How Is the ISO 2320 Standard for Prevailing Torque Testing Applied in Fastener Performance?

When it comes to fasteners, performance is everything. If the torque is not right, the product could fail, leading to costly problems for everyone involved.

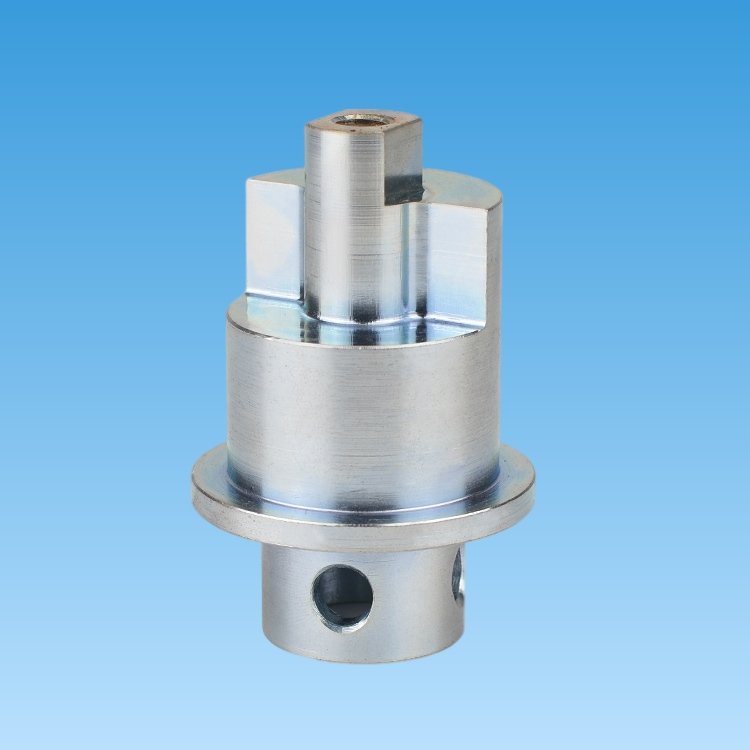

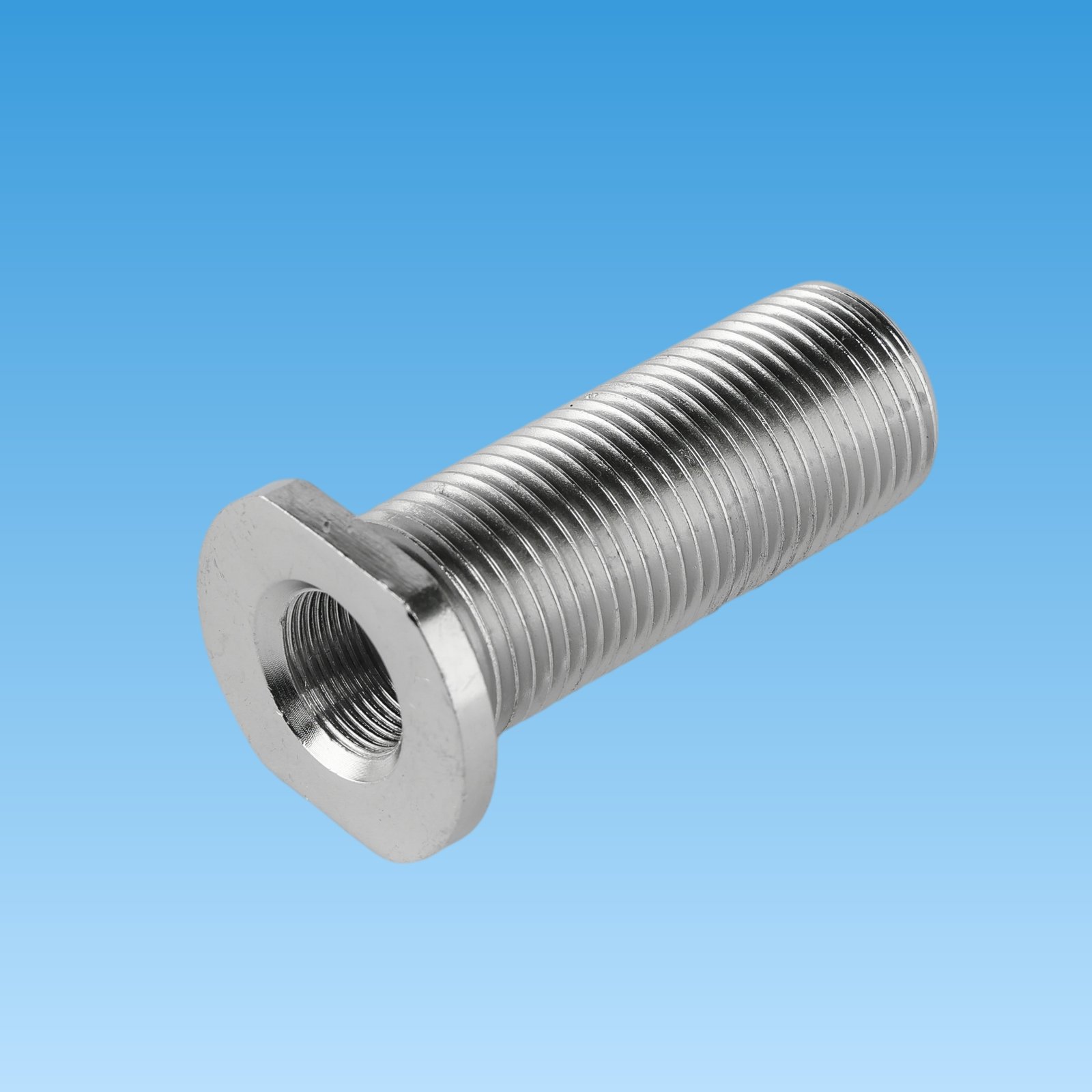

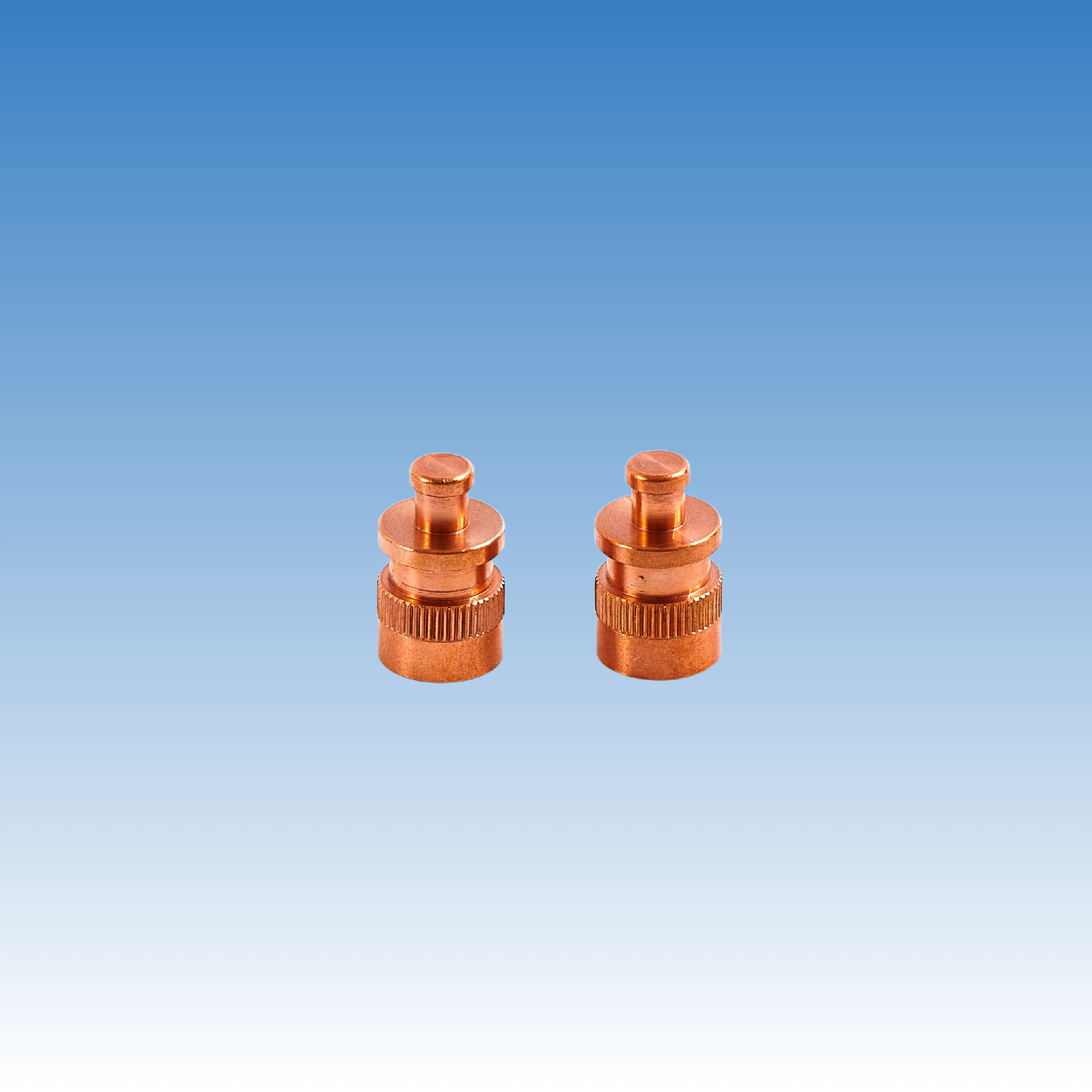

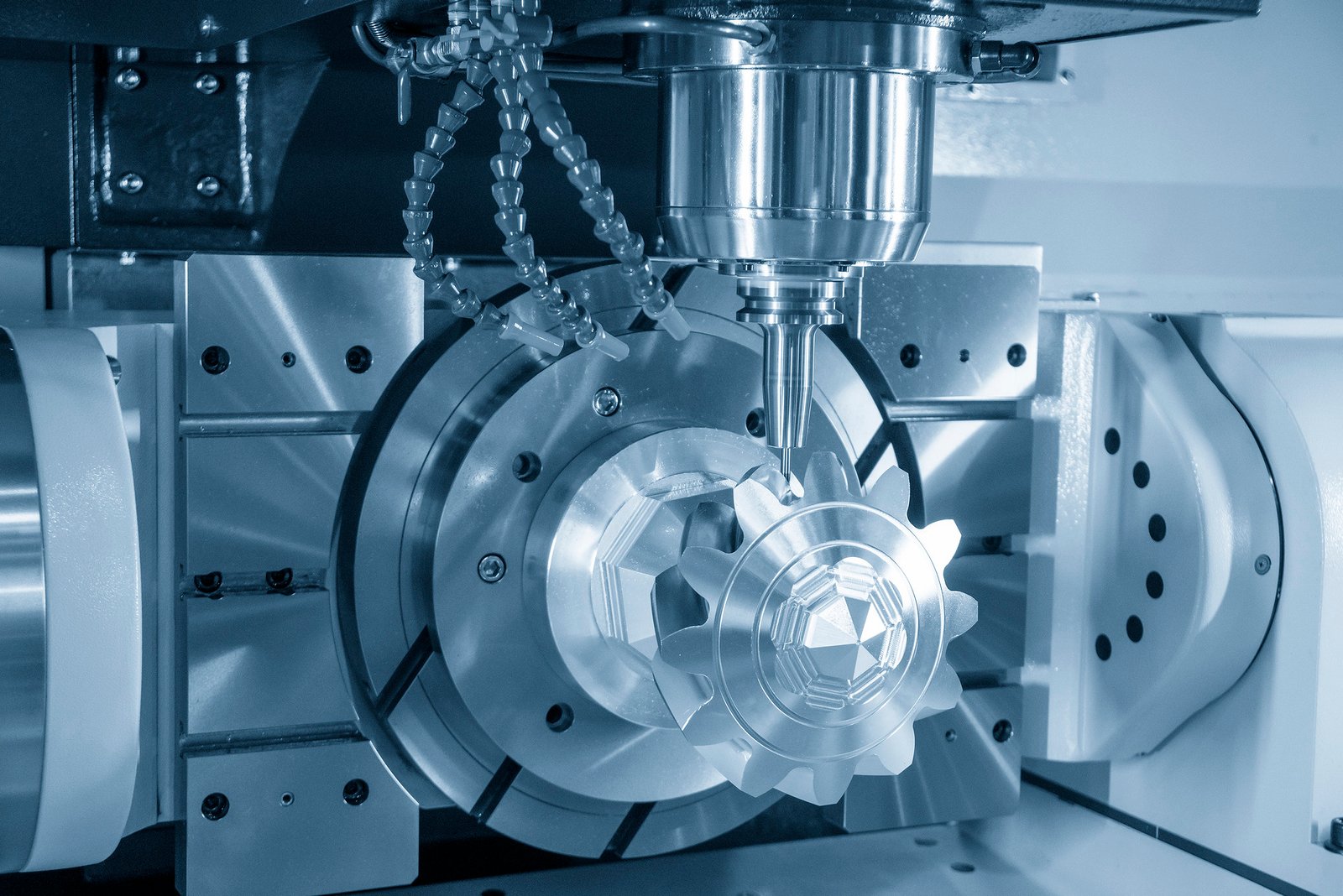

DEBO provide customers a one-stop solution for non-standard precision machining parts.

When it comes to fasteners, performance is everything. If the torque is not right, the product could fail, leading to costly problems for everyone involved.

Choosing the wrong stainless steel fastener could lead to early corrosion, structural failure, or customer complaints. The ISO 3506 standard helps avoid all that—if you

Many importers don’t realize their fasteners could fail EU customs checks—just because they contain restricted substances. Here’s what to watch out for before you ship.

Many buyers trust “ISO certified” fasteners, but they often don’t understand what this standard actually accepts—or rejects. ISO 3269 defines general acceptance criteria for mechanical

Hydrogen embrittlement is a hidden killer in fasteners. It quietly causes cracking, then sudden failure—especially in high-strength parts. But ISO 4042 helps control this risk.

Tapping seems simple. But in high-precision machining, one small mistake can scrap a whole batch. Are you really avoiding the hidden traps in tapping? The

High-strength fasteners play a vital role in modern industries such as mechanical engineering, automotive, construction, wind energy, and heavy machinery. These components must meet strict

In today’s globalized manufacturing landscape, the standardization of fastener dimensions plays a crucial role in ensuring product compatibility, reducing assembly errors, and simplifying procurement. Especially

In industries such as automotive, construction, heavy machinery, and energy, fasteners are critical components that must maintain integrity even in harsh environments. Corrosion of fasteners

In precision manufacturing industries, fasteners play a critical role in securing and assembling components. Their surface and internal cleanliness directly impact the performance, reliability, and

In the world of industrial manufacturing and surface treatment, shot blasting is a highly effective and widely used technique. It is primarily applied to clean

In modern industrial manufacturing, surface treatment plays a critical role in ensuring product performance, durability, and appearance. Among various surface processing techniques, sandblasting—also known as

Send us a message if you have any questions or request a quote. Our team will give you a reply within 24 hours.

Tel: +86(0)21 5830 6756 – 1006

Fax: +86(0)21 5830 6756 – 1012

E-mail: info@updebo.com

Address: Room 607, No.1, 1.000 Lane, Jianchuan Road, 200240 Minhang District, Shanghai, China

We will contact you within 1 working day, please pay attention to the email with the suffix “@updebo.com”.