Tapping seems simple. But in high-precision machining, one small mistake can scrap a whole batch. Are you really avoiding the hidden traps in tapping?

The most common problems in precision tapping are oversized threads, broken taps, misalignment, stuck threads, and surface burrs. These issues often come from poor setup, tool wear, or wrong tapping conditions.

Many buyers I work with believe tapping is just the last step after drilling. But in reality, tapping is where most errors in high-tolerance parts happen. When you’re supplying parts to automotive or medical companies, a single thread issue can trigger rejections or worse. Let's look at the root of each issue and how I handle them.

What causes oversized threads in a hole?

Oversized threads can ruin fit and sealing. It’s a small defect that leads to big failures. Why does this happen so often?

Oversized threads usually happen due to worn taps, oversized drilled holes, or wrong tapping parameters like low feed rates or wrong thread pitch.

I’ve seen this most often when the drill hole is already too large. Many buyers from Germany ask for H7 tolerance holes, then tap an M6 or M8 thread inside. But if the drilling step isn't checked tightly, the final thread is loose. Here’s how I break it down:

Causes of Oversized Threads

| Cause | Description |

|---|---|

| Worn tap | The tap has lost its sharpness and can't form clean threads. |

| Oversized pilot hole | A hole drilled too large makes threads shallow or incomplete. |

| Low feed rate or speed | Improper tapping parameters reduce cutting action. |

| Wrong tap class | Using a general tap instead of a class fit tap causes deviations. |

Using calibrated gauges after tapping helps catch this. But by then, the part is done. I always insist on checking the pilot hole diameter and replacing taps regularly, especially on stainless steel parts.

What causes stuck threads?

Ever tried to screw a bolt and it suddenly jams halfway? That’s a stuck thread. It’s more than annoying—it damages the part and the tool.

Stuck threads come from poor chip evacuation, tap misalignment, or contamination inside the hole during tapping.

I often get parts from suppliers that look fine at first glance, but when you test the thread, it sticks or binds. That’s usually from one of three things: the tap wasn’t aligned, the chips weren’t cleared, or something was inside the hole. Here's a deeper breakdown.

Common Triggers of Stuck Threads

| Cause | Explanation |

|---|---|

| Chip buildup | No chip removal leads to jamming and galling. |

| Misaligned tap | The thread isn’t cut cleanly and causes binding. |

| Dirty holes | Leftover coolant or burrs cause tight spots. |

| Wrong lubricant | Not using the right oil for the material causes heat and binding. |

For Swiss-type parts, I recommend spiral-flute taps with through-hole oiling. And always blow the hole clean before tapping. German buyers especially expect threads to be smooth and easy to turn.

What is the correct sequence for tapping?

Many shops get the sequence wrong. That’s how even good machines make bad threads. What is the correct tapping order?

The right tapping sequence is: drill the correct size hole, deburr the hole edges, clean the hole, apply lubricant, align the tap properly, and tap with the correct speed and feed.

I remember an old batch of aluminum parts that came back from the coater with ruined threads. The reason? The shop tapped before cleaning or deburring. So the threads picked up burrs and oxide, and then seized during assembly.

Recommended Tapping Sequence

| Step | Action | Why it Matters |

|---|---|---|

| 1 | Drill to proper core diameter | Sets base for clean threads |

| 2 | Deburr entry and exit | Prevents burrs from jamming the tap |

| 3 | Clean hole | Removes dust, chips, coolant |

| 4 | Apply suitable lubricant | Reduces wear and friction |

| 5 | Align tap with axis | Ensures straight threading |

| 6 | Tap at controlled speed/feed | Balances cutting and chip removal |

When I visit our suppliers, I always double-check their tapping setup. Even one shortcut can mean 100 rejected parts.

What precautions should be taken during tapping?

Tapping can go wrong fast. One crack, one stuck tap, and the whole part is gone. What can we do to stop that?

To avoid problems during tapping, use sharp tools, control the tapping depth, ensure proper alignment, and monitor for tool wear. Coolant type and chip evacuation are also critical.

One of the worst things I’ve seen is a tap breaking inside a titanium part. It wasn’t the operator’s fault—it was the fourth tap used that day and it wasn’t changed in time. Tool life is easy to forget. But it costs more in the long run when things go wrong.

Tapping Best Practices

| Tip | Why It Helps |

|---|---|

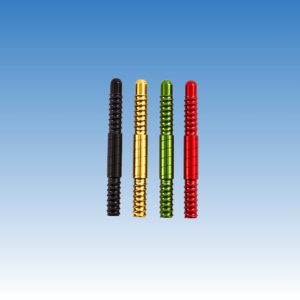

| Use high-quality taps | Reduces breakage and improves finish |

| Replace taps regularly | Prevents size deviations and chipping |

| Use tapping oil or coolant1 | Extends tool life and improves chip flow |

| Keep the hole clean | Avoids jammed or damaged threads |

| Align tool precisely | Prevents cross-threading |

| Control depth with stops | Ensures threads aren’t too shallow or deep |

I also recommend logging tap usage2 and scheduling replacements. Especially on long production runs, that makes a big difference.

Conclusion

Precision tapping isn’t just about making threads—it’s about preventing tiny issues that cause big problems. Stick to the basics, and control every step.