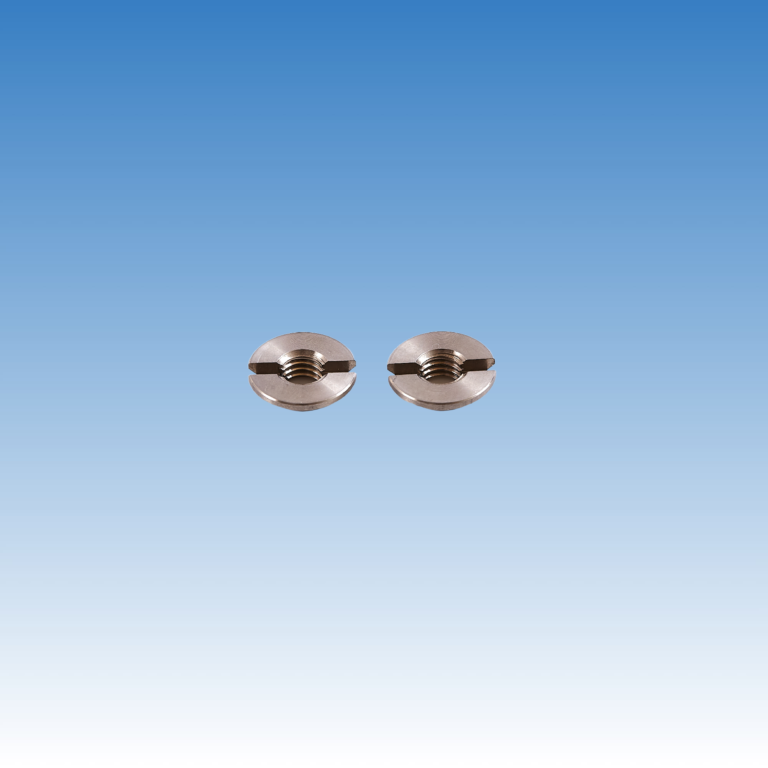

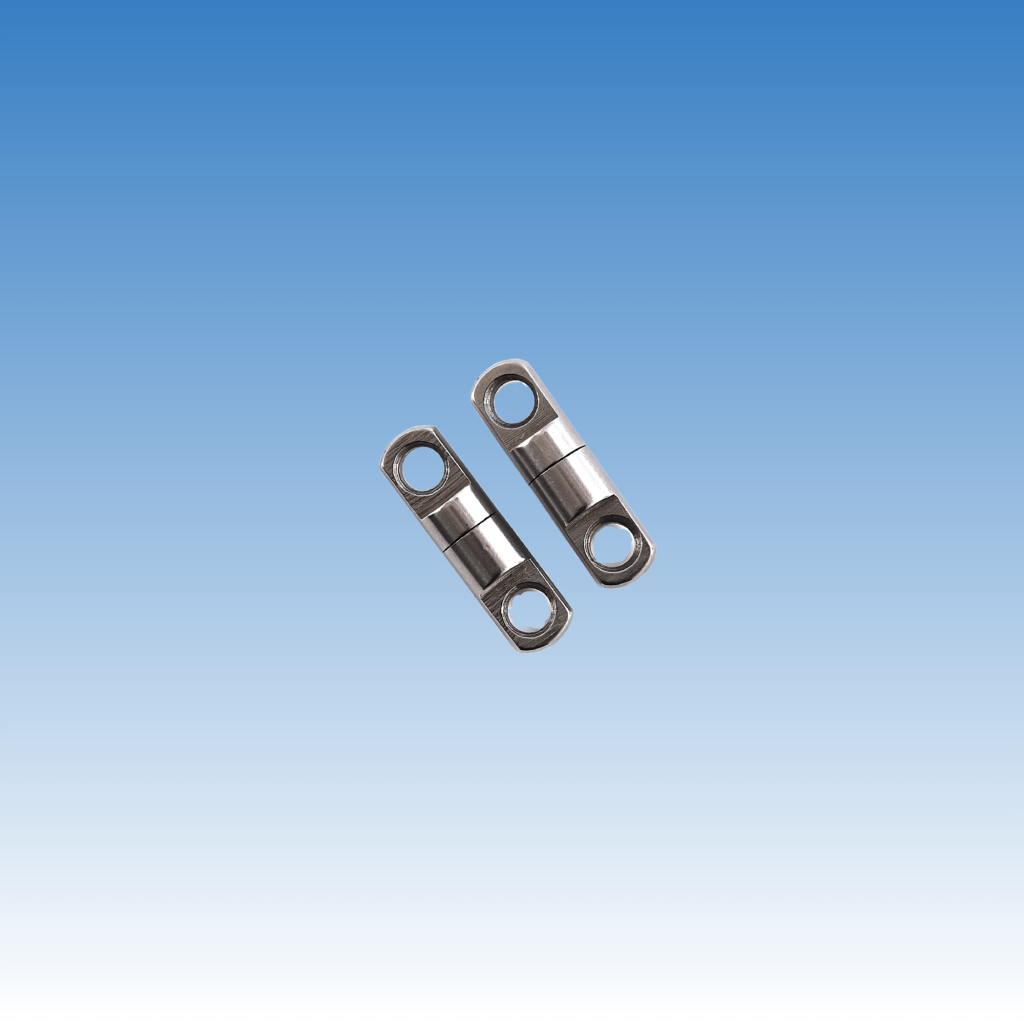

| Machinery | General bolts and nuts | Balanced cost and strength |

| Construction | Handrails, framing screws | Good appearance, rust resistance |

| Automotive | Engine covers, brackets | Heat and wear resistant |

| Appliances | Ovens, fridges, dishwashers | Hygienic and stain-resistant |

I’ve shipped thousands of 304 parts for these industries. Clients rarely have problems unless they install them in coastal or chemical environments. In those cases, 316 would’ve been the smarter choice.

Is stainless steel 304 or 316 for food?

Food safety is non-negotiable. The right choice avoids contamination.

Both 304 and 316 are food-safe, but 316 is often preferred in high-salt or acidic food environments like meat processing or seafood due to better corrosion resistance.

Choosing food-safe fasteners for processing equipment

In food production, cleanliness is key. Even a small crack or pit in a fastener can harbor bacteria. 304 is common in kitchens and food machines. But if there are chlorides or acids involved, 316 is safer.

| Food Environment | Recommended Steel | Why |

|---|---|---|

| General kitchens | 304 | Affordable and safe |

| Meat or fish processing | 316 | Resists blood acids and salt |

| Beverage industry | 304 or 316 | Depends on acidity of the drinks |

| Canning or pickling | 316 | Better against acidic liquids |

Some years ago, a client producing industrial mixers in France upgraded to 316 after customers reported rusting bolts. Since then, zero complaints. The cost went up slightly, but customer satisfaction made it worth it.

Conclusion

304 is cost-effective and versatile, but 316 offers extra protection in harsh environments like marine, chemical, or food processing industries.